20

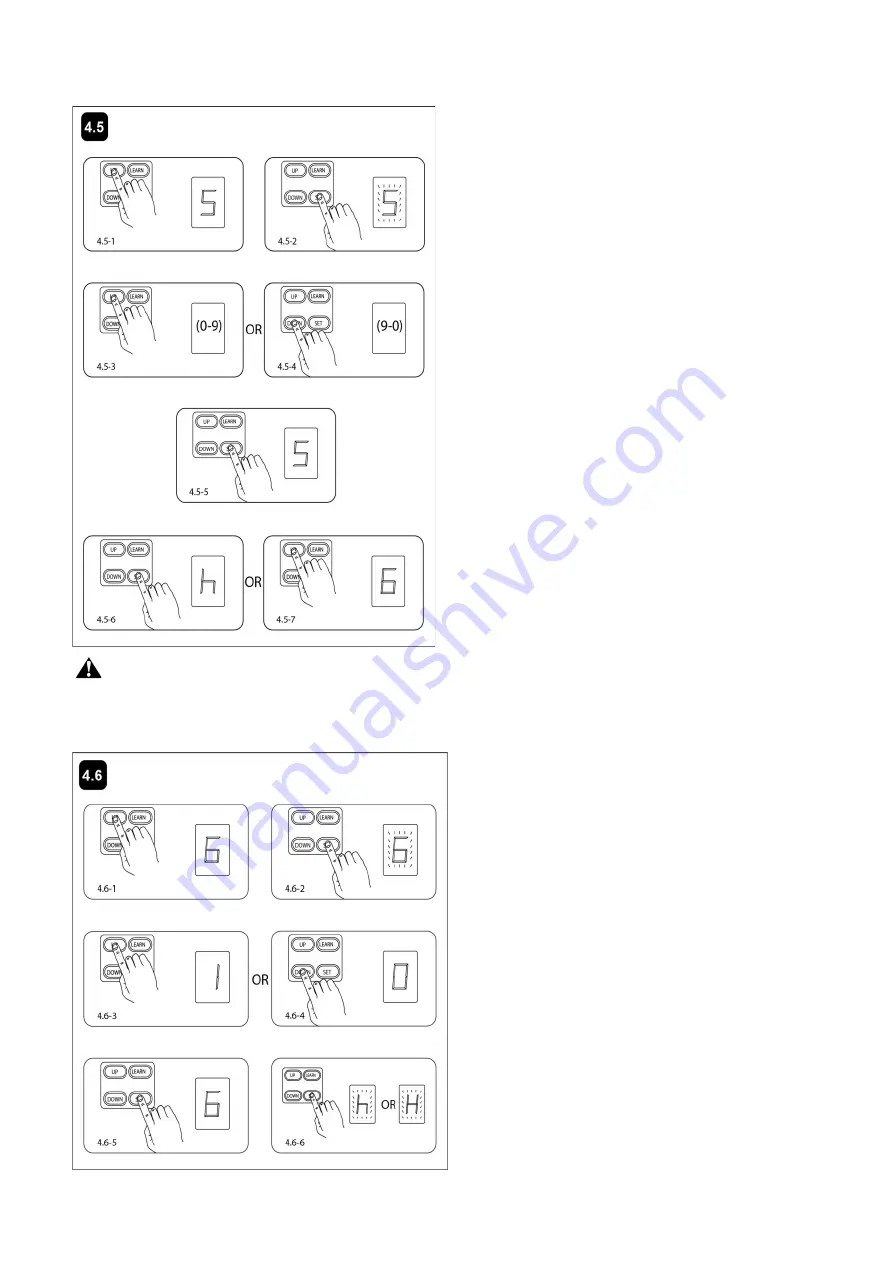

4.5 Setting the Automatic Closing Time

Important Note: When the auto close function is enabled, the photocell sensor is highly recommended to be

installed with the gate opener for safety.

4.6 Set the Safety Photocell Beam (SPB) System (Optional)

1. Press and hold SET button for more than 4 seconds.

The Digital Display indicates “1” (Skip if continuing

Closing Time Set after the Close Force Set is finished).

2. Press UP button and choose figure “5” (Pic.4.5-1).

Press and release SET button. “5” flashes in the Digital

Display (Pic.4.5-2). Now the unit enters into Setting the

Automatic Closing Time.

3. Press and release UP button. “

0

” –“9” flashes in the

Digital Display (default value is “

0

”, Automatic Closing

function is closed) indicating current automatic closing

time (Pic.4.5-3). The minimum time is 1 minute, 9

minutes maximum. Each time press and release UP

button, the figure is bigger by 1, and the timing increases

by 1 minute accordingly. Each time press and release

DOWN button, the figure is smaller by 1, and the timing

decreases by 1 minute accordingly (Pic. 4.5-4). When

the indication is “

0

”, it means the Automatic Closing

function is closed.

4. Press SET button to store the data when desired

Automatic Closing Time is set. “5” glows steadily in the

Digital Display (Pic.4.5-5). The unit is ready for setting

other parameter. Press SET button for seconds till “h”

appears in Digital Display (Pic.4.5-6). Now the Automatic

Closing Time has been set.

1. Press and hold SET button for more than 4 seconds.

The Digital Display indicates “1” (Skip if continuing SPB

Set after the Closing Time Set is finished).

2. Press UP button and choose figure “6” (Pic.4.6-1).

Press and release SET button. “6” flashes in the Digital

Display (Pic.4.6-2). Now the unit enters into Setting the

Safety Photocell Beam (SPB) Function.

3. Press and release UP button. The Digital Display

indicates “1” (SPB is available).(Pig.4.6-3) Press and

release DOWN button. The Digital Display indicates “

0

”

(SPB is null) (Pig.4.6-4).

4. Press SET button to store the data when SPB is set.

“6” glows steadily in the Digital Display. (Pig.4.6-5).The

unit is ready for setting other parameter. Press SET

button for seconds till “H” or “h” appears in Digital

Display (Pig.4.6-6). Now Setting the SPB Function is

finished.

NOTE: The unit doesn’t work until the SPB is equipped

and “1” is set in the LED.

Summary of Contents for MultiRuta CASAR 800

Page 28: ...25 5 Quick Setting Guide 5 1 Program your Opener Remote 5 2 To Erase all remote Control codes...

Page 29: ...26 5 3 Unit Setting...

Page 30: ...27...

Page 31: ...28...

Page 32: ...29...