11

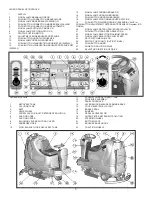

The bending is not uniform

Adjust the squeegee inclination rotating counter-

clockwise the wing nut (7) to increase the bending

in the central part, or clockwise to increase the

bending on the extremities.

Height adjustment

Once that the pressure and inclination of the

squeegee have been adjusted, it is necessary to

fix this optimum condition making touch slightly

the wheels onto the floor. Rotate counterclockwise

the registers (8) to lower the wheels or clockwise

to raise them. Both wheels must be adjusted in

the same measure.

ATTENTION:

Every type of floor requires a specific adjustment.

For example, concrete floors (where the friction

results to be high) need little pressure, while

smooth floors (ceramics) need higher pressure.

If the cleaning operations are made always on the

same type of floor, the adjustment can change

only in function of the rubber wear.

ADJUSTMENT HEIGHT SIDE RUBBERS

To adjust the side rubbers, it is necessary to act

upon the adjusting screws (1) and (2) after having

loosened the upper blocking nuts. Unscrewing,

the rubber lowers, while screwing down, the rub-

ber is lifted. The reason of the adjustment is to

obtain an uniform bending.

Having finished the adjustment, tighten the block-

ing nuts to fix the position.

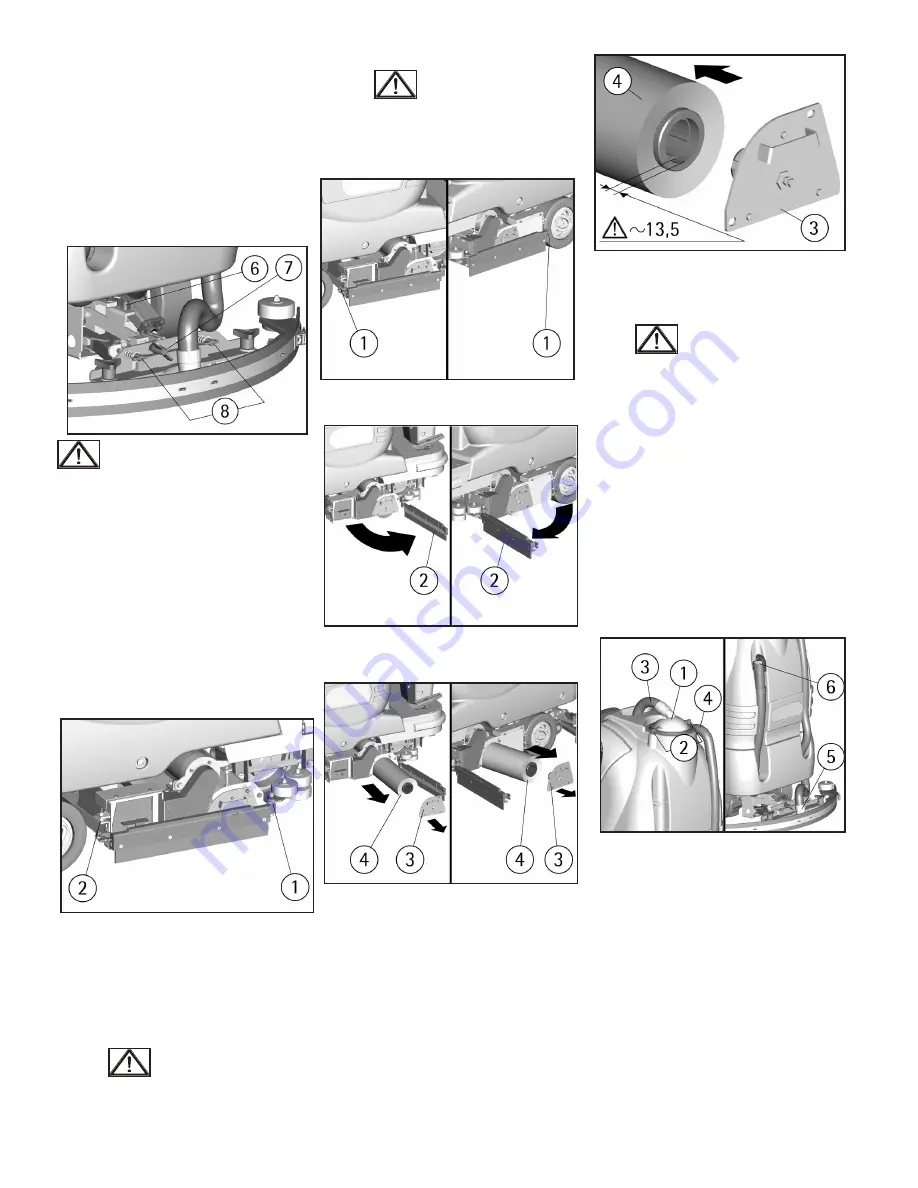

BRUSHES ASSEMBLY AND DISASSEMBLY

Normally, the machine is delivered with the

brushes assembled.

To assemble and disassemble the brushes on

both sides of the machine:

1. Make sure the machine is switched off and with

the brushes base in up position (lifted).

ATTENTION:

To carry out brushes assembly operations with

the electric supply on, may cause damages to

hands.

ATTENTION:

This operation must be carried out using gloves

to protect from contact with dangerous solutions.

2. Unblock the bar of the side rubber after having

released the knob (1).

3. Open the bar of the side rubber (2) as shown

in the figure.

4. Extract the support plate (3) of the brushes

pulling it outwards by holding its handle.

5. Extract the brush (4).

6. During the reassembly of the brush (4), insert

it into the brush base from the part where the

seat is deeper (about 1.5” (40mm)). The opposite

part with a depth of about .5” (13,5mm) has to

look towards the support plate.

7. Place the support plate (3) into its position, then

put back the bar of the side rubber (2) blocking it with

the knob (1).

ATTENTION:

The brushes must be inserted easily without using

tools in order not to damage or force them.

Use only brushes supplied with the machine or the

ones indicated in the paragraph “RECOMMENDED

BRUSHES”. The use of other brushes can compro-

mise the good washing result.

FLOOR CLEANING

RECOVERY TANK

Check that the cover of the suction filter (1) is cor-

rectly secured, after rotating the levers (2) and that

the suction motor hose (3) is correctly connected to

it.

Verify also that the squeegee hose couplings (4/5)

are correctly inserted into their seats and that the

exhaust hose plug (6) placed in the rear part of the

machine is well closed.

DETERGENT SOLUTION TANK

The capacity of the detergent solution tank is indi-

cated in the technical data.

Open the screw plug placed in the left part of the ma-

chine and fill the detergent solution tank with clean

water at a maximum temperature of 50°C (122°F).

Add the liquid detergent in the percentage and condi-

tions foreseen by the manufacturer. To avoid exces-

sive foam presence, which could cause problems to

the suction motor, use the minimum percentage of

detergent. Screw down the plug to close the tank.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...