10

Lockout Procedure

Purpose

This procedure establishes the minimum requirements for the lockout of energy that could cause injury

to

personnel by the operation of lifts in need of repair or being serviced. All employees shall comply with this procedure.

Responsibility

The responsibility for assuring that this procedure is followed is binding upon all employees and service personnel from

outside service companies (i.e., authorized installers, contactors, etc.). All employees shall be instructed in the safety

significance of the lockout procedure by the facility owner/manager. Each new or transferred employee along with

visiting outside service personnel shall be instructed by the owner/manager (or assigned designee) in the purpose and use

of the lockout procedure.

Preparation

Employees authorized to perform lockout shall ensure that the appropriate energy isolating device (i.e., circuit breaker,

fuse, disconnect, etc.) is identified for the lift being locked out. Other such devices for other equipment may be located in

close proximity of the appropriate energy isolating device. If the identity of the device is in question, see the shop

supervisor for resolution. Assure that proper authorization is received prior to performing the lockout procedure.

Sequence of Lockout Procedure

1) Notify all affected employees that a lockout is being performed for servicing or maintenance and that the lift must be

shut down and locked out to perform the servicing or maintenance

2) Unload the subject lift (remove vehicle). Shut it down and assure the disconnect switch is “OFF” if one is provided on

the lift.

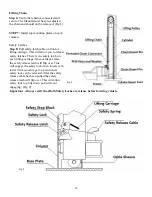

3) The authorized lockout person operates the main energy isolation device removing power to the lift being taken out of

service. Stored or residual energy (such as capacitors, springs, elevated machine members, hydraulic systems, air, or etc.)

must be dissipated or restrained by methods such as grounding, repositioning, blocking, bleeding down, etc.

If this is a lockable device, the authorized lockout person places the assigned padlock on the device to prevent its

unintentional reactivation. An appropriate tag is applied stating the person’s name, at least 3” x 6” in size, an easily

noticeably color, and states not to operate device or remove tag.

If this device is a non-lockable circuit breaker or fuse, replace circuit with a “dummy” device and tag it appropriately as

mentioned above.

4) Ensure that the equipment is disconnected from the energy sources’ by first checking that no personnel are exposed,

then verify the isolation of the equipment by operating the push button or other normal operating controls’ or by

testing to make certain the equipment will not operate. . Be sure to return any switches to the “OFF” position.

5) The equipment is now locked out and ready for the required maintenance or service.

Restoring Equipment to Service

1) Check the lift and the immediate area around the lift to ensure that nonessential items have been removed

(clear all tools, vehicles and personnel) and that the completion of all lift components are operationally intact.

2) The authorized person can now remove the lock (or dummy circuit breaker or fuse) and tag. Activate the energy

isolating device so that the lift may again be placed into operation.

Rules for Using Lockout Procedure

All employees are required to comply with the restrictions and limitations imposed upon them during the use of lockout.

The authorized employees are required to perform the lockout in accordance with this procedure. All employees, upon

observing a piece of lifting equipment which is locked out to perform servicing or maintenance shall not attempt to start,

energize, or use that machine or equipment. The Lockout Procedure should be used whenever the lift is being

repaired or serviced, waiting for repair when current operation could cause possible injury to personnel, or for any other

situation when unintentional operation could injure personnel. No attempt shall be made to operate the lift when the

energy isolating device is locked out.

Summary of Contents for QJY240C

Page 9: ...9...

Page 23: ...23 Fig 12 Fig 12...

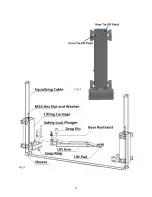

Page 32: ...34 Parts Diagram...

Page 33: ...35 Parts List...

Page 34: ...36 COMPANY INFO BACK PAGE...