9

TOPEX.PL

INSTRUCTION MANUAL

74L214

cAUTiOn

: BEfORE fIRST USE Of THE TOOL REAd ALL mAINTENANcE ANd SAfETy RULES ANd fOLLOw THEm

cLOSELy. KEEP THE INSTRUcTION mANUAL fOR fUTURE REfERENcE.

TEchnicAL sPEcificATiOn

disc diameter

125 mm

Spindle rotational speed with no load

10 000 rpm

Air consumption

140 l/min (5cfm)

working pressure

6.3 bar (90 psi)

Air inlet

1/4”

weight

1.3kg

Noise emission within limits allowable by pr EN15744:1999.

Handle vibration level within limits allowable by EN08662-13:1997.

sAfETy rULEs

Always use safety glasses or goggles.

1.

The tool must be switched off prior to connecting air supply.

2.

disconnect the tool from air supply before disc replacement and all service and maintenance actions.

3.

The tool must be clean and lubricated at all times. daily lubrication is necessary to avoid corrosion inside the tool and

4.

potential faults.

do not wear watch, rings, bracelets or loose clothes when using air tools.

5.

connect the tool with wall or compressor connector only with light-weight spiral hose. do not use quick-couplers to

6.

connect hose and the tool, because the connection may be broken due to vibrations.

do not overload the tool. The tool must operate at optimal speed to achieve its maximal efficiency.

7.

do not increase pressure above the level recommended by the manufacturer. Overloading the tool may cause splitting of

8.

the tool body. Overloading also causes excessive wear of moving parts and emerging of potential faults.

To ensure safety and avoid possible damages of the tool or body injury, always put the tool away only after it stops

9.

completely.

Always fix the processed object, it allows to operate the tool with both hands.

10.

Always ensure the discs, caps, sockets and other items are designed for operation with this type of the tool. They also must

11.

be fixed properly and secured before connecting the tool to air supply.

Always wear appropriate protective mask or respiratory system protection when sanding, smoothing or cutting.

12.

Air sUPPLy

Ensure the air valve (or trigger) is in the Off position before connecting the tool to air supply.

Required air pressure is 6.3 bar (90 psi), and air flow according to technical specification.

cAUTiOn

! Air supply must be clean and its pressure must not exceed 6.3 bar (90 psi) during sander operation. Too great air

pressure and pollution shortens the tool life due to excessive wear of mating parts. drain water from the air tank on a daily

basis. water getting into air circuit will damage the sander.

Increase air pressure appropriately to compensate effect of excessively long hoses (above 8 metres). Hoses with 8 mm internal

diameter are recommended.

Protect hose against heat, oil and sharp objects. check wear of the hose and protection of all connections.

LUbricATiOn

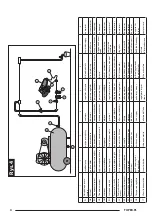

Use of automated inline filter-regulator-lubricator unit is recommended (fig. 4). It prolongs the tool life and ensures appropriate

operation. check lubricator on a regular basis and fill it up with oil for air tools.

you can adjust inline lubricator by placing a sheet of paper in front of outlet connectors. Next fully open the throttle for

approximately 30 seconds. The lubricator is properly set, when a small stain of oil appears on paper. Prevent emerging of too

great quantity of oil.

Summary of Contents for 74L214

Page 2: ......

Page 12: ...12 TOPEX PL 10 11 12 6 3 6 3 8 8 4 30 30 2 6 4...

Page 13: ...13 TOPEX PL...

Page 15: ...15 TOPEX PL 6 3 6 3 8 8 4 30 30 4...

Page 16: ...16 TOPEX PL...

Page 36: ...36 TOPEX PL 4 30 30 2 6 4...

Page 37: ...37 TOPEX PL...