5

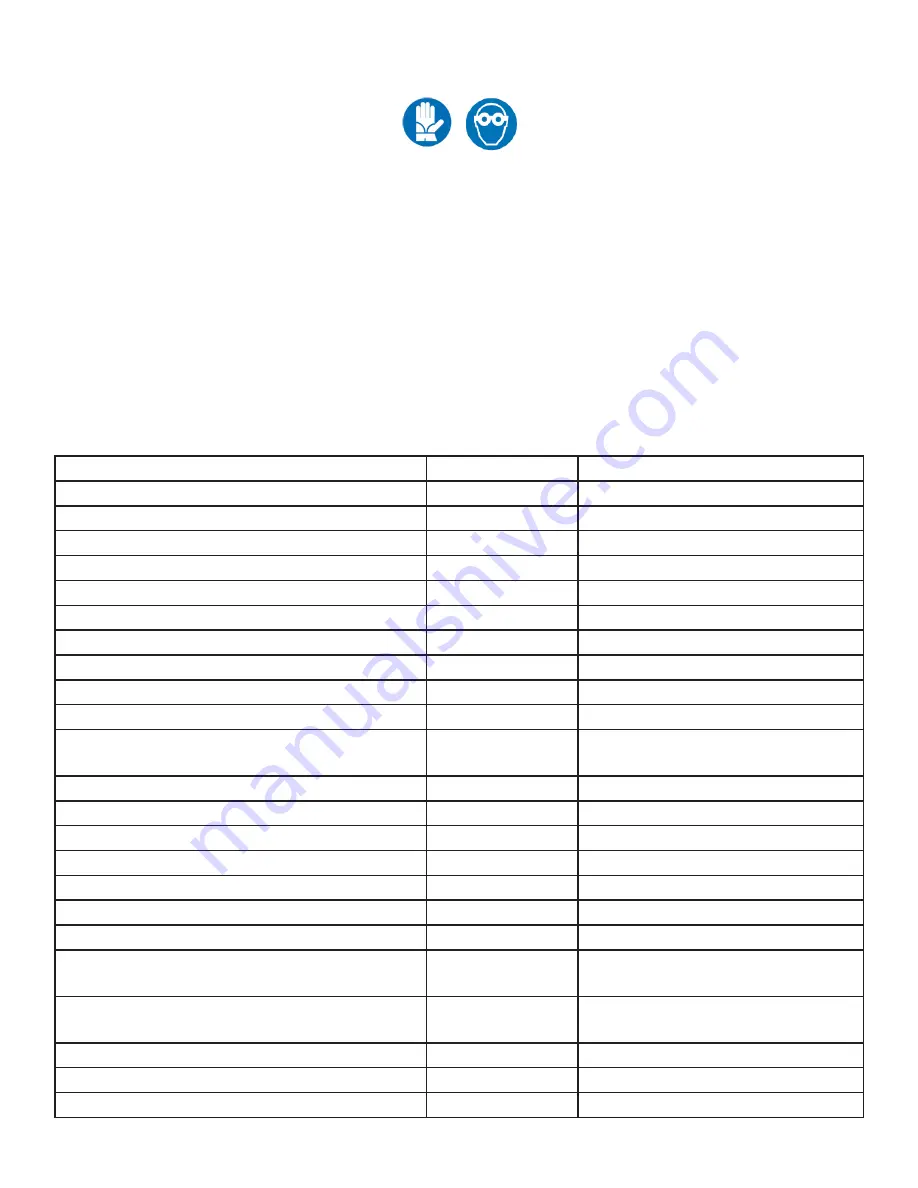

TECHNICAL DESCRIPTION

U/M

T120-S53-U

Cleaning width

mm/in

508/20

Squeegee width

mm/in

770/30

Working capacity

sqm/h/sqft/h

2000/21,528

Brush diameter

mm/in

508/20

Brush rpm

rpm

155

Pressure on the brush

kg/lbs

30/66 max

Brush motor

W/A

450/18.8

Type of drive

automatic

Maximum gradient

%

2

Suction motor

W/A

450/18.8

Suction vacuum

mbar\in water

lift

120/48

Solution tank

l/gal

40/11

Recovery tank

l/gal

45/12

Machine length

mm/in

1195/47

Machine height

mm/in

1053/42

Machine width (without squeegee)

mm/in

530/21

Weight of the batteries

kg/lbs

74/163

Compartment of the batteries

mm/in

342x340x295 /13.5x13.4x11.6

Weight of the machine (empty and without

batteries)

kg/lbs

76/168

Acoustic pressure level (in conformity with

IEC 704/1)

dB(A)

<70

Class

III

Protection level

IP

X3

Tension

V

24

− Do not take off the

protections which require the

use of tools for their removal.

− Do not wash the machine

with direct water, jets or with

high water pressure nor with

corrosive material.

− Every 200 working hours

have a machine check by an

authorized service department.

− Before using the machine,

check that all panels and

coverings are in their position

as indicated in this use and

maintenance catalogue.

− Do not place any metallic

tools onto the batteries. Risk

of short circuit!

− It is compulsory to hand

over exhaust batteries,

classified as dangerous waste,

to an authorized institution

according to the current laws.

GENERAL RULES OF THE

BATTERIES

At any intervention on the

batteries, use suitable acid-

proof gloves and glasses.

− Do not smoke near the

batteries and do not approach

them with free flames.

− Check that a fire-

extinguisher is available on

site.

− Be very careful in case of

leakages or liquid outlets

because corrosive.

Summary of Contents for TS120-S53-U

Page 20: ...20...