2

Thank you for purchasing our sliding gate opener. We are sure that the products will be greatly satisfying as

soon as you start to use it.

The product is supplied with a user’s manual which encloses installation and safety precautions. These

should be read carefully before installation and operation as they provide important information about safety,

installation, operation and maintenance. This product complies with the recognized technical standards and

safety regulations.

General Safety

WARNING! An incorrect installation or improper use of the product can cause damage to persons,

animals or properties.

• Scrap packing materials (plastic, cardboard, polystyrene etc.) according to the provisions set out by current

standards. Keep nylon or polystyrene bags out of children’s reach.

• This product was exclusively designed and manufactured for the use specified in the present

documentation. Any other use not specified in this documentation could damage the product and be

dangerous.

• The factory declines all responsibility for any consequences resulting from improper use of the product, or

use which is different from that expected and specified in the present documentation.

• Do not install the product in explosive atmosphere.

• The factory declines all responsibility for any consequences resulting from failure to observe Good

Technical Practice when constructing closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

• Disconnect the electrical power supply before carrying out any work on the installation. Also disconnect

any buffer batteries, if fitted.

• Fit an omnipolar or magnetothermal switch on the mains power supply, having a contact opening distance

equal to or greater than 3,5 mm.

• Make sure a residual current circuit breaker with a 30mA threshold is fitted before the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for closure (doors, gates etc.) and all

system components provided with an earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are needed to protect the area from any

danger caused by squashing, conveying and shearing.

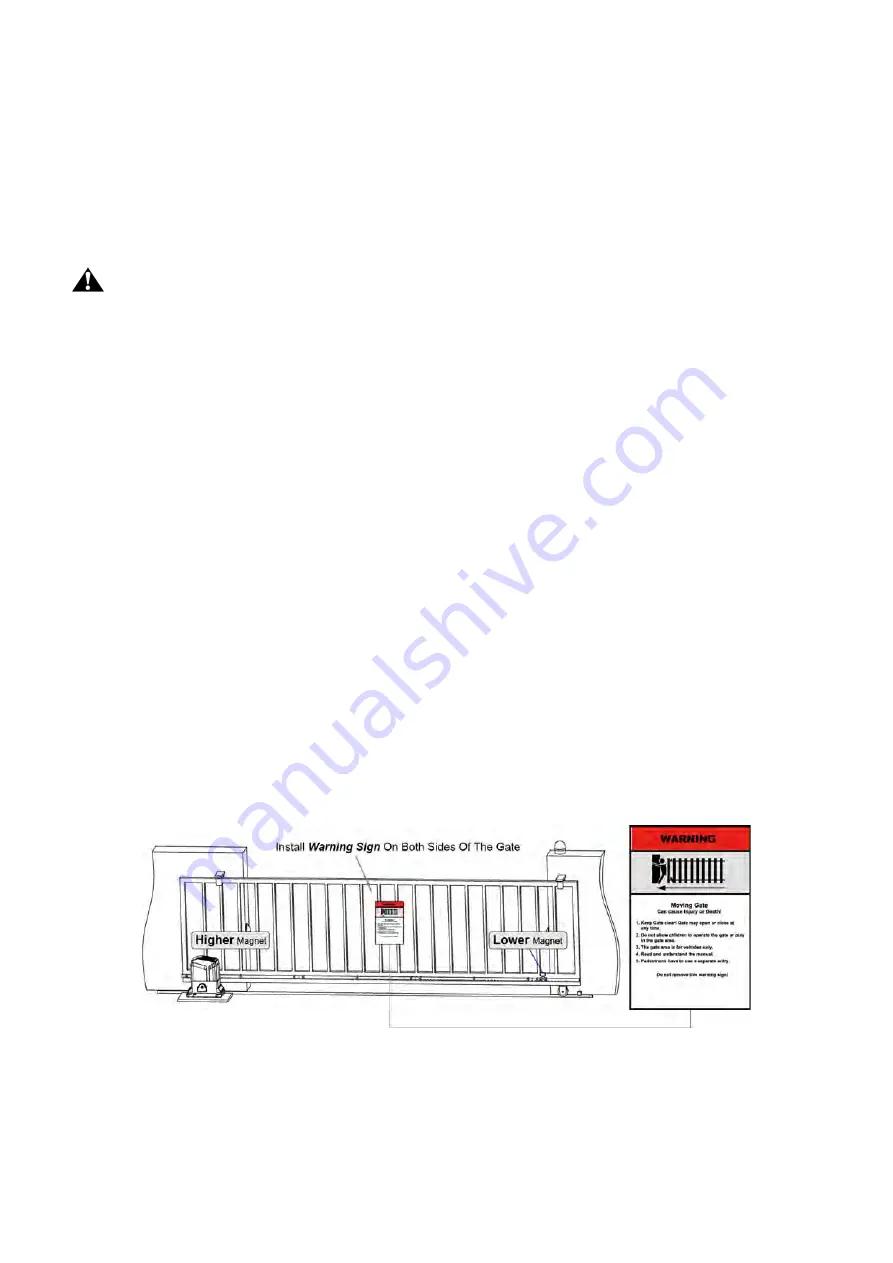

• Position at least one visible indication device, and fix a Warning sign to the structure.

• The factory declines all responsibility with respect to the automation safety and correct operation when

other supplier’s components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorized by the factory.

• Instruct the product user about the control systems provided and the manual opening operation in case of

emergency.