12

ATTENTION:

Never charge a GEL battery

with a non suitable recharger.

Strictly follow the instructions

supplied by the batteries and

recharger manufacturer.

In order not to cause perma-

nent damages to the batteries,

it is necessary to avoid their

complete discharge, providing

for the recharging within a few

minutes after the batteries dis-

charge signal starts blinking.

NOTE: Never leave batteries

completely discharged even if

the machine is not used. In case

of traditional batteries, please

check the electrolyte level every

20 recharging cycles and even-

tually top them up with distilled

water.

ATTENTION:

1. The version (for example

A003) of software installed on

the machine.

2. The setting of the battery

check card is for the 24V ver-

sion:

GE 24: check card set for GEL

batteries

Pb 24: check card set for lead

batteries

For the recharge of the batteries

it is necessary to follow strictly

all the indications given by the

manufacturer/distributor. All the

installation and maintenance

operations must be carried out

by qualified staff.

Danger of

gas exhalations and emis-

sion of corrosive liquids. Fire

danger: do not approach with

free flames.

BATTERIES DISPOSAL

It is compulsory to hand over

exhausted batteries, classified

as dangerous waste, to an au-

thorized institution according to

the current laws.

BATTERIES CHARGE LEVEL

INDICATOR

TURNING THE KEY (9)

CLOCKWISE, ON THE DIS-

PLAY (1) APPEAR IN SE-

QUENCE THE FOLLOWING

INFORMATION:

3. The batteries charge level

indicator (1) is digital. The bat-

tery charge level starts at 90,

which indicates the 90% of the

total charge and decreases by

10 to 10. When the charge level

reaches 20%, the display starts

blinking, so you are about at the

end of working time.

After a few seconds from the

blinking of the four lines, the

brushes motor stops automati-

cally. With the remaining charge

it is anyhow possible to finish

the drying operation before pro-

ceeding to the recharge area.

ATTENTION:

HOUR METER

The machine is equipped with

an hour meter located on the

same display of the battery

charge level indicator (1). Keep-

ing the button (8) pressed for

more than 3 seconds, the first

data indicates the working hours

and after a few seconds the

working minutes are shown.

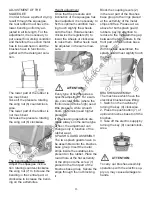

SQUEEGEE ASSEMBLY

1. Maintain the squeegee sup-

port (1) slightly lifted from the

floor.

2. Insert the two stud bolts (3)

placed on the upper part of the

squeegee (2) inside the slots on

the support.

3. Block the squeegee by rotat-

ing the lever (4) clockwise.

4. Insert the squeegee hose

(5) into its coupling, respecting

its position as indicated in the

figure.

https://harrissupplyind.com - To Order Parts Call 608-268-8080