4

Your new Tornado unit is a high quality, precision-made product. All parts used in the

manufacturing of this unit have passed rigid quality control standards prior to assembly. Please

safeguard the original receipt / invoice. If you experience any problems with your unit during the

warranty period, the original receipt / invoice will act as proof of purchase. Contact Tornado for

any warranty inquiries.

INTRODUCTORY COMMENT

This floor cleaning machine is used for the industrial and civil cleaning and is able to clean any

type of floor. During its forward movement, the combined action of the brushes and the detergent

solution removes the dirt which is aspirated through the rear suction assembly, giving a perfectly

dry surface.

The machine must be used only for such purpose. It gives the best performance if it is used

correctly and maintained in perfect efficiency. We therefore ask you to read this instruction

booklet carefully whenever difficulties arise in the course of the machine’s use. In case of

need, we ask you to contact our service department for all advice and servicing as may prove

necessary.

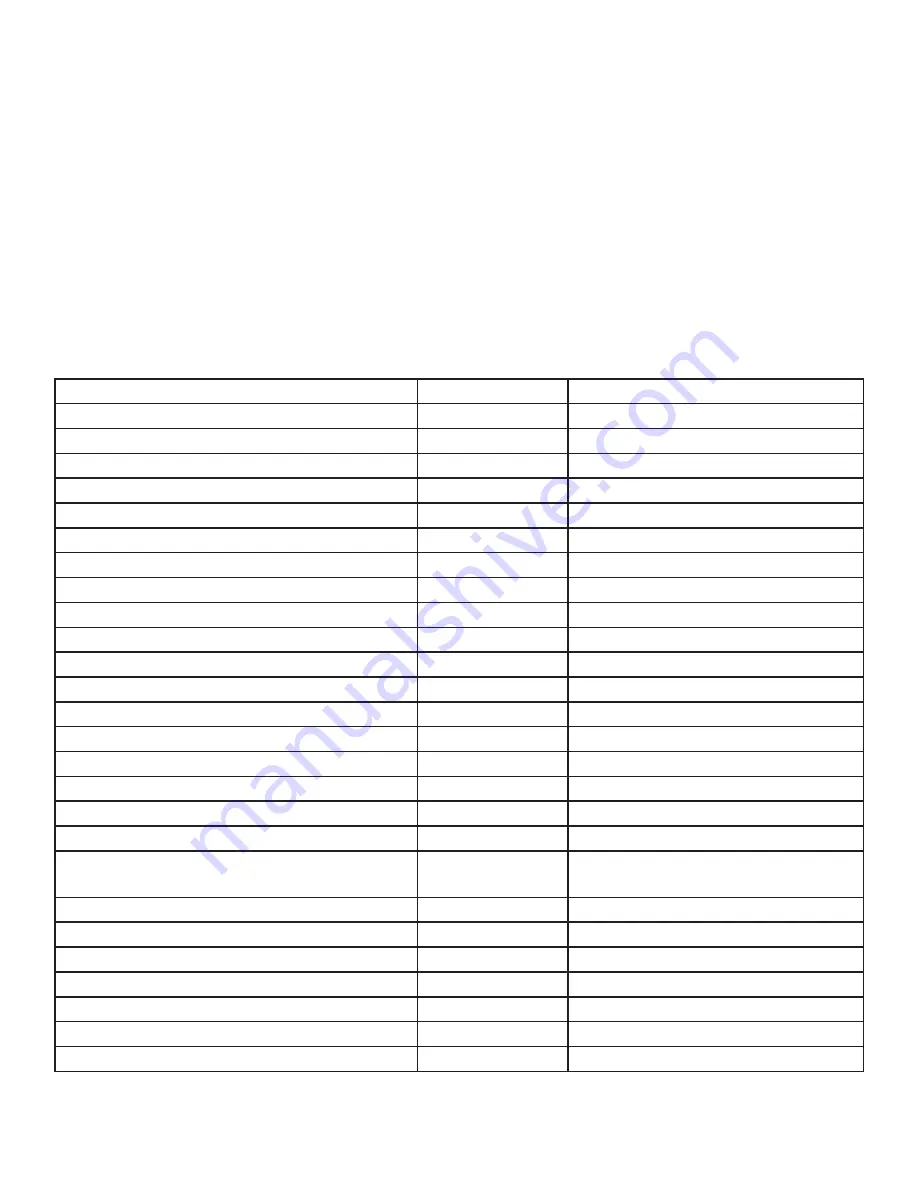

TECHNICAL DESCRIPTION

U/M

BD 26/27

Cleaning width

in/mm

26/660

Squeegee width

in/mm

33/835

Working capacity, up to

sq.ft./h/sqm/h

35,521/3300

Brushes diameter

in/mm

2 x 14/345

Brushes rpm

rpm

190

Pressure on the brushes

lbs./kg

132/60 max

Brushes motor

A/W

27/650

Traction motor

A/W

25/600

Vacuum motor

A/W

24/580

Vacuum Motor

in/mbar

64/160

Type of drive

autom.

Movement speed

mph/km/h

3.1/5

Maximum gradient

%

10

Solution tank

gallon/l

26/100

Recovery tank

gallon/l

27/105

Machine length

in/mm

60/1520

Machine height

in/mm

52/1320

Machine width (without squeegee)

in/mm

29/730

Weight of the machine (empty and without

batteries )

lbs./kg

525/238

Capacity of the batteries

Ah 5

240

Weight of the batteries

lbs./kg

441/200

Compartment of the batteries

in/mm

16x20.5x15/415x520x385

Acoustic pressure level

dB (A)

< 70

Class

III

Protection level

IP

23

Voltage

V

24