11

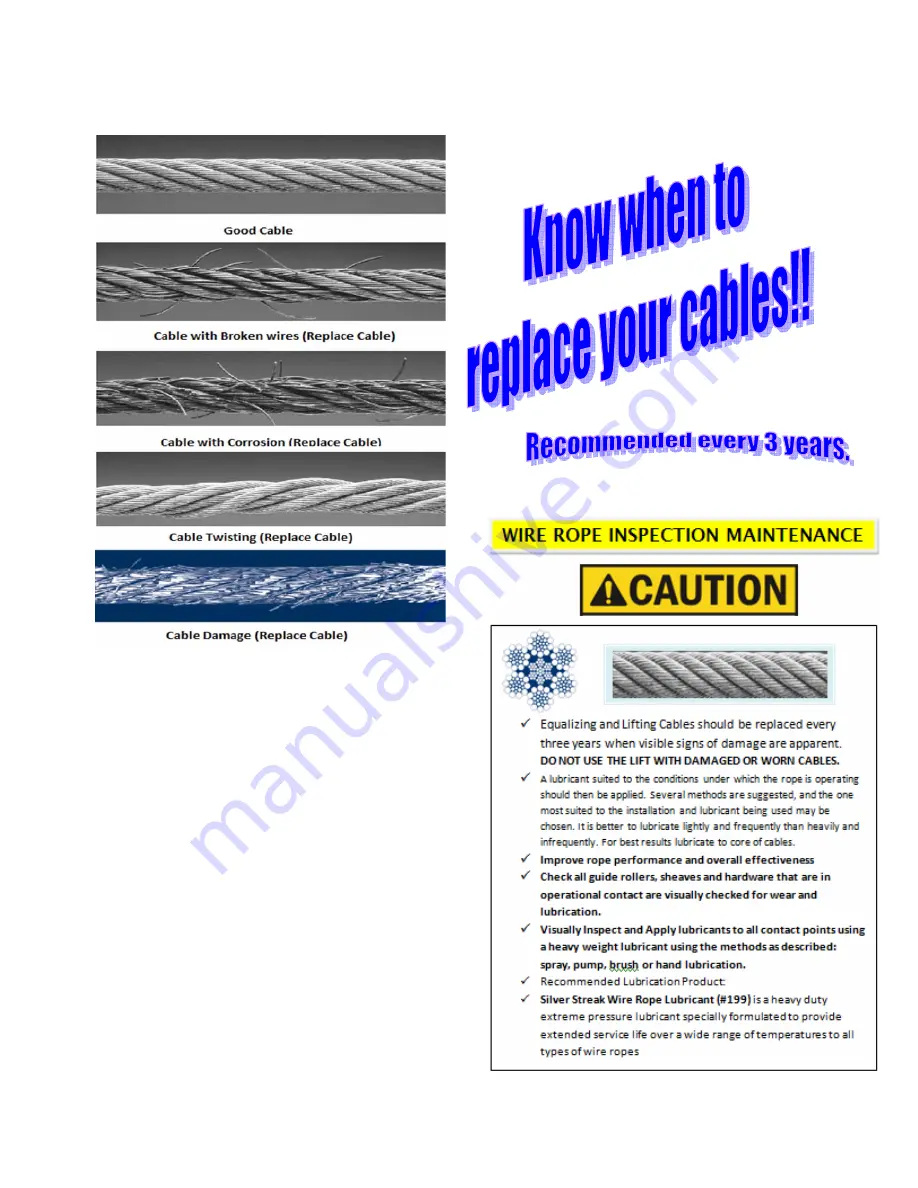

Wire Rope Inspection

(Knowing when to replace your cables!)

These pictures will help you assess when you will need to replace wire rope.

All

wire

rope,

sheaves

and

guide

rollers

in

continuous

service

should

be

observed

during

normal

operation

and

visually

as

per

the

scheduled

maintenance.

A

complete

and

thorough

inspection

of

all

ropes

in

use

must

be

made

as

below

and

all

rope

which

has

been

idle

for

a

period

of

a

month

or

more

should

be

given

a

thorough

inspection

before

it

is

put

back

into

service.

Factors

such

as

abrasion,

wear,

fatigue,

corrosion,

improper

winding

and

kinking

are

often

of

greater

significance

in

determining

if

a

wire

rope

is

usable.

Use

the

pictures

as

shown

as

guide

for

determining

when

to

replace

your

wire

rope.

Recommended

Lubrication

Product:

Silver

Streak

Wire

Rope

Lubricant

(#199)

is

a

heavy

duty

extreme

pressure

lubricant

specially

formulated

to

provide

extended

service

life

over

a

wide

range

of

temperatures

to

all

types

of

wire

ropes.

Check

all

guide

rollers,

sheaves

and

hardware

that

are

in

operational

contact

are

visually

checked

for

wear

and

lubrication

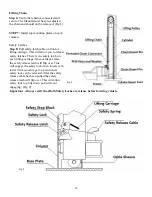

Summary of Contents for QJY240C

Page 9: ...9...

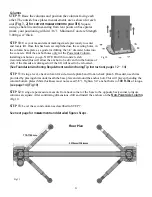

Page 23: ...23 Fig 12 Fig 12...

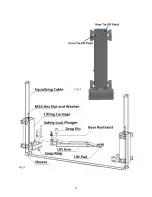

Page 32: ...34 Parts Diagram...

Page 33: ...35 Parts List...

Page 34: ...36 COMPANY INFO BACK PAGE...