12

ATTENTION:

Use always low foam detergent. To avoid foam

pres¬ence, before starting working operation,

introduce into the recovery tank a minimum

quantity of anti-foam product.

Never use pure acid.

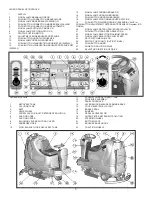

3SD SYSTEM SOLUTION SAVING SYSTEM

DISPENSER (OPTIONAL)

The system permits the predetermined dos-

ing of the detergent percentage which will be

mixed with the water of the solution tank.

The system consists of a dual hydraulic circuit,

one for the water and one for the detergent,

each one equipped with a suitable pump.

The detergent is contained in a tank with a ca-

pacity of 2 gallons (8 litres), placed in the front

part of the machine.

The tank is transparent, to enable the visual-

ization of the detergent level.

Pressing once the push button (A) on the in-

strument board, on the display (1) the indicator

shows the detergent percentage which is being

used.

Pressing the same push button in succes-

sion, six different possibilities of setting can be

selected and the display (1) visualizes always

the percentage.

The indication of the level corresponds to the

following detergent percentages in the water:

d0 = 0 %

d1 = 0,3 %

d2 = 0,6 %

d3 = 1,2 %

d4 = 2,4 %

d5 = 4,5 %

The last dosing adjustment set remains stored

by the system also with the machine stopped.

The dosing adjustment can be made only with

the brushes moving (during operation), so that

the dosing ratio cannot be modified acciden-

tally.

The water flow is adjusted through the 8-way

commutator (B): one OFF position and 7 op-

erating positions from a minimum of .3 gallon

(1,2 litres)/min to a maximum of 1 gallon (3,7

lit)res/min.

In OFF position both the water flow and its

relative detergent flow is interrupted.

NOTE: the detergent percentage in the water

is in any case always constant independently

from the level course of the water set.

The water flow, besides from being connected

to the set position through the commutator, is

also proportional to the machine speed (posi-

tion of the accelerator pedal).

In this way, having to reduce the speed near

curves or in presence of difficult areas, a

useless water waste is avoided and simulta-

neously the drying is improved, because the

squeegee picks up always the same solution

quantity.

When the commutator (B) is in OFF position,

an auxiliary water system can be activated,

that permits the traditional use of the machine

and therefore the filling of the solution tank with

water and detergent without using the system

and therefore without the use of the pumps.

In this case it is necessary to open and adjust

manually a solution valve (C) placed un-der the

machine. In this situation the push button (A)

handles the command of the solenoid valve in

manual function.

NOTE: at the end of each use of the machine

in the traditional mode (without dosing system),

to return to use the dosing system again, it

is necessary to close the solution valve (C),

otherwise the proportions water and detergent

are not anymore the predetermined ones.

NOTE: if the automatic dosing system is not

being used for a long time, it is possible that

the hoses of the detergent circuit are emptied

and therefore at the first use, the detergent

begins to come out onto the brushes with a

certain delay compared to the water outlet.

Through the solution valve (D) it is possible to

empty the detergent tank and to recover the

detergent.

STARTING OF THE MACHINE

A safety device avoids the machine’s movement if the

operator is not seated correctly on the guiding place.

To switch on the machine:

1. Sit on the guiding place.

2. Turn the key switch (24) clockwise to switch on the ma-

chine. Automatically, the machine gets ready in manual

(MAN) mode and in forward movement with the quick

speed (signal lamp 22).

3. Check the charge level of the batteries on the display

(1).

4. Pressing the push button (5) the functioning of BREAK

WASHING is chosen and the transfer operations of the

machine are carried out (see under paragraph “FOR-

WARD AND BACKWARD MOVEMENT"). When the

signal lamp (4) is on, then the machine is in BREAK

WASHING mode.

5. Pressing the push button (6) the automatic (AUTO)

functioning is chosen, while pressing the push button (3),

the functioning of the machine becomes manual (MAN).

A. When the signal lamp (7) is on, the machine is

functioning in automatic (AUTO) model and the machine

activates and deactivates all the working functions in an

automatic mode (see under paragraph “WORKING IN

AUTOMATIC MODE”).

B. When the signal lamp (2) is on, the machine is

functioning in manual (MAN) mode and it is possible to

choose if:

I. to carry out the only transfer of the machine without

activating or deactivating the working functions.

II. to activate separately only the controls relative to the

washing function with the brushes (see under paragraph

“WORKING IN MANUAL MODE”).

III. to activate separately only the controls relative to the

drying function with the squeegee (see under paragraph

“WORKING IN MANUAL MODE”).

ATTENTION:

In manual mode every function of the machine has to be

activated or deactivated manually.

FORWARD AND BACKWARD MOVEMENT

It is recommended to carry out always the mere transfer

of the machine in mode (BREAK WASHING).

To proceed to activate the movement of the machine:

1. Sit on the guiding place.

2. Turn the key switch (24) clockwise to switch on the

machine.

3. Check the charge level of the batteries on the display

(1).

4. Pressing the push button (5) the functioning of BREAK

WASHING is chosen to carry out the mere transfer of the

machine. In fact, in this mode the washing functions of

the machine are not working and only the traction system

functions. When the signal lamp (4) is on, then the ma-

chine is in BREAK WASHING mode.

5. Check through the signal lamp (15) that the parking

brake is not inserted and eventually release it (see under

paragraph EMERGENCY-PARKING BRAKE”).

6. Positioning the selector (28) forward, the forward

drive is chosen, while positioning it back, the rear drive is

chosen.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...