5

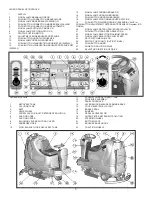

LEGEND PANEL OF CONTROLS

1. DISPLAY

2.

SIGNAL LAMP MANUAL MODE ON

3.

PUSH BUTTON CONNECTION MANUAL MODE

4.

SIGNAL LAMP MODE BREAK WASHING ON

5.

PUSH BUTTON CONNECTION MODE BREAK WASHING

6.

PUSH BUTTON CONNECTION MODE AUTOMATIC

7.

SIGNAL LAMP AUTOMATIC MODE ON

8.

SIGNAL LAMP SUCTION MOTOR ON

9.

SWITCH SUCTION MOTOR

10.

ADJUSTMENT KNOB BRUSHES PRESSURE

11.

PUSH BUTTON UP/DOWN SQUEEGEE

12.

SIGNAL LAMP UP/DOWN SQUEEGEE

13.

PUSH BUTTON VISUALIZATION HOUR METER (DISPLAY)

14.

PUSH BUTTON VISUALIZATION BRUSHES PRESSURE SET

(DISPLAY)

15.

SIGNAL LAMP PARKING BRAKE ON

16.

SIGNAL LAMP UP/DOWN BRUSHES

17.

PUSH BUTTON UP/DOWN BRUSHES

18.

SIGNAL LAMP STARTING BRUSHES ROTATION

19.

PUSH BUTTON WATER OPENING (SOLENOID VALVE) or

PUSH BUTTON ADJUSTMENT DETERGENT DOSAGE 3SD system (OP-

TIONAL)

20.

SIGNAL LAMP WATER OPEN (SOLENOID VALVE)

21.

PUSH BUTTON FOR SPEED SELECTION

22.

SIGNAL LAMP SELECTION MAXIMUM SPEED

23.

SIGNAL LAMP SELECTION SLOW SPEED

24.

KEY SWITCH MACHINE ON

25.

SWITCH FOR FRONT LIGHT (OPTIONAL)

26.

PUSH BUTTON HORN

27.

KNOB FOR SOLUTION VALVE

28.

SELECTOR DIRECTION OF DRIVE

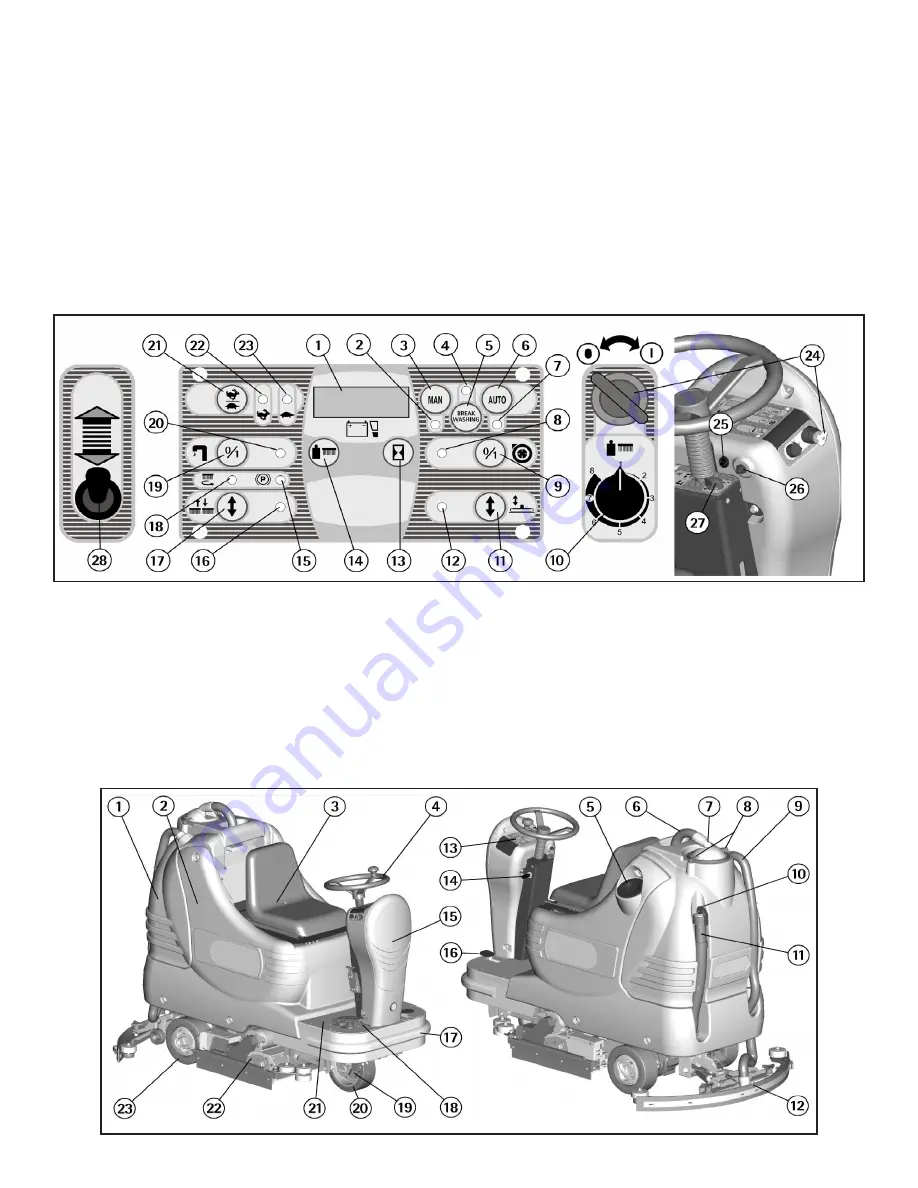

LEGEND MACHINE

1.

RECOVERY TANK

2.

SOLUTION TANK

3. SEAT

4.

DRIVE WHEEL

5.

SCREW CAP FOR INLET DETERGENT SOLUTION

6.

SUCTION HOSE

7.

SUCTION COVER

8.

BLOCKING LEVERS SUCTION COVER

9.

SQUEEGEE HOSE

10.

PLUG EXHAUST HOSE RECOVERY TANK

11.

EXHAUST HOSE RECOVERY TANK

12.

SQUEEGEE ASSEMBLY

13.

PANEL CONTROLS

14.

LEVER BLOCK/RELEASE PARKING BRAKE

15.

COVER ELECTRICAL LAYOUT

16.

BRAKE PEDAL

17. BUMPER

18.

PEDAL ACCELERATOR

19.

OUTER FILTER DETERGENT SOLUTION

20.

STEERING WHEEL

21.

BOTTOM PLATE

22.

BRUSHES BASE GROUP

23.

TRACTION WHEELS

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...