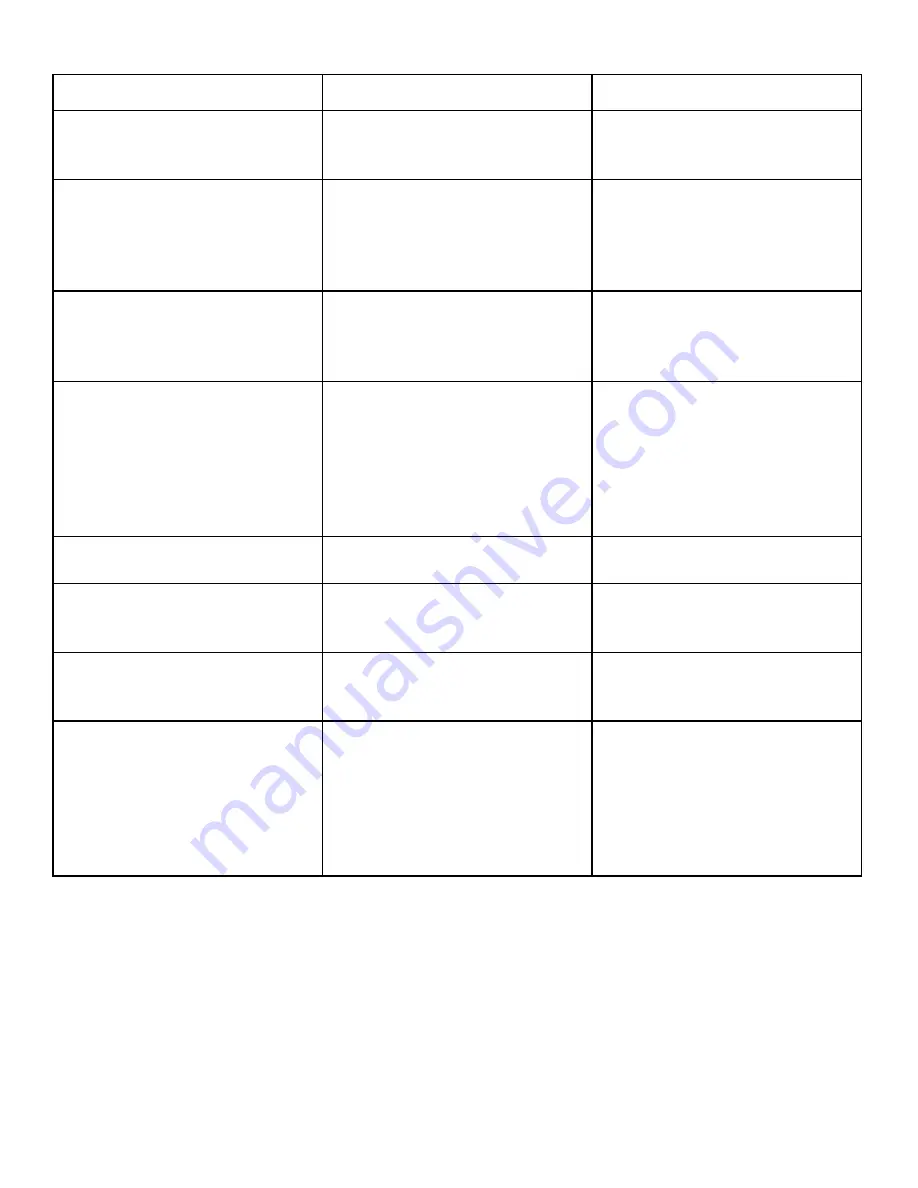

10

Problem

Possible Cause

Solution

Vacuum or pump will not run

Defective Cord(s).

Tripped building circuit breaker.

Inspect cord(s). Replace if

defective.

Reset circuitbreaker.*

Trips building circuit breaker

Circuit is overloaded.

Move cord to a different wall

outlet.*

Check plug end and cord for

damage.

Vacuum won’t run.

Vacuum switch not in the ON

posistion.

Water level too high.

Move Vacuum switch to the ON

position.

Drain some water out of the

tank.**

Pump won’t run

Pump switch not in the ON

position.

5 Amp circuit breaker is tripped.

Water level too low.

Low voltage (the pump will

not work if volage is less than

105VAC).

Move Vacuum switch to the ON

position.

Reset breaker.

Add water to tank.**

Check wall outlet for proper

voltage.

Pump tries to run and then blows

circuit breaker

Pump starts and stops

Sticking pump float.

Water level too low.

Ensure float moves smoothly on

float rod.

Add water to tank.**

Pump starts and sprays reduced

amount of fluid

Dirty cartridge filter.

Foam in tank

Remove and clean cartridge filter.

Add defoamer desighned for use

these extractors.

Low or no suction

Clogged or broken hose.

Loose connections.

Leave vacuum runnig for 1 minute

when finished cleaning to clear

hose. Check hose for breaks or

tears.

Make sure the in-line strainer is

properly tightened and fluid hose

connectors are fully seated.

TROUBLESHOOTING

*Check machine for dual circuit indicator light. If the light is not green, then you must move one cord to a

different outlet on another circuit.

**The tank must have at least 5gallons of water for unit to operate.

If using an extension cord, make sure it is in good condition, less than 70 feet long and AWG 12 gauge or

heavier.