Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 13 --

Figure 2. Boiler

TKP

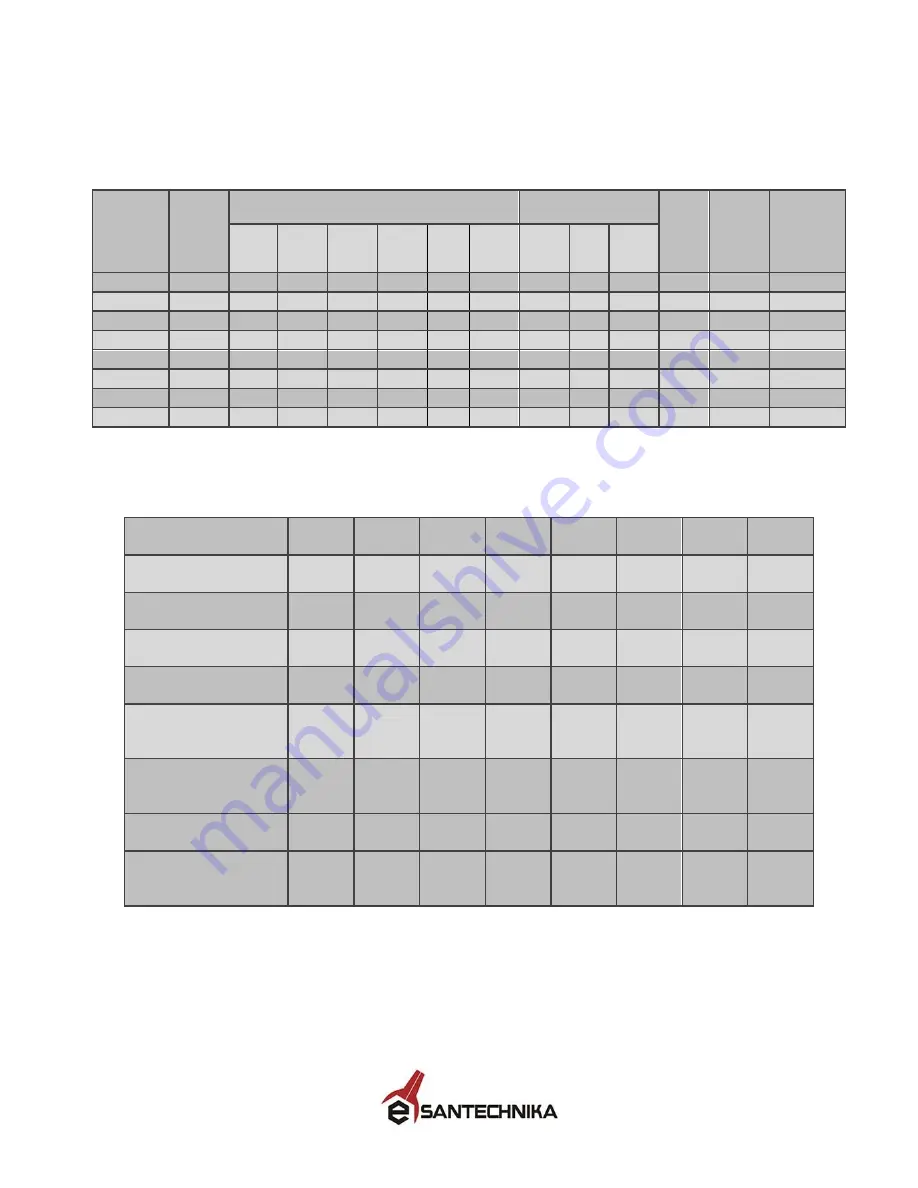

TYPE

Power

rating

s

[kW]

DIMENSIONS

[mm]

CONNECTIONS

[col]

Draft

[Pa]

Mass

of the

boiler

[kg]

Water

Volume

inside

boiler

[l]

A

B

C

D

E

H

R1

R2

R3

TKP 20

20

465

705

1142

160

190

810

5/4

1/2

3/4

21

235

80

TKP 25

25

465

730

1250

160

190

950

5/4

1/2

3/4

22

258

85

TKP 30

30

495

775

1320

180

190 1030

5/4

1/2

3/4

23

305

109

TKP 35

35

550

785

1355

180

190 1040

5/4

1/2

3/4

25

336

135

TKP 40

40

590

760

1390

180

190 1050

5/4

1/2

3/4

26

362

140

TKP 50

50

710

785

1430

180

190 1090

5/4

1/2

3/4

28

380

150

TKP 65

65

748

890

1375

200

190 1040

6/4

1/2

3/4

30

480

200

TKP 80

80

765

990

1375

200

190 1040

6/4

1/2

3/4

35

595

220

Table 3. Characteristic dimension of boilers TKP type

TIP

TKP

20

TKP

25

TKP

30

TKP

35

TKP

40

TKP

50

TKP

65

TKP

80

Maximum power

[kW]

20

25

30

35

40

50

65

80

Heat output range

[kW]

10-20

12-25

15-30

17-35

20-40

25-50

30-65

40-80

Maximum operating

pressure [bar]

3

3

3

3

3

3

3

3

Maximum operating

temperature

[°C]

90

90

90

90

90

90

90

90

Operating

temperature

interval

[°C]

70-90

70-90

70-90

70-90

70-90

70-90

70-90

70-90

Class of the boiler

according to EN

303-5

3

3

3

3

3

3

3

3

Necessary draft

[Pa]

21

22

23

25

26

28

30

35

Temperature of flue

gases

[°C]

-

Maximum

250

250

250

250

250

250

250

250

Table 4. Technical data

Fuel

The boiler is intended for solid fuel combustion (firewood, wooden briquettes, wood waste,

lignite, coke, coal. Its design allows to feed large pieces of wood.