13

BRUSHES ASSEMBLY

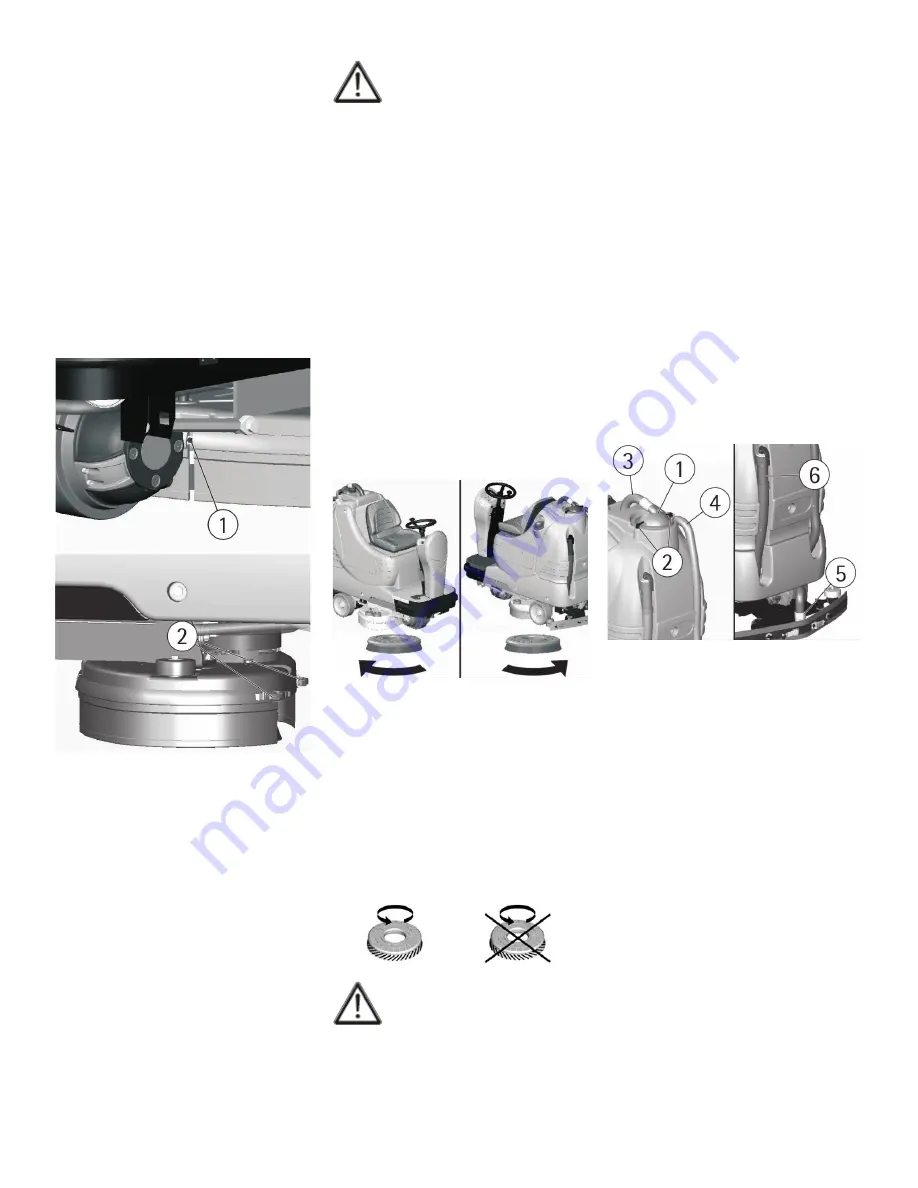

To assemble the brushes it is

necessary that the brushes

base is in the lifted position.

If it is not lifted, proceed as

follows:

Without the operator seated,

turning the key switch

clockwise, the display comes

on and after 3 seconds all

working groups come off

automatically and are lifted

from the floor.

Switch off the machine turning

the key counterclockwise.

spring until they get blocked.

The figure shows the rotating

direction for brushes coupling.

For a longer life of the brushes

we suggest to invert daily their

position. Whenever brushes

become de¬formed we

suggest to reassemble them in

the same position, in order to

avoid the different inclination

of the bristles to cause

excessive motor overload or

troublesome vibrations.

FLOOR CLEANING

RECOVERY TANK

Check that the cover of the

suction filter (1) is correctly

secured, after rotating the

levers (2) and that the suction

motor hose (3) is correctly

connected to it.

Verify also that the squeegee

hose couplings (4/5) are

correctly inserted into their

seats and that the exhaust

hose plug (6) placed in the

rear part of the machine is well

closed.

Block the coupling lever (2) in

the rear part of the brushes

base group to the ring placed

at the extremity of the metal

strip still free. Please act as

above for both splash guard

rubbers.

With the brushes assembled,

the splash guard must slightly

touch the floor.

For the disassembly it is

necessary to proceed inversely

with above-mentioned

operations.

ATTENTION:

ATTENTION:

To carry out brushes assembly

operations with the electric

supply on, may cause

damages to hands.

With the brushes base group

in lifted position, insert the

brushes into their plate seat

underneath the brushes base

turning them until the three

metal buttons are properly

seated in their slots; quickly

rotate the brushes to push the

button towards the coupling

spring until they get blocked.

The figure shows the rotating

direction for brushes coupling.

Use only brushes supplied

with the machine or the

ones indicated in the

paragraph “RECOMMENDED

BRUSHES”.

The use of other brushes can

compromise the result.

DETERGENT SOLUTION

TANK

The capacity of the detergent

solution tank is indicated in

the technical data.

Open the screw plug placed

in the left part of the machine

and fill the detergent solution

tank with clean water at a

maximum temperature of

122°F (50°C). Add the liquid

detergent in the percentage

and conditions recommended

by the manufacturer. To avoid

excessive foam, which could

cause problems to the vacuum

motor, use the minimum

percentage of detergent.

Screw down the plug to close

the tank.