c

24

c

23

c

22

c

21

c

20

c

19

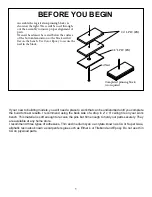

Use the registration pins to assemble the

landing gear slot, always assemble these

parts with the labeled side UP. Since these

parts are handed, it’s a good idea to assem-

ble both sets at the same time, then select

the correct one for the wing panel you are

working on. This will consist of two W2-B

parts and one W2-C. Place one of the W2-B

parts on the pins and glue another W2-B to

it. Install and glue a W2-C to this and then

install this assembly to the outboard side

of W2. Note that the W2-B/C assembly is

handed and a RIGHT handed version must

be assembled for the right wing.

The landing gear block consisting of two W2-B and one

W2-C being laminated together using the registration pins.

Note that when laminating handed parts, always laminate

them with the labeled side up. This will prevent you from

laminating two of the sane hand.

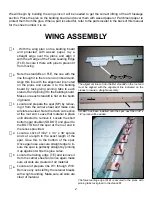

Install and glue W3-A to the outboard side

of W3.

Install and glue W4-A to the outboard side

of W4.

As cut, the trailing edge should be flush with

the top of the ribs between the root and W7.

However it will be slightly proud of the trail-

ing edge at the back edge. Sand the top of

the trailing edge until it is flush with the ribs

completely. Then install and glue the Trail-

ing Edge Sheeting (TES) to the trailing edge

and ribs between the root and W7. Note that

TES will be flush with the front side of the

trailing edge only between ribs W4 through

W7. It will be set back 1/16” between the

root and W4.

Steps 19, 20 and 21, laminating the gear block assembly

as well as W3-A and W4-A, clamps are used to insure good

contact with the paring ribs.

Assemble one TCS TOP and one BCS to

form the center section sheeting. Glue this

assembly to ribs W1, W2 and W3 as well as

the trailing edge and the top of the spar.

Plane or sand the leading FLE to contour

with the leading edge of the ribs in prepara-

tion for sheeting the leading edge.

4

Top trailing edge (step 22) and top center section sheeting

(step 23) install and glued to the wing assembly.