5

Operator Training and Safe Practices

Precautions and Safety should always be followed when Installing and Operating this lift.

READ AND UNDERSTAND ALL SAFETY INSTRUCTIONS

AND DECALS INCLUDED ON AND WITH THE LIFT.

READ AND FOLLOW ALL SAFETY WARNING PROCEDURES

IN THIS MANUAL BEFORE OPERATING LIFT.

·

ONLY TRAINED and AUTHORIZED PERSONNEL should operate the lift. Do not allow

customers or unauthorized personnel to operate the lift or remain in the lift area.

·

Review regularly the safety rules and guidelines with personnel. All non-trained personnel

should be kept away from work area. Never let non-trained personnel come in contact

with, or operate lift.

·

Understand the vehicle lift operating controls before use.

·

Do not leave the operational controls while the lift is still in motion.

·

Do not stand in front of the vehicle or in the bay when vehicle is being loaded or driven

into position.

·

Do not attempt to work on the vehicle or go near vehicle when lift is being raised or

lowered.

·

Be aware. Watch what you are doing. Use common sense.

·

Stay clear of lift when raising or lowering vehicle.

·

Clear the area if vehicle is in danger of falling

·

Keep hands and feet clear. Remove hands and feet from any moving parts. Keep feet clear

of lift when lowering to avoid bodily harm or any pinch points.

·

Do not raise or lower the vehicle unless tools, materials and people are clear. Clean up

grease and oil spills immediately.

When the lift is being lowered, make sure everyone is

standing at least six feet away. Be sure there are no jacks, tools, equipment, left under the lift

before lowering. Always lower the vehicle down when

·

Inspect for damaged parts. Do not use lift if any components are broken or damaged.

Check all moving parts for any type of damage that may affect misalignment or operation

of lift.

·

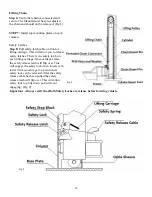

INSPECT THE LIFT DAILY

. Do not operate if potential problems have been identified or lift

malfunctions. Do not operate if lift has damaged or broken components. Never walk or work

under the lift unless all safety locks are completely engaged. A daily inspection of the lift

should be completed prior to its any use. Safety mechanisms, operating controls, lifting arms,

ramps and any other critical parts should be inspected prior to using the lift.

·

ALWAYS KNOW YOUR LOAD LIMIT.

Use caution so that you do not overload the lift. It

is important that you know the load limit. To check the rated capacity, decals are located

on one of the lift columns or contact the manufacturer. The hydraulic system on this lift is not

designed to be a load holding device. Mechanical safety locks must be engaged before

proceeding under the lift, with vehicle servicing, or system maintenance. Never override

operating controls. This is unsafe and will void the warranty, before driving a vehicle between

the columns, position all arms to insure unobstructed entry. Do not hit or run over arms as this

could damage the lift and/or vehicle.

·

Always make sure you have proper overhead clearance

Summary of Contents for QJY240C

Page 9: ...9...

Page 23: ...23 Fig 12 Fig 12...

Page 32: ...34 Parts Diagram...

Page 33: ...35 Parts List...

Page 34: ...36 COMPANY INFO BACK PAGE...