50

TORNADO

USE AND MAINTENANCE MANUAL

428000393

237

EN

UPRIGHT DISPLAY CABINETS

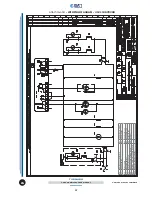

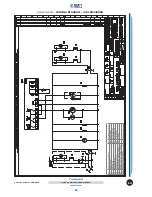

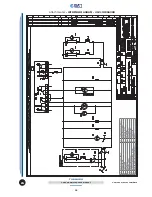

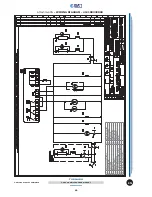

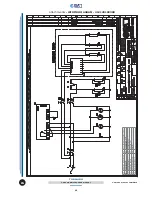

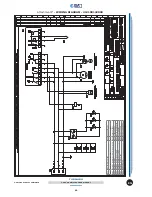

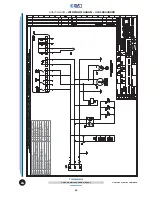

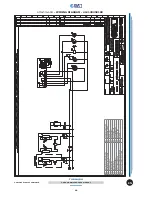

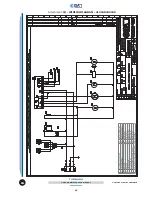

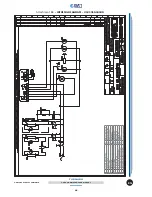

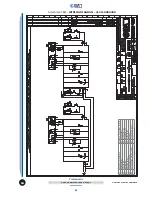

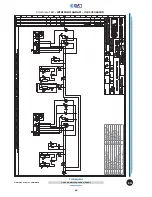

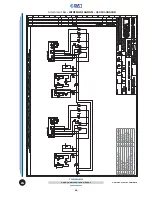

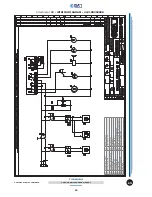

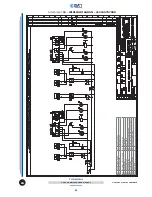

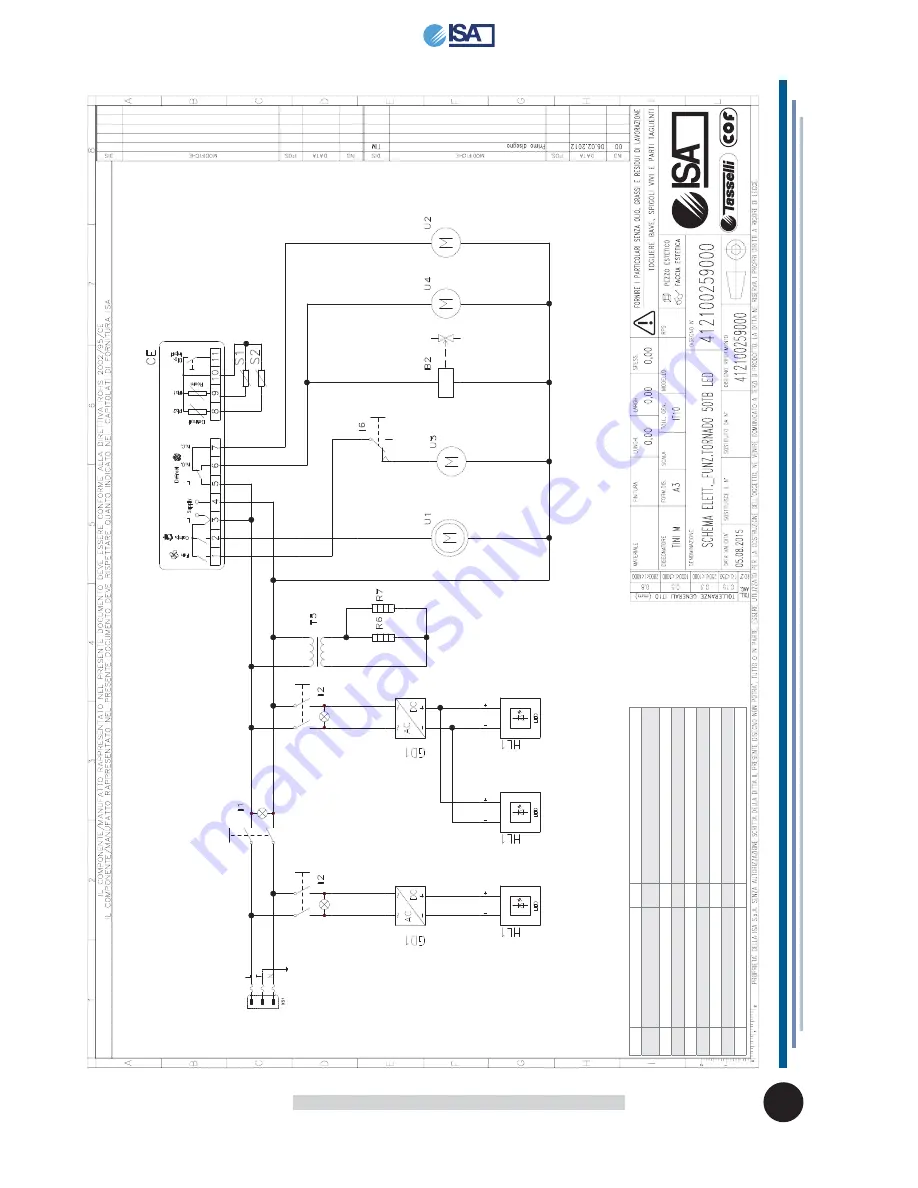

Attachment 15 - WIRING DIAGRAM - 412100259000

S1

Temper

ature probe

I1

Cabinet switch

S2

Defrosting probe

I2

Lighting switch

CE

Electronic control board

I6

Micro switch

U1

Compressor

T5

Tr

asformer

U2

Condenser fan

XS1

Plug power

U3

Ev

apor

ator fan

B2

Defrosting solenoid v

alv

e

U4

Cleaning fan

R6

Cold store door fr

ame heating resistor

GD1

Power supply LED

R7

Heating resistor glas

HL1

LED lamp