18

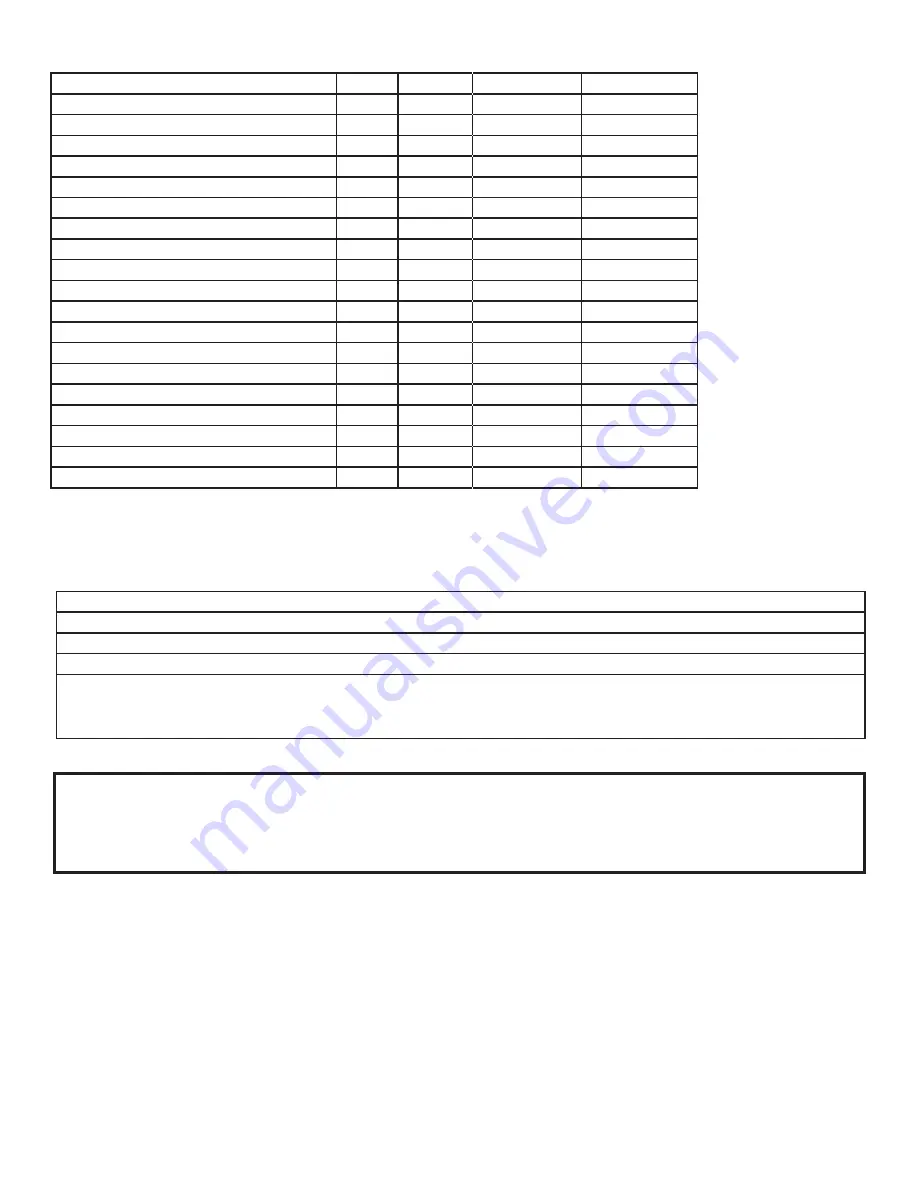

PROGRAMMED MAINTENANCE

INTERVENTION

DAILY

20 HOURS

200 HOURS

1000 HOURS

RECOVERY TANK CLEANING

•

SUCTION FILTER CLEANING

•

SOLUTION TANK FILTER CLEANING

•

BRUSHES CLEANING

•

BRUSHES DISASSEMBLY AND CLEANING

•

SQUEEGEE CLEANING

•

FRONT SQUEEGEE RUBBER REPLACEMENT

•

•

REAR SQUEEGEE RUBBER REPLACEMENT

•

•

SIDE RUBBERS REPLACEMENT

•

•

CHECK SQUEEGEE ADJUSTMENT

•

•

SQUEEGEE HOSE CLEANING

•

•

SOLUTION TANK CLEANING

•

•

CHECK BATTERIES ELECTROLYTE

•

•

CHECK OF THE BRAKE

•

TRACTION MOTOR CHECK

•

BRUSHES MOTOR CHECK

•

SUCTION MOTOR CHECK

•

CHECK BRUSHES BASE GROUP

•

SCREW TIGHTENING

•

* The hours refer to the ones indicated on the display (see under paragraph ”HOUR METER”).

RECOMMENDED BRUSHES

Brushes must be chosen depending on type of floor and dirt to be removed.

The employed material and the bristles diameter are the elements that distinguish different types of brushes.

BRISTLES THICKNESS

MATERIAL

CHARACTERISTICS

PPL (Polypropylene)

Good wear resistance. Maintains characteristics with hot water up to 50°C(122°F). It is not hygroscopic.

NYLON Excellent wear resistance, even with hot water. It is hygroscopic.

TYNEX Nylon bristles with grains of abrasive material. Use with caution in order not to mark the floor or ruin the polishing.

BRISTLES THICKNESS

Thicker bristles are more rigid and must be used on smooth floor or floor with small joints. On irregular floors with deep

joints or relieves, it is recommended to use softer bristles which penetrate more easily and deeper. Please be aware that when brush bristles are worn

out and therefore too small, they become rigid and unable to penetrate and clean deeper. This may also happen with thicker bristles creating brush

vibration.

MACHINE CODE

QUANTITY DESCRIPTION

USE

99775

BR 28 27

48906020

2

Cylindrical brush PPL 0,7 Ø (6”x26”)

Smooth floors with small joints and persistent dirt.

48906060

2

Cylindrical brush PPL 1 Ø (6”x26”)

Floors of resistant material and particularly dirty.

48906080

2

Cylindrical brush TYNEX Ø(6”x26”)

Floors of resistant material and particularly dirty.

48906100

2

Cylindrical brush PPL 0,3 Ø(6”x26”)

Smooth floors with small joints and persistent dirt.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...