20

INSUFFICIENT WATER ON THE BASE

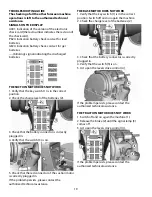

1. Check that the solution valve lever (1) is open.

2. Check the level of the liquid in the solution tank.

3. Check that the solution filter (2) is clean.

4. The machine is equipped with solenoid valve,

therefore act upon the levers drive control (3).

If the problem persists, please contact the

authorized technical assistance.

THE MACHINE DOES NOT CLEAN PROPERLY

1. Verify the presence of the PAD.

2. Verify that the PAD is intact.

3. To replace the pad, see under “PAD DISASSEMBLY”

and “PAD ASSEMBLY”.

4. The solution detergent is insufficient: open more

the solution valve.

5. Check that the liquid detergent is in the

recommended percentage.

6. Increase the base pressure (see at paragraph

"ADJUSTMENT OF THE BASE PRESSURE").

Contact the authorized technical assistance for

advice.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the squeegee rubbers are clean.

2. Check the adjustment of the height and

the inclination of the squeegee. (see section

“ADJUSTMENT OF THE SQUEEGEE” in “BEFORE USE”).

3. Check that the suction hose is correctly inserted in

the proper seat on the recovery tank.

4. Clean the suction filter.

5. Replace the rubbers if worn out.

6. Check that the suction motor switch is on.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been used.

Eventually add small quantities of anti foam liquid

into the recovery tank.

Please be aware that a bigger quantity of foam is

produced when the floor is not very dirty. In this case

please dilute more the detergent solution.

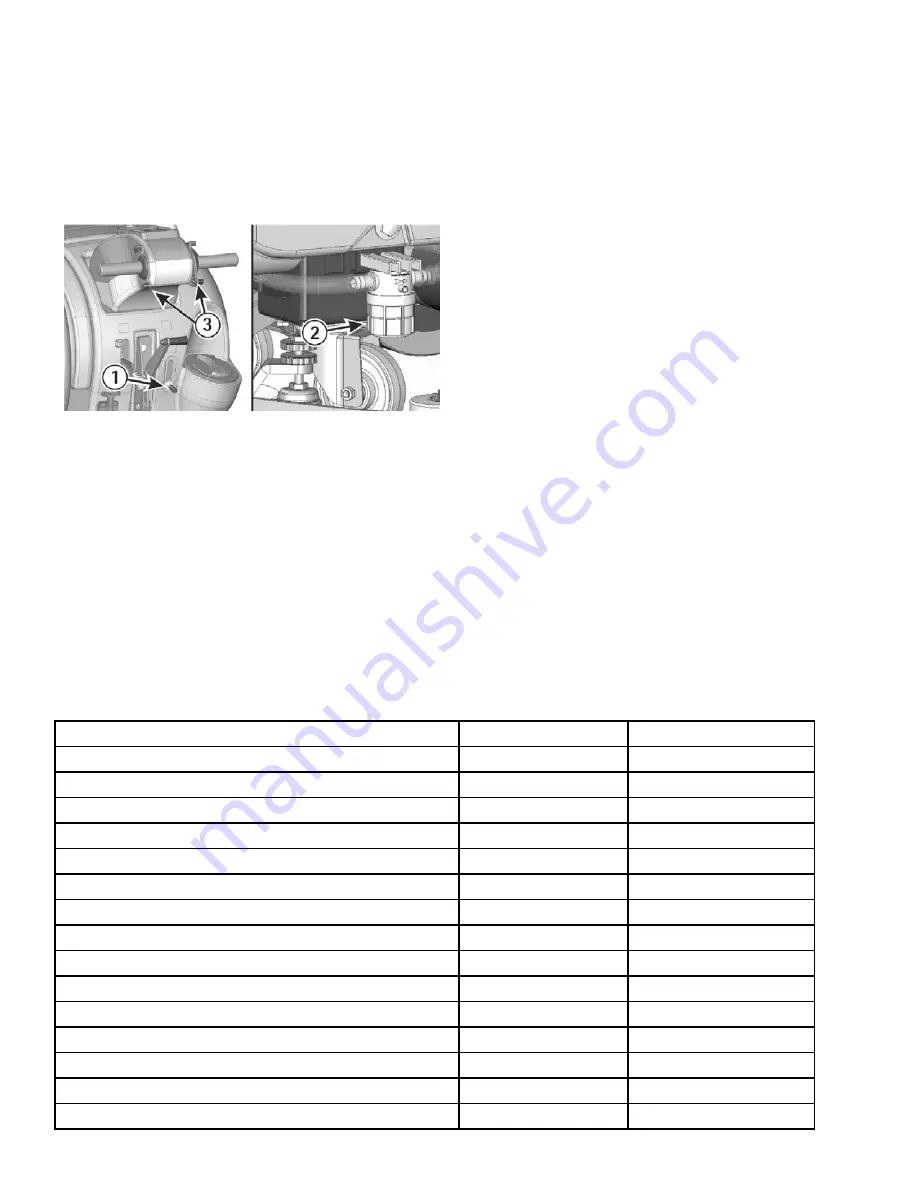

PROGRAMMED MAINTENANCE

INTERVENTION

DAILY

PERIODIC

RECOVERY TANK CLEANING

•

SUCTION FILTER CLEANING

•

SOLUTION FILTER CLEANING

•

PAD DISASSEMBLY AND CLEANING

•

SQUEEGEE CLEANING

•

FRONT SQUEEGEE RUBBER REPLACEMENT

•

REAR SQUEEGEE RUBBER REPLACEMENT

•

CHECK SQUEEGEE ADJUSTMENT

•

SQUEEGEE HOSE CLEANING

•

SOLUTION TANK CLEANING

•

CHECK BATTERIES ELECTROLYTE

•

TRACTION MOTOR CHECK

•

BASE MOTOR CHECK

•

SUCTION MOTOR CHECK

•

CHECK BASE GROUP

•

Summary of Contents for OB 28/20

Page 3: ...3 NOTES...