19

TROUBLESHOOTING GUIDE

The checking of all the other foreseen machine

operations is left to the authorized technical

assistance.

SIGNALS ON THE DISPLAY

A001: Indication of the version of the electronic

check card (the last number indicates the revision of

the check card).

Pb24: Indication battery check card set for lead

batteries.

GE24: Indication battery check card set for gel

batteries.

---- (blinking): signal indicating the discharged

batteries.

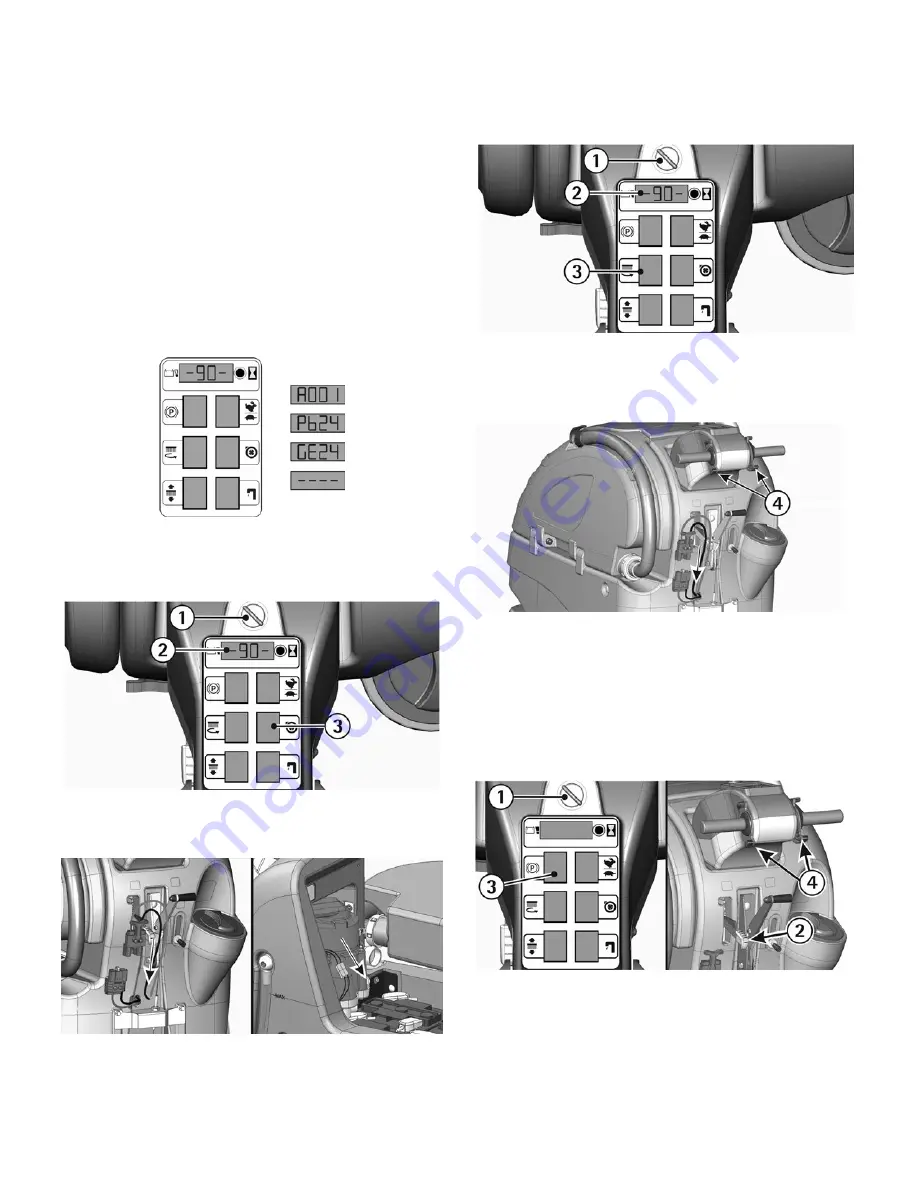

THE SUCTION MOTOR DOES NOT WORK

1. Verify that the key switch (1) is in the correct

position.

2. Check the charge level of the batteries (2).

3. Check that the battery connector is correctly

plugged in.

4. Verify that the switch (3) is on.

5. Check that the red connector of the suction motor

is correctly plugged in.

If the problem persists, please contact the

authorized technical assistance.

THE BASE MOTOR DOES NOT WORK

1. Verify that the key switch (1) is in the correct

position. Switch off and on again the machine.

2. Check the charge level of the batteries (2).

3. Check that the battery connector is correctly

plugged in.

4. Verify that the switch (3) is on.

5. Act upon the levers drive control (4).

If the problem persists, please contact the

authorized technical assistance.

THE TRACTION MOTOR DOES NOT WORK

1. Switch off and on again the machine (1).

2. Release the brake (2) until the signal lamp (3)

comes off.

3. Act upon the levers drive control (4).

If the problem persists, please contact the

authorized technical assistance.

Summary of Contents for OB 28/20

Page 3: ...3 NOTES...