PowerSlide 24

ENGLISH

4 7

8

7.5 DIRECTION OF MOVEMENT CHECK

RISKS

PERSONAL PROTECTIVE EQUIPMENT

F

Disconnect power to the system before making connections

L

i

The operations described in this section are essential for the proper

operation of the gear motor.

1. Move the gate manually to its half-travel position and restore

automatic operation (§ ).

2. Make sure that both the FCC and FCA LEDs are lit.

3. Check that the magnetic limit switches are in the correct position

(§ ).

4. Check that the

dI

function in Basic Programming (§ -

) is set

correctly.

5. Turn the electronic board off and on again using the circuit breaker.

6. Open the gate (OPEN A); check that the gate actually performs an

opening movement in correspondence with the status indicator

01

on the display.

7. If it doesn’t, invert the two electric motor phase wires: J6, terminals

14 and 15 (§ -

). Repeat the operations indicated in points 5 and 6.

8. Check that the gate stops automatically when both limit switches

are tripped. In particular:

-

the display must indicate status

03

or

04

in correspondence with

the opening limit switch.

-

the display must indicate status

00

in correspondence with the

closing limit switch.

7.6 FINAL OPERATIONS

RISKS

PERSONAL PROTECTIVE EQUIPMENT

1. Ensure that the forces generated by the leaf are within the limits

allowed by the standard. Use an impact curve gauge in ac-

cordance with standards EN 12453 and EN 12445. For countries

outside the EU, when there is no specific local standard, the force

must be less than 150 N static.

2. Ensure that the maximum manual moving force of the leaf is less

than 225 N.

3. Use appropriate signs to highlight the areas where residual risks

remain despite having implemented all safety measures.

4. Put up the ‘’DANGER: AUTOMATIC MOVEMENT’’ sign on the gate

in a visible position.

5. Put up the CE marking on the gate.

6. Complete the EC Declaration of Conformity of the machine and

the system Logbook.

7. Provide the owner/operator of the automation with the EC Decla-

ration, the system Logbook with the maintenance schedule and

the user instructions of the automation.

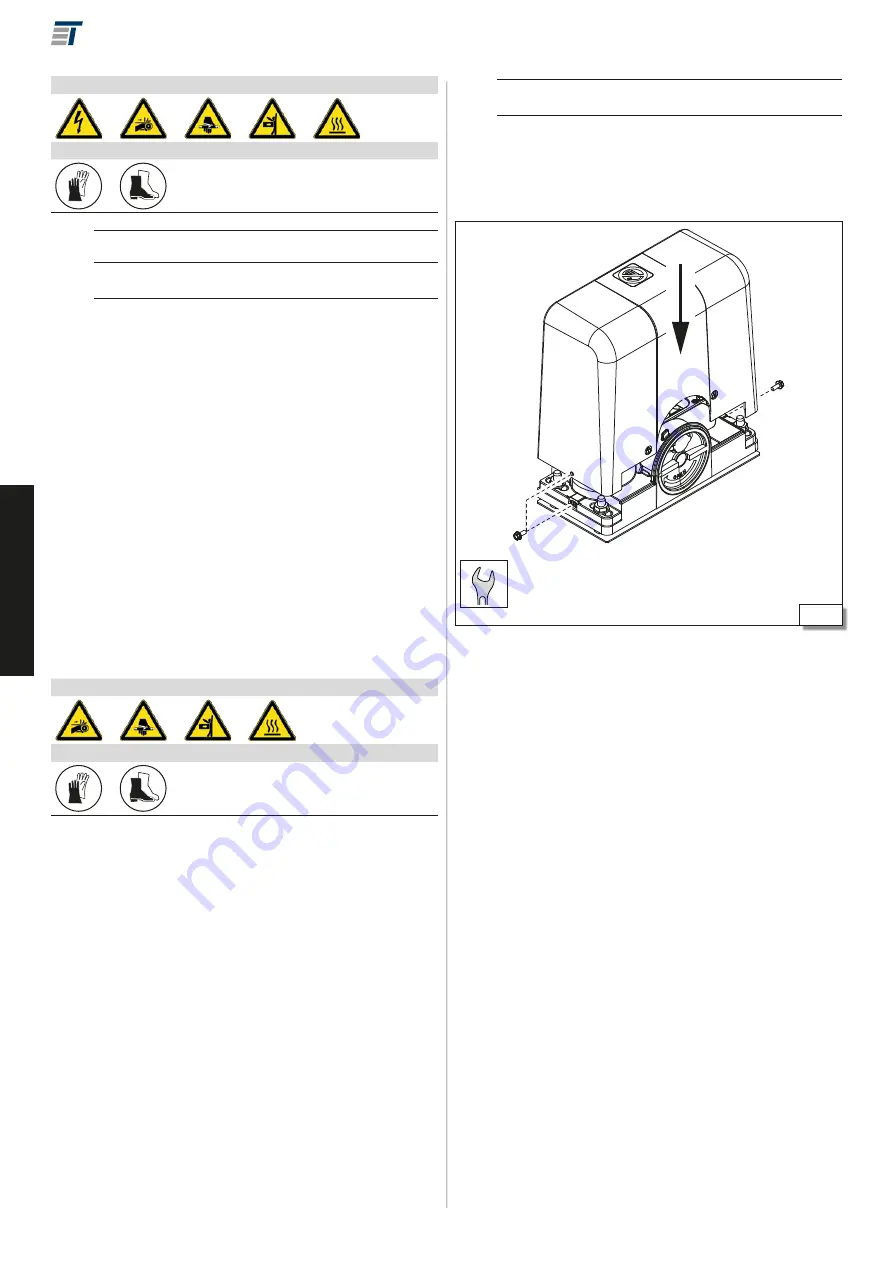

INSTALLING THE CASING

!

Mount the casing following the instructions in

4 7

: choose between

the hexagonal insert screws and the Allen screws provided, size M5.

Summary of Contents for POWERSLIDE

Page 1: ...POWERSLIDE GEBRAUCHSANLEITUNG D 913002 26 6 50 01 2018...

Page 2: ......

Page 31: ...POWERSLIDE INSTRUCTION MANUAL GB...

Page 32: ......

Page 61: ...POWERSLIDE GEBRUIKSAANWIJZING NL...

Page 62: ......

Page 91: ...PowerSlide 31...