10

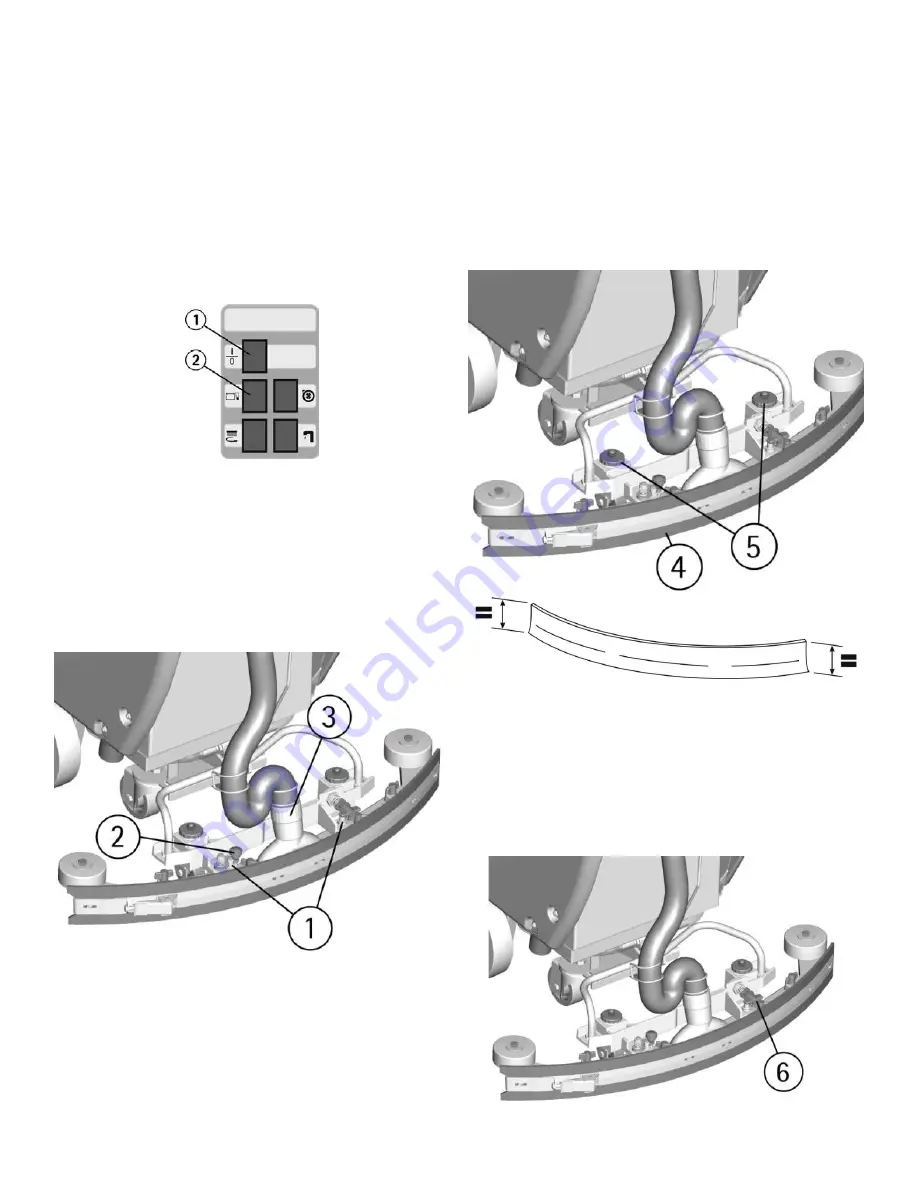

SQUEEGEE ASSEMBLY

With the squeegee support lowered, slide the

two stud bolts (1) placed on the upper part of

the squeegee inside the slots on the support.

Block the squeegee by rotating the lever (2)

clockwise. Insert the squeegee hose (3) into its

coupling, respecting its position as indicated in

the figure.

ADJUSTMENT OF THE SQUEEGEE HEIGHT

The squeegee must be adjusted in height

depending on the rubber wear. In order

to guarantee a perfect drying during the

operation, the lower blade of the rear squeegee

rubber (4) must work slightly bent backwards

(operator side) in a uniformed way in all its

length.

Acting counterclockwise it is possible to

decrease the rubber bending. A label placed

near the two registers (5) indicates rotation

sense to increase or reduce the height.

Note

:

The wheels of the squeegee support must be

adjusted through the registers (5) at the same

height so that the squeegee works parallel to

the floor.

ADJUSTMENT OF THE SQUEEGEE

INCLINATION

In case of need, to increase the rubber bending

in the central part, it is necessary to tilt the

squeegee rotating counterclockwise the

register (6). To increase the rubber bending on

the squeegee extremities, rotate the register

clockwise.

Acting clockwise upon the two registers (5) it is

possible to increase the bending of the rubber.

BATTERIES CHARGE LEVEL INDICATOR

When switching on, the signal lamp of the

battery charge level (2) will come on. When

the signal lamp is in green color it means that

the battery charge level is sufficient for the

functioning of the machine. If the signal lamp

is in red color it means that the battery charge

level is insufficient for the functioning of the

machine and it is necessary to recharge

the batteries (see under "BATTERIES

CHARGING”).

Summary of Contents for TS120-S53-U

Page 20: ...20...