BTA User Guide

Topling Prnjavor

Page 38

5. INSTALLATION OF FURNACE

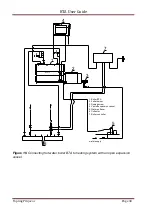

5.1. Connecting furnace to the central

heating system

Furnace installation should be done by qualified and authorised personnel.

Before the furnace is connected to the existing heating system, the heating system must

be thoroughly rinsed to remove dirt and sediment.

Dirt and sediment are normally collected in the furnace and can lead to localized

overheating, noise and corrosion. For damages arising out of it, your warranty will be void. In the

present case strainer should be mounted.

Furnace is connected to district heating installation through the initial and backflow route.

When connecting the furnace, any stretching that might be caused by pipework should be

avoided. The weight of the pipe lines must be handled by the supporters. All connections and

fittings on the boiler should be mounted so that it is possible to clean boiler smoothly. If possible,

air vent should be set just above the boiler at the initial route.

Connecting pipelines should be made by welding. Flanged connections are only allowed at

the point where the fittings are connected with pipelining.

All heat consumers or heating circuits must be connected to the extensions of initial and

backflow route. Do not attach to the safety cables or other accessories. It is recommended to

install a shut-off parts so that water does not have to be discharged from the entire installation

during the later works on the furnace and the heating circuit.

ATTENTION: When installing the pump, the direction of the pumps must be taken into

account.

The boiler is connected to the water supply system by flanges. Boiler filling is not

performed if the ambient temperature is below 5° C.

To verify the tightness of the boiler testing is performed at a pressure of 3 bars in

the production process, and the same procedure is repeated before and after the

assembly on the spot. What is done on-site is a visual inspection of the boiler, check of

the manometer so that charging complete installation can be proceeded. Open the door

to check the boiler operation.

If no pressure drop occurs during rehearsals, then you can proceed further

installation.

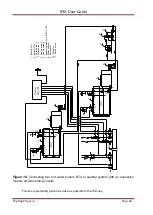

ATTENTION: Safety distribution line and security backflow route must be without closing

device.

Safety cables must not show any narrowings and must be laid to the expansion vessel

with such a climb to be provided with water circulation and to be prevented from collecting the air.

When setting up a parallel group of multiple systems, one or both of the cables as a

common (safety distribution or saftey backflow route) may be extended. To prevent the lowering

Summary of Contents for BTA1000

Page 70: ...BTA User Guide Topling Prnjavor Page 70...

Page 71: ...BTA User Guide Topling Prnjavor Page 71...

Page 72: ...BTA User Guide Topling Prnjavor Page 72...

Page 73: ...BTA User Guide Topling Prnjavor Page 73...

Page 74: ...BTA User Guide Topling Prnjavor Page 74...

Page 75: ...BTA User Guide Topling Prnjavor Page 75...

Page 76: ...BTA User Guide Topling Prnjavor Page 76...

Page 77: ...BTA User Guide Topling Prnjavor Page 77...

Page 78: ...BTA User Guide Topling Prnjavor Page 78...

Page 79: ...BTA User Guide Topling Prnjavor Page 79...