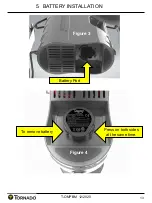

Prior to filling tank, remove battery from

unit and place away from wet area.

3. OPERATING INSTRUCTIONS

T-OMPBM 12/2020

9

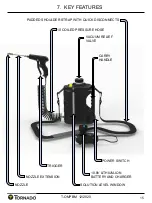

D. Operation

1. Remove cap from tank.

2. Pour the recommended amount of disinfectant into the ½ gallon tank and fill

about ¼ of the way fill with clean water. Replace cap and gently shake contents

to mix disinfectant with water. Remove cap and fill to full (F) line. Note that the

solution level can be viewed through the solution level window on either side of

the unit.

3. Ensure exterior of unit is dry prior to adding battery.

4. Install battery as outlined in section C.

5.

Turn switch to the ON position. You will hear the pump come on to build

pressure for spraying. Pull trigger on wand until uniform spray is discharged

from end of wand and to assist in the self priming feature.

6.

Pump will come on each time trigger is pulled and will run shortly after release to

keep pressure on the system. This will repeat during use.

Read and understand the requirements of the

disinfectant used. Dwell time, or the amount of time a

solution must remain on a surface, should be known for

maximum effectivity. Do not oversaturate.

7.

To apply, use a natural up and down or side to side motion ensuring complete

coverage by overlapping.

8.

Over a period of approximately 5 minutes of non

-use with the unit ON, pressure

may drop enough to “bump” the pump back on for a split second. This is to

serve as a reminder that the unit is still ON and should be turned off if use is not

intended to keep the battery from draining.

9.

Allow disinfectant to remain on the surface for the required amount of time

based on manufacturer’s recommendations. Wipe with clean, dry rag if required

following disinfection.

When the product is brand new and/or has not been

used for an extended period, it could take up to 30

seconds for fluid to reach the end of the wand.

Continue pulling trigger at startup until a strong flow of

mist is observed exiting the wand.