13

7. Press the accelerator pedal placed on the right

part of the platform to start the machine.

8. Adjust the movement speed in forward press-

ing every time the push button (21) to choose the

slow one (at the maximum 2.2 mph (3,6 km/h) is

reached) or the fast one (at the maximum 3.1 mph

(5 km/h) is reached). The signal lamp (22) indicates

that the fast drive is selected, while signal lamp

(23) indicates that the slow drive is selected.

9. In backward movement, when the machine is

moving, an intermittent warning device is activated.

HORN

The machine is equipped with a horn which is

activated pressing the push button (1).

WORKING BRAKE

To stop the machine during normal working situ-

ations, it is sufficient to release the accelerator

pedal, because the machine has got an electronic

brake system. To restart, press again the

accelerator pedal.

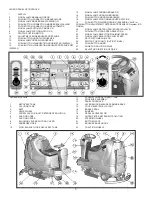

EMERGENCY-PARKING BRAKE

In case of an emergency press the pedal of the

emergency and parking brake (1) placed on

the left side.

To insert the parking brake press the brake pedal

(1) and simultaneously move downwards the lever

(2) placed on the left side of the steering column.

On the instrument board the signal lamp (15)

comes on which signals that the parking brake is

inserted.

To release the parking brake press the brake

pedal (1).

AUTOMATIC SQUEEGEE LIFTING WHEN

GOING BACKWARDS

Selecting the backwards movement the

squeegee is brought automatically to the upper

position. It will then lower again in the following

forward movement.

This happens both in automatic as in manual

mode in order to protect the integrity of the

squeegee.

WORKING IN AUTOMATIC MODE

The automatic operation is useful to simplify the

operator’s work.

1. Activate the machine (see under paragraph

“STARTING OF THE MACHINE”).

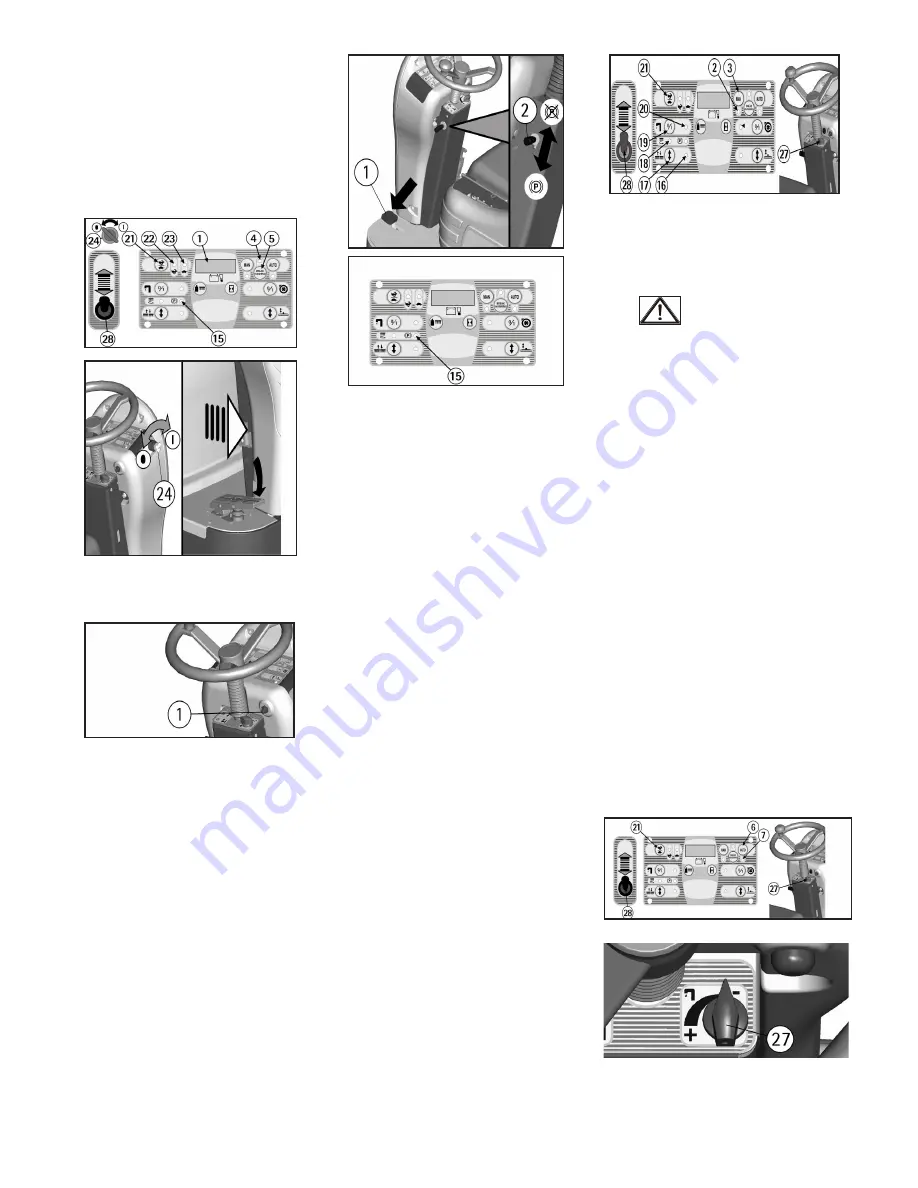

2. Pressing the push button (6) the automatic

(AUTO) functioning is chosen. When the signal

lamp (7) is on, then the machine is functioning

in automatic (AUTO) mode.

3. Check that the knob of the solution valve (27)

is in the position of optimum flow, depending on

the type of floor and the type of dirt (see under

the paragraph “FLOW ADJUSTMENT OF THE

DETERGENT SOLUTION”).

4. Position the selector (28) forward to choose

the forward drive.

5. Adjust the movement speed in forward with

the push button (21) (see under paragraph

"FORWARD AND BACKWARD MOVEMENT").

6. Pressing the accelerator pedal, the machine

begins to proceed and in automatic mode all

the working functions are activated. In fact,

automatically both the brushes base as the

squeegee go down, the brushes begin to turn,

the solenoid valve opens to permit the deter-

gent solution to flow down onto the brushes

and the suction system is activated to recover

the dirty water from the floor.

Positioning backwards the selector (28) to

choose the rear drive and pressing the accel-

erator pedal the rear drive starts, the squeegee

lifts automatically and will then return to lower

itself during the next for-ward movement.

If the accelerator pedal is released for more

than 3 seconds, automatically all the functions

are being switched off and both the brushes

base as the squeegee are being lifted.

Pressing again the pedal, the machine starts to

move again and in automatic mode all the

working functions are reactivated.

WORKING IN MANUAL MODE

The manual model is useful when, in special cases,

it is necessary to carry out separately only the wash-

ing with the brushes or only the drying of the floor.

ATTENTION:

The washing and drying functions, when they

are not carried out simultaneously, represent an

improper use of the machine (see under paragraph

“GENERAL RULES OF SECURITY”). If they are

carried out separately, it is necessary to forbid the

working areas to the passage of non-authorized

personnel and to signal the areas of moist floors

with suitable signs.

1. Activate the machine (see under paragraph

“STARTING OF THE MACHINE”).

2. Pressing the push button (3) the functioning of

manual (MAN) mode is chosen. When the signal

lamp (2) is on, then the machine is functioning in

manual (MAN) mode.

TO CARRY OUT THE WASHING WITH ONLY THE

BRUSHES

:

1. Check that the knob of the solution valve (27) is in

the position of optimum flow, depending on the type

of floor and the type of dirt (see under the paragraph

“FLOW ADJUSTMENT OF THE DETERGENT

SOLUTION”).

2. Press the push button (17) of up/down of the

brushes base to lower the brushes. Once that it is

lowered, the brushes begin to turn. The signal lamp

(16) indicates that the brushes base is lowering or

lifting, while the signal lamp (18) signals that the

brushes are turning.

3. Press the switch (19) to open the solenoid valve

and permit the detergent solution to lower onto

the brushes. The signal lamp (20) will come on, to

indicate that the solenoid valve is open.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...