15

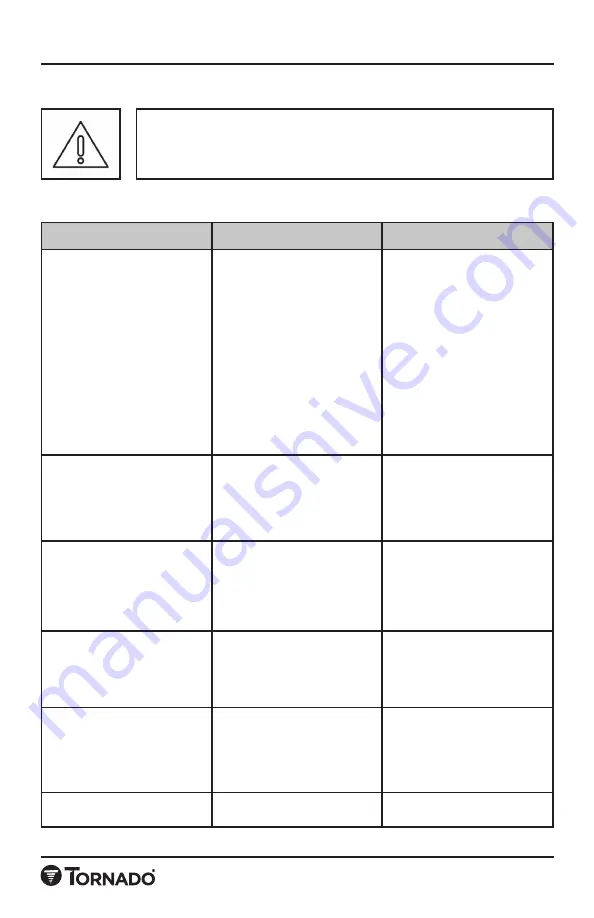

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Pump motor runs but

no spray through jets.

1. Clogged or faulty

solution filter.

2. Clogged or faulty quick

disconnect on housing.

3. Punctured pump

diaphragm.

4. Clogged jets

1. Check filter and remove lint

or other foreign material.

2. Depress plunger on

solution hose against

inside wall of solution tank.

If solution is flowing at this

point, the system is OK If

no solution flows, check

the quick disconnect for lint

and other foreign matter.

3. Replace with diaphragm

repair kit.

4. Clean jets on wand or tool.

Uneven spray from jet.

Spray weak or uneven.

1. Clogged strainer in

solution tank.

2. Clogged jet.

1. Unscrew strainer and

remove lint and any other

foreign material from

screen.

2. Remove and clean.

Leaking or stuck

solution valve.

1. Foreign material in valve.

2. Loose brass hex nut.

3. Valve or seals worn

1. Remove brass hex plug,

clean valve and replace.

2. Reseal hex and plug.

3. Replace worn parts with

solution valve repair kit.

Pump motor not working.

1. Loose wiring

2. Defective pump

pressure switch.

3. Motor burnout

1. Tighten wiring

2. Replace with new pressure

switch assembly.

3. Replace pump motor

Pump pressure low

1. Clogged screens on

strainer in solution tank.

2. Punctured pump

diaphragm.

1. Unscrew strainer remove

lint and any other foreign

material from screen.

2. Replace with diaphragm

repair kit.

Pump pressure varies.

1. Defective pump pressure

control switch.

1. Replace.

PUMP SYSTEM

The following checks may be performed by the operator.

Any other service or attempt to service by the operator

will void the warranty.

Summary of Contents for TE310-G15-U

Page 17: ...17 NOTES...