9

Important:

* Check that the rack teeth must engage the gear teeth throughout their full thickness. If not, adjust the

position of the opener or/and place a few shims between the rack and gate.

* Manually slide the gate leaf to ensure the rack is proper on the gear of opener, weld the second nut.

* Repeat same steps of first rack section to install the rest rack sections until proper length is reached.

* Cut away any excess of the rack (Note: rack length must be longer than actual travel of the gate to

accommodate limit switch brackets on each gate side.)

* Thoroughly fasten the four nuts as well as spring washers onto expansion bolt tightly, enabling the opener

is firmly secured on the concrete pad during the whole gate travel.

Install the magnets for Limit Switches

Before install limit switch, make sure the gate opener is put in manual operation. (the clutch connected with

gear shaft is disengaged) and the mains power supply is disconnected.

Position the two limit stop brackets approximately on the rack and move the gate by hand to fix them in

place.

Fit magnets bracket

Push the gate fully closed by hand. Locate and install the magnet bracket so that the opener will stop at the

desired close position when the close limit switch approaches it.

Push the gate fully open by hand. Locate and install the magnet bracket so that the opener will stop at the

desired open position when the open limit switch approaches it.

The higher magnet bracket must be installed at left side and lower magnet bracket must be installed

at right side from the view inside of property.

Finally adjust the magnet to the proper position by moving

the gate with the motor.

The magnet should be 20-30mm away from the magnetic limit switch.

If it is too

far away, the switch will fail to work. The distance between the magnet and the opener should be 10-15mm

with the opener cover on. Adjust the position of the magnet until the positions of the opening and closing

meet the requirement.

Important Note:

Please note the two magnet brackets (fixed plate) are different: one is higher and the other

is lower.

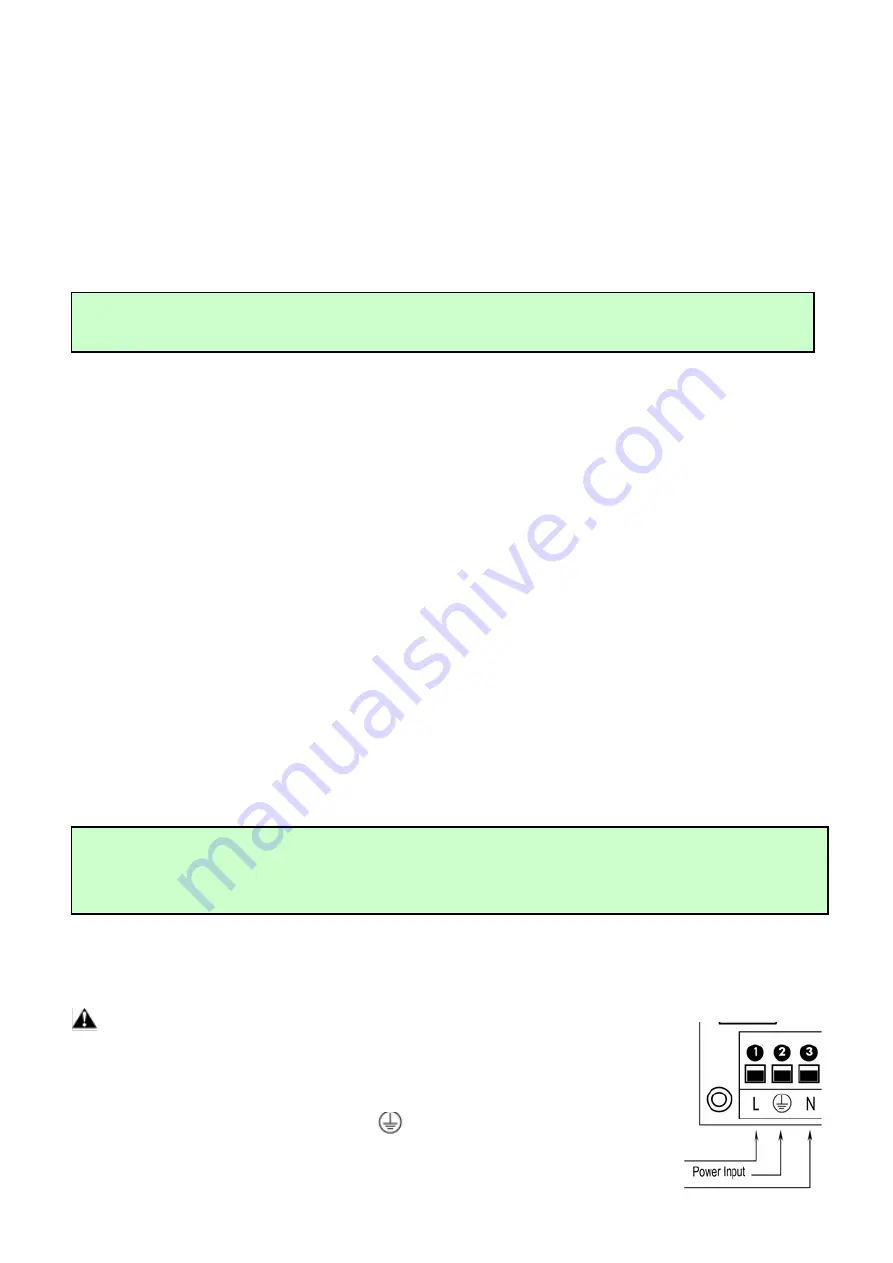

Connecting of Power Supply

WARNING: NEVER connect the gate opener to the power outlet before all

the installations have been done.

The power supply cord should be at least 3×0.75mm2 (3C×18AWG). Connect the

live wire and neutral wire to the “L” (1#) and “N” (3#) terminal of the control board

respectively; and connect the earth wire to “

” (2#) terminal of the control board.

NOTE: The power supply cord is not included in the package.

NOTE:

Leveling pad & bolts may be used for uneven ground or areas where

requires higher positions to fix the racks.

Warning:

Improper magnets installation may cause the gate crash into end barrier,

which is very dangerous !