9

BEFORE USE

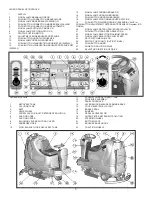

HANDLING OF THE PACKED MACHINE

The machine is supplied with suitable packing

foreseen for fork lift truck handling.

The total weight is 644 lbs.

Packing dimensions:

Base: 70” x 37” (178 cm x 93 cm)

Height: 55” (138 cm)

ATTENTION:

Do not place more than 2 packings on top of

each other.

UNPACKING OF THE MACHINE

1. Remove the external packing.

2. Unscrew the brackets (1+2) that secure the

machine to the pallet.

3. Move the machine backwards, as indicated in

the figure, avoiding heavy contacts to mechani-

cal parts.

4. Keep the pallet and the brackets for eventual

transport.

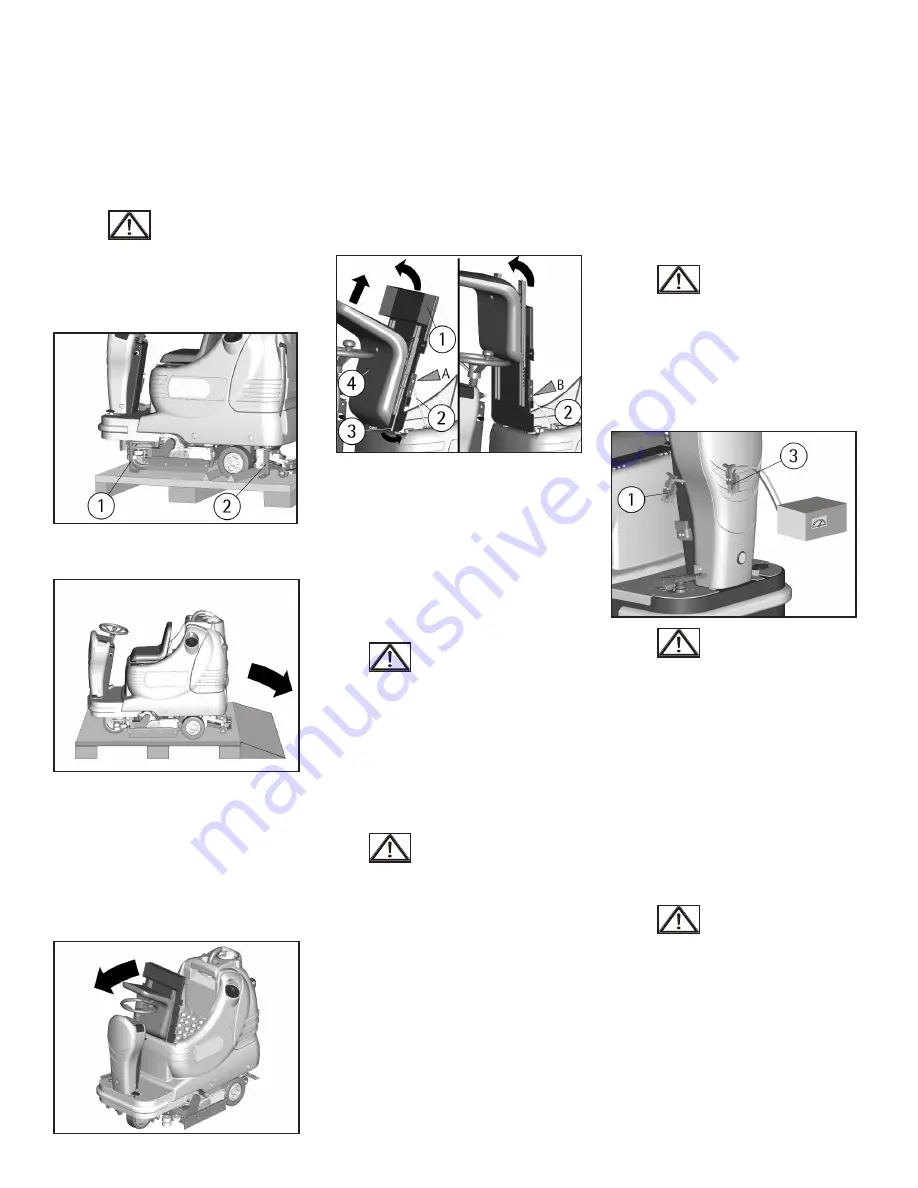

ACCESS TO THE BATTERY COMPARTMENT

1. Bring the machine on a level surface.

2. Rotate the seat platform forward and hook the

bar.

Having finished any intervention, to close the

battery compartment, reposition the seat plat-

form.

To install into the compartment a battery box, it is

necessary to:

1. Rotate the seat platform forward and hook the bar

(2) into position A.

2. Remove the holder (1) by unscrewing the two wing

nuts under the platform.

3. Pull outwards the releasing lever (3) of the seat

making slide the seat body (4) up to the highest posi-

tion.

4. Rotate further the platform in order to hook the bar

(2) into position B.

In this way it will be possible to handle the batteries

with suitable lifting equipment.

BATTERY INSTALLATION

The machine is equipped either with batteries in se-

rial connection or elements of DIN-type assembled

together and connected in series for a total of 24 Volt,

placed in its appropriate compartment under the seat

platform and must be handled using suitable lifting

equipment (due to weight, considering the type of bat-

teries chosen, and coupling system).

The batteries must be in accordance with CEI 21-5

Norms.

ATTENTION:

The machine and its battery check card foresee the

use of traditional lead batteries.

CHECK THE SETTING OF THE CHECK CARD (see

under paragraph "BATTERIES CHARGE LEVEL

INDICATOR").

In case of GEL batteries installation, it is necessary to

MODIFY THE SETTING of the electronic check card

(see under paragraph SETTING OF THE BATTERY

CHECK CARD”).

ATTENTION:

Strictly follow manufacturer/distributor indications for

the maintenance and recharge of the batteries. All

installation and maintenance operations

must be executed by specialized staff, using suitable

protection accessories.

For batteries installation it is necessary to reach the

battery compartment as indicated under paragraph

“ACCESS TO THE BATTERY COMPARTMENT”.

1. Place the batteries in its compartment.

2. Connect the terminals, respecting the polarities,

avoiding contact with other parts that could create

short circuit.

BATTERY RECHARGER

Make sure that the battery recharger is suitable

for the installed batteries both for their capacities

and type (lead/acid or GEL and equivalent).

In the plastic bag containing the use and mainte-

nance you will find the coupling connector for the

recharger. It must be assembled onto the cables

of your recharger, following the instructions given

by the manufacturer.

ATTENTION:

This operation must be carried out by qualified

staff. A wrong or faulty cable connection can

cause serious damages to persons or things.

BATTERIES RECHARGING

1. Plug the connector (3) of the battery recharger

into the battery connector (1).

2. Proceed for the recharging.

ATTENTION:

Never charge a GEL battery with a non suitable

recharger. Strictly follow the instructions supplied

by the batteries and recharger manufacturer.

In order not to cause permanent damages to the

batteries, it is necessary to avoid their complete

discharge, providing for the recharging within a

few minutes after that the batteries discharge

signal starts blinking.

NOTE: Never leave the batteries completely

discharged even if the machine is not used. In

case of traditional batteries, please check the

electrolyte level every 20 recharging cycles and

eventually top them up with distilled water. Never

leave the batteries discharged for more than two

weeks.

ATTENTION:

For the recharge of the batteries it is necessary

to follow strictly all the indications given by the

manufacturer/distributor. All the installation and

maintenance operations must be carried out by

qualified staff. Danger of gas exhalations and

emission of corrosive liquids. Fire danger: do not

approach with free flames.

Summary of Contents for BR 28/27

Page 2: ...2...

Page 3: ...3 NOTES...