22

10. Set the Period of Soft Start

When the Digital Display indicates

“Pb”, the gate opener is ready for setting period of soft start.

You can press the

“INC” or “DEC” button to set the period of soft start. There is 1-9 seconds available in setting.

Press the

“FUNC” button to store the data when the period is set. The Digital Display will indicate “PC”.

(Factory set is 3 seconds)

11. Set the Fast Running Period (FRP) to Achieve Soft Stop Function (SPP)

When the Digital Display indicates

“PC”, the Fast Running Period for opening or closing gate is adjustable by

pressing

“INC” and “DEC” buttons respectively, and the Soft Stop Function is achieved simultaneously.

The Soft Stop means the gate opener runs at slow speed during the last period before the gate completely

closes. The Soft Stop Period is unavailable by direct adjust but available through adjusting the Fast Running

Period.

There are two running speeds designed in program, i.e. Fast Running Speed and Soft Running Speed. The

Fast Running Period is adjustable from 1 to 28 sec. Factory default setting is 15 sec.

Since the GATE OPENING OR CLOSING RUNING PERIOD (GRP) = SOFT START PERIOD (STP) + FAST

RUNNING PERIOD (FRP) + SOFT STOP PERIOD (SPP), the SPP could be extended by shortening the FRP

when the GRP and STP are fixed. In other words, SPP = GRP

–STP–FRP.

Similarly, the Soft Stop Period (SPP) can be shortened through extending the Fast Running Period (FPP).

E.g.

When the Soft Start Period (STP) is set at 3 sec, and the GRP is 23 sec (you can calculate the GRP period

by yourself, from” the arm actuator starting to move

on the fully open position

” to “the arm arriving

at the

fully close position

”), how can we get 4 sec of Soft Stop Period (SPP) to meet the requirement? The answer is

clear, i.e. we may set the Fast Running Period (FRP) at 16 sec (23

– 3 – 4 =16 sec).

12. Return to Factory Set

When the Digital Display indicates

“Pd”, press and release the “INC” or “DEC” button. All data will return to

factory set, the Digital Display indicates

“dF”.

13.

If all of data is set and no other change needed, press

“FUNC” Button. “- -” appears on the Digital Display,

and the opener enters standby mode.

Indicate Illustration on the Digital Display When Gate Opener is Running

The left image on Digital Display symbolizes motor of gate opener

2

when the gate opener is running. The right

image on Digital Display symbolizes motor of gate opener

1.

When the motor is run to gate -open direction or gate -close direction, the image

on Digital Display indicates “n”

or “u” respectively.

When the motor is not running, the Digital Display indicates

“- -”.

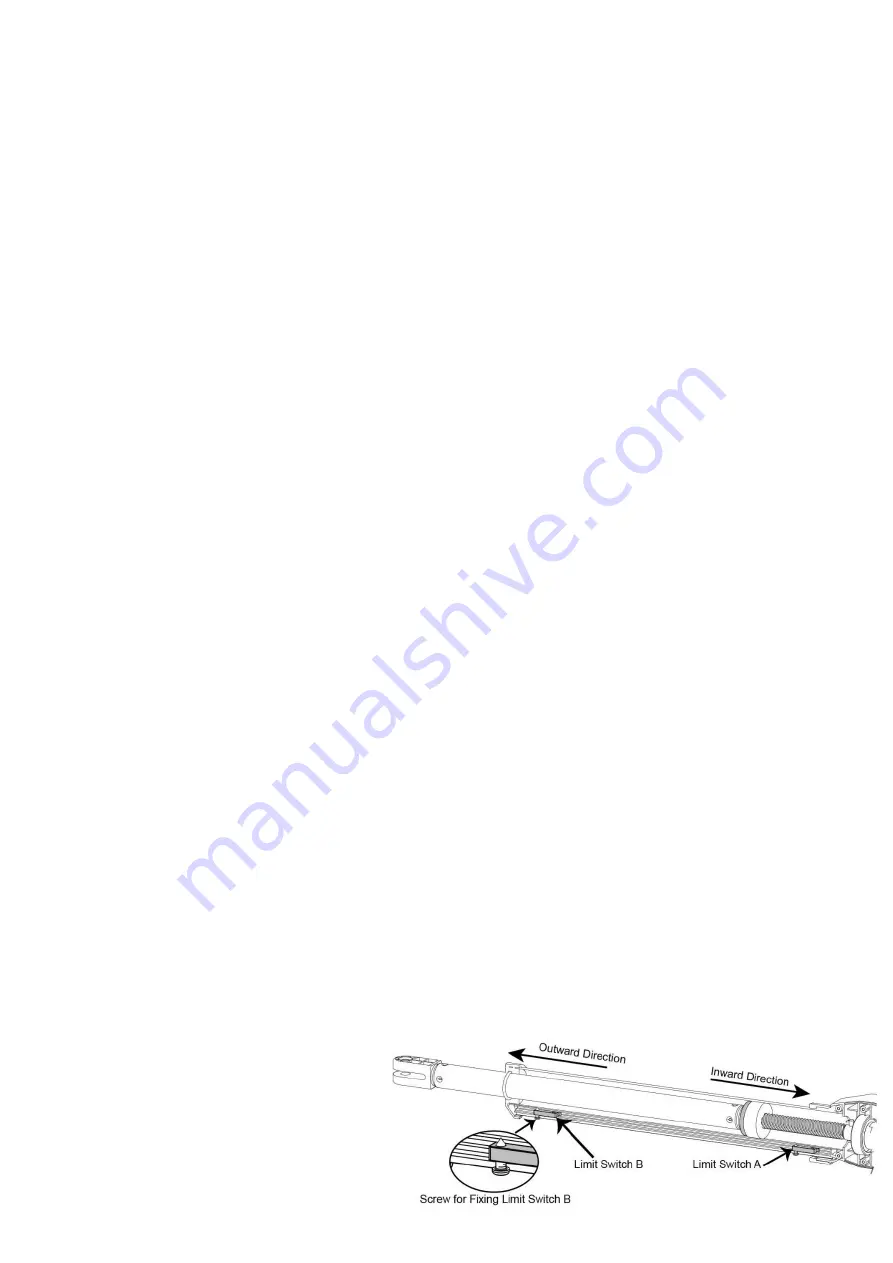

Adjusting the Limit Switch

Note: Before adjusting the limit switch, refer to the chapter of “Install the Opener on the Gate”, and make sure that

the rod is fully retracted when the gate is in the fully open position (for Pull-to-Open installation), or in the fully closed

position (for Push-to-Open installation). Make sure that currently the rod is fully retracted.

Note: The position of Limit Switch A was fixed in

factory, do not adjust it again.

1 For Pull-to-Open Installation, adjust the limit

switch B to determine the closed position:

Turn on power to operate the gate opener, then

the arm extends to close the gate.

If the arm closes over the desired closed position,

Summary of Contents for KD902

Page 6: ...3 KD902 Parts List Accessories Parts Included in some models refers to the actual package...

Page 18: ...15 Connecting of the Control Board...

Page 28: ...25 Quick Setting Guide...

Page 29: ...26...

Page 30: ...27...

Page 31: ...28...