4

SUMMARY

LONG-TERM BUYER

PROTECTION LIMITED WARRANTY

2

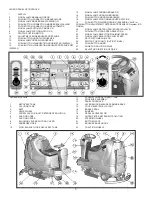

LEGEND PANEL OF CONTROLS

6

LEGEND MACHINE

6

TECHNICAL DESCRIPTION

7

INTRODUCTORY COMMENT

8

GENERAL RULES OF SECURITY

8

SYMBOLOGY

8

OPTIONAL ACCESSORIES

9

BEFORE USE

9

Handling of the packed machine

9

Unpacking of the machine

9

Access to the battery compartment

9

Battery

installation

9

Battery

recharger

10

Batteries

recharging

10

Batteries

disposal

10

Connection batteries' connector and

switching on of the machine

10

Batteries charge level indicator

10

Setting of the battery check card

10

Hour

meter

10

Squeegee

assembly 11

Adjustment of the squeegee

11

Adjustment height side rubbers

11

Brushes assembly and disassembly

11

FLOOR CLEANING

12

Recovery

tank 12

Detergent solution tank

12

3SD system Solution Saving System

Dispenser

(optional)

12

STARTING OF THE MACHINE

12

Forward and backward movement

13

Horn

13

Working

brake 13

Emergency-parking

brake

13

Automatism squeegee lifting when

going

backwards

13

Working in automatic mode

13

Working in manual mode

14

Working

adjustments 14

Flow adjustment of the detergent

solution 14

Adjustment of the brushes pressure

14

Electric

protection

14

Overflow device

14

STOP OF THE MACHINE AFTER CLEANING

OPERATION

15

DAILY MAINTENANCE

15

Recovery tank emptying and cleaning 15

Suction filter cleaning

15

Emptying and cleaning of the

collection

box 15

Brushes

cleaning

16

Squeegee

cleaning

16

WEEKLY MAINTENANCE

16

Rear squeegee rubber check

16

Squeegee hose cleaning

16

Cleaning of the solution tank

and of the outer filter

16

Check of the side rubbers

16

TWO-MONTHLY MAINTENANCE

16

Front squeegee rubber check

16

SIX-MONTHLY MAINTENANCE

16

Cleaning of the inner filter solution tank 16

Check of the brakes

17

TROUBLESHOOTING GUIDE

17

The suction motor does not work

17

The brushes motor does not work

17

The traction motor does not work

17

The water does not come down

onto the brushes or is insufficient

17

The machine does not clean properly 17

The squeegee does not dry perfectly

17

Excessive foam production

17

PROGRAMMED MAINTENANCE

19

RECOMMENDED BRUSHES

19

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...