15

In order to avoid serious damages to the

suction motor, the machine is equipped with

a float that intervenes when the recovery tank

is full. When this happens, it is necessary to

empty the recovery tank. Hold the exhaust

hose of the machine. Take off the plug and

empty the recovery tank into appropriate

containers, according to the standard norms.

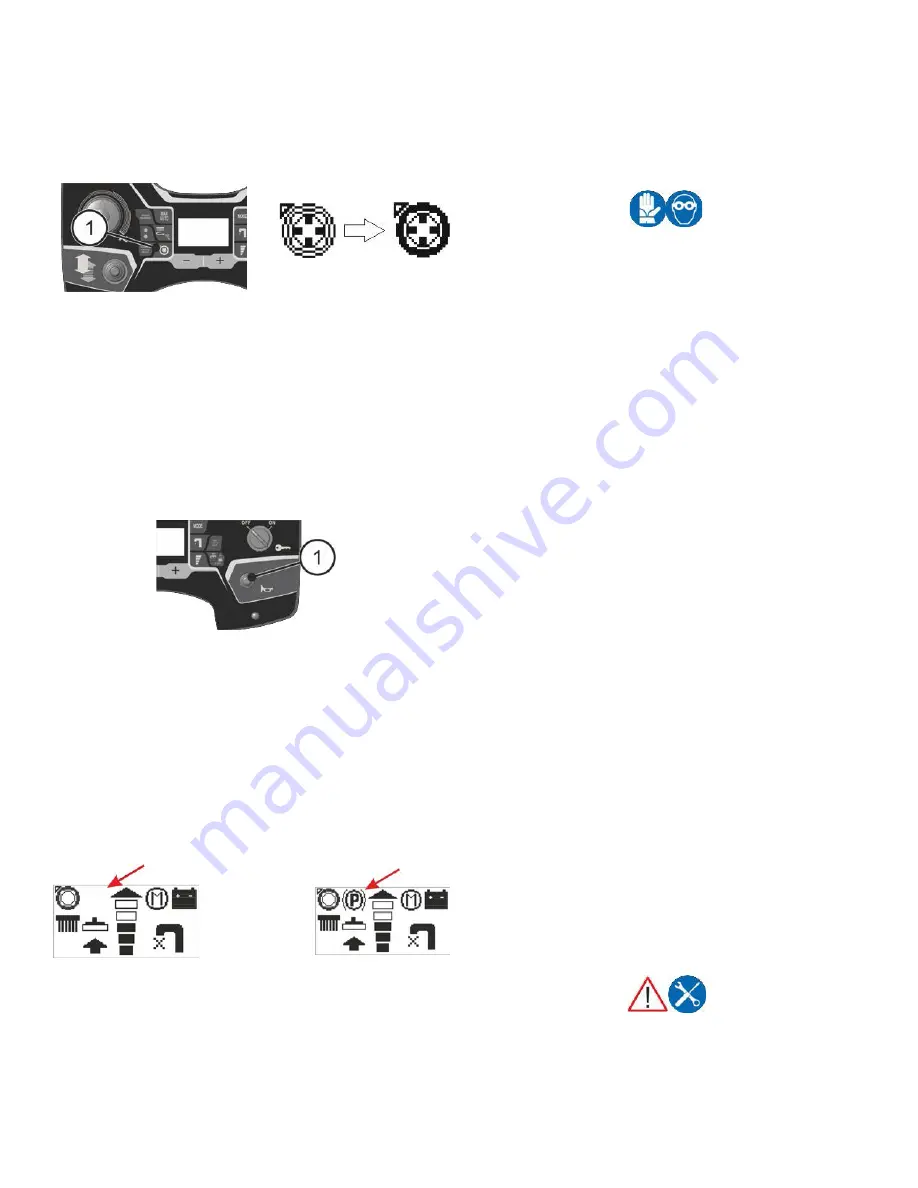

It is possible to start the silent mode of the

suction motor by pressing for a few seconds

the switch-on button (1) of the suction motor.

When the silent mode is on the symbol on the

display changes.

SILENT MODE SUCTION MOTOR

STAND-BY MODE

After 10 minutes of inactivity, if the machine is

on, it goes in stand-by mode and the display

turns off. To start again press any button on

the instrument board, the display will turn on

again and after a few seconds the machine

returns operative.

HORN

The machine is provided with a horn that can

be activated pressing button (1).

PARKING BRAKE

The machine is equipped with a parking brake

on the traction motor wheel that operates at

the complete release of the pedal or when the

machine is without batteries. In case of an

emergency or simply to stop the machine, it

is sufficient to release the pedal. The brake

remains applied until the pedal is pressed

again. When the batteries are connected and

when the key switch is positioned on 1, on the

display for the brake signal comes on.

BRUSHES MOTOR OVERLOAD PROTECTION

SYSTEM

When this happens, try to reduce the brushes

pressure (see under “ADJUSTMENT OF THE

BRUSHES PRESSURE”).

If the problem persists, contact the authorized

service center.

The machine is equipped with a protection

device of the brushes motor.

This device blocks the motor functioning in

order to protect it and indicates the overload

on the display with the message “ALARM 1”.

OVERFLOW SYSTEM

MACHINE STOP AFTER CLEANING

OPERATION

BREAK WASHING MODE

IN AUTOMATIC OR MANUAL WORKING

MODE:

1. At the end of the washing cycle, keeping the

button (1) pressed, the functioning of BREAK

WASHING is chosen.

2. When the mode is on, BREAK WASHING is

shown on the display.

This way, automatically, the brushes lift, the

solenoid valve shuts down and it is possible to

finish the drying operation for a total time of

about 15 seconds, afterwards the suction

stops.

NOTE

: all these phases are carried out with the

machine operating, so that the squeegee can

dry the interested cleaning area from the

“drying phase of the brushes” and furthermore

can dry the suction hose of its dirty water.

At any time it is possible to interrupt the

procedure BREAK WASHING by stopping the

drive.

During the BREAK WASHING, if the drive

pedal is released for more than 3 seconds the

machine will automatically switch to manual

mode (MAN).

The mode (BREAK WASHING) is specific

for the transfer at the end of the cleaning

operation.

Summary of Contents for BDSO 20/21

Page 21: ...21 TS120 S59 U...