14

TO CARRY OUT THE FUNCTION OF ONLY

DRYING:

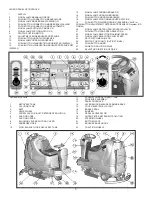

1. Press the push button (11) of up/down squee-

gee to lower the squeegee. The signal lamp (12)

indicates that the squeegee is lowering or lifting.

2. Press the switch (9) of the suction motor to

start the suction system. The signal lamp (8)

indicates that the machine is drying.

Position the selector (28) forward to choose the

forward drive.

Adjust the movement speed in forward with the

push button (21) (see under paragraph "FOR-

WARD AND BACKWARD MOVEMENT”).

Pressing the accelerator pedal, the machine

begins to proceed forward and to work according

to the set functions.

ATTENTION:

In manual mode every function of the machine

has to be activated or deactivated manually.

WORKING ADJUSTMENTS

Both in automatic as in manual mode, during the

first metres check:

1. that the squeegee adjustment guarantees a

perfect drying result (see under paragraph “AD-

JUSTMENT OF THE SQUEEGEE”).

2. that the adjustment of the detergent solution

flow is sufficient to wet the floor uniformly

avoiding the leakage of detergent from the

splash guards (see under paragraph “FLOW AD-

JUSTMENT OF THE DETERGENT SOLUTION”).

3. that the brushes pressure permits an efficient

washing action in function of the dirt and the

speed (see under paragraph “ADJUSTMENT OF

THE BRUSHES PRES-SURE”).

FLOW ADJUSTMENT OF THE DETERGENT

SOLUTION

To adjust the detergent solution quantity that

flows down onto the brushes it is necessary to act

upon the solution valve knob (27) placed on the

right of the steering column, rotating counterclock-

wise to increase it and clockwise to reduce it up

to close the flow.

ADJUSTMENT OF THE BRUSHES PRESSURE

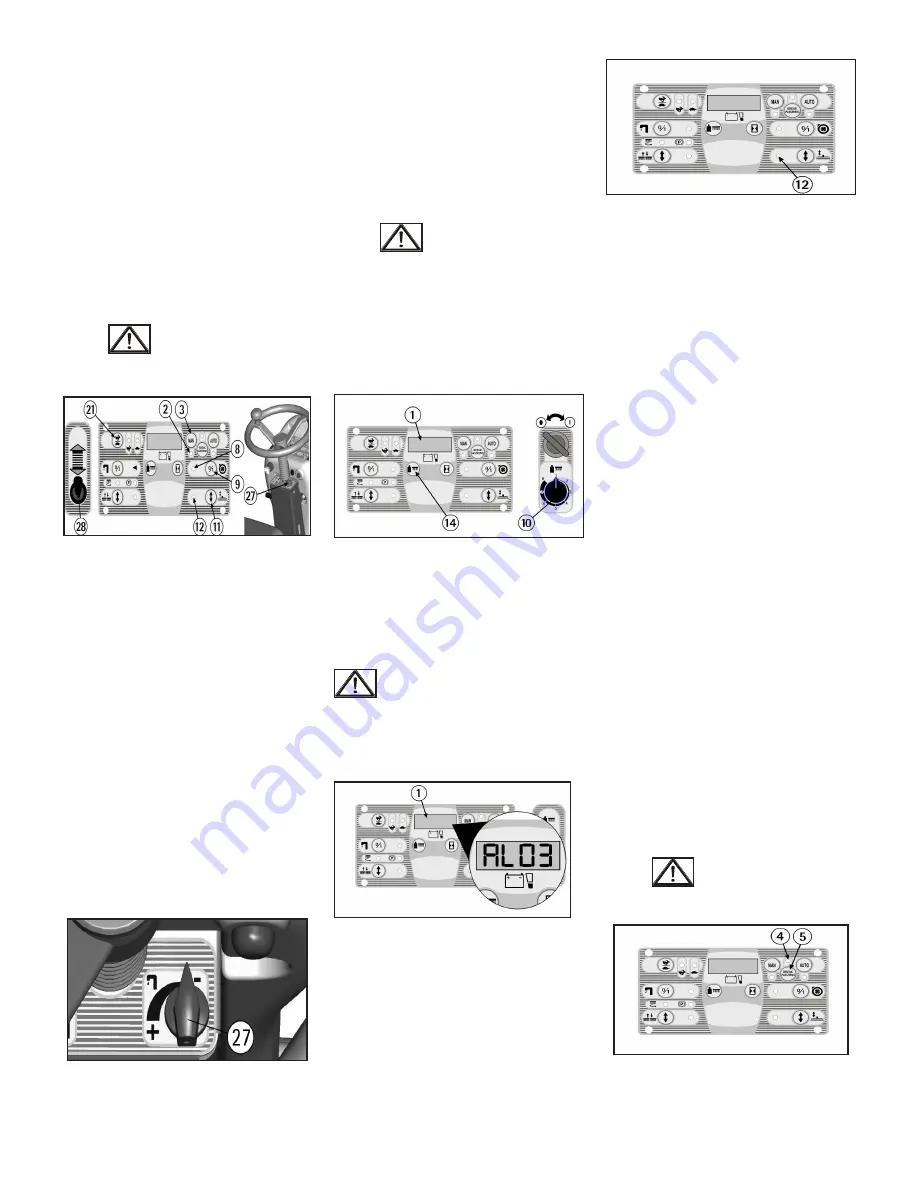

Both in automatic as in manual mode it is

possible through the knob (10) to adjust the

brushes pressure on the floor in eight established

levels. During the operation, we can visualize on

the display (1) the value in per percentage of the

electric absorption of the brushes motor by press-

ing the button (14).

The adjustment in this mode is done both in auto-

matic and manual operation.

ATTENTION:

In order not to overload the brushes motor, it is

convenient to reduce the brushes pressure going

from smooth floors to rough ones (ex. concrete).

The presence on the display (1) of a blinking

warning from P2 to P8 indicates that the pressure

level set determines an overload of the brushes

motor. It is therefore necessary to reduce the

pressure up to the level where the blinking

warning stops.

ELECTRIC PROTECTION

The machine is equipped with an electronic

system of protection for all components that carry

out functions of power or control. This device

blocks the defective component and indicates

on the display (1) the corresponding alarm from

”AL01” to “AL20”.

ATTENTION:

To restore the functioning of the component, turn

off and on again the machine acting upon the key

switch. If the problem persists, please contact the

authorized technical assistance.

OVERFLOW DEVICE

In order to avoid serious damages to the suction

motor, the machine is equipped with a

mechanical float that intervenes when the

recovery tank is full, closing the air flow of the

suction. The machines equipped with electric

float (optional), the switching off of the suction

motor and its signal lamp (12) happens in auto-

matic mode.

When this happens, it is necessary to empty the

recovery tank (see under paragraph “RECOVERY

TANK EMPTYING AND CLEANING”).

STOP OF THE MACHINE AFTER CLEANING

OPERATION

IN AUTOMATIC OR MANUAL WORKING

MODE:

1. A the end of the washing cycle, pressing

the push button (5), the functioning of BREAK

WASHING is chosen. When the signal lamp (4) is

on, then the machine is in the functioning mode

BREAK WASHING. In this way automatically the

solenoid valve shuts down, the brushes are lifted

slightly (a few millimeters) continuing to turn for

about 10 seconds (drying phase of the brushes)

and the collection box drains the exceeding water

to the floor; then, the washing group lifts com-

pletely while the squeegee continues to remain in

working position with the suction motor on, after

5 seconds the squeegee lifts and when it reaches

the highest position, also the suction motor stops,

with a delay of another 5 seconds.

NOTE: all these phases are carried out with

the machine operating, so that the squeegee

can dry the interested cleaning area from the

“drying phase of the brushes” and further-

more can dry the suction hose of its dirty wa-

ter. At any time it is possible to interrupt the

proce-dure BREAK WASHING by stopping the

drive.

2. During the phase of BREAK WASHING, when

the accelerator pedal is released for more than 3

seconds, the squeegee raises itself and the

suction switches off automati-cally.

3. After three seconds, the accelerator can be

pressed again, if a machine's transfer has to be

made (you can anyway make the transfer even if

the pedal is not lifted once that 20 seconds have

passed).

4. Turn the switch key counterclockwise to switch

off the machine.

5. Insert the parking brake (see under paragraph

“EMERGENCY-PARKING BRAKE”).

ATTENTION:

The mode (BREAK WASHING) is specific for the

transfer at the end of the cleaning operation.

Starting again the cleaning operation:

A. by pressing the push button (6) the automatic

(AUTO) functioning is chosen to start working in

automatic mode.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...