9

Strictly follow manufacturer/distributor

indications for the maintenance and daily

recharge of the batteries. All installation and

maintenance operations must be executed

by specialized staff, using suitable protection

accessories.

BATTERY RECHARGER

Be sure that the battery recharger is suitable

for the installed batteries both for their

capacities and type (lead/acid or GEL and

equivalent).

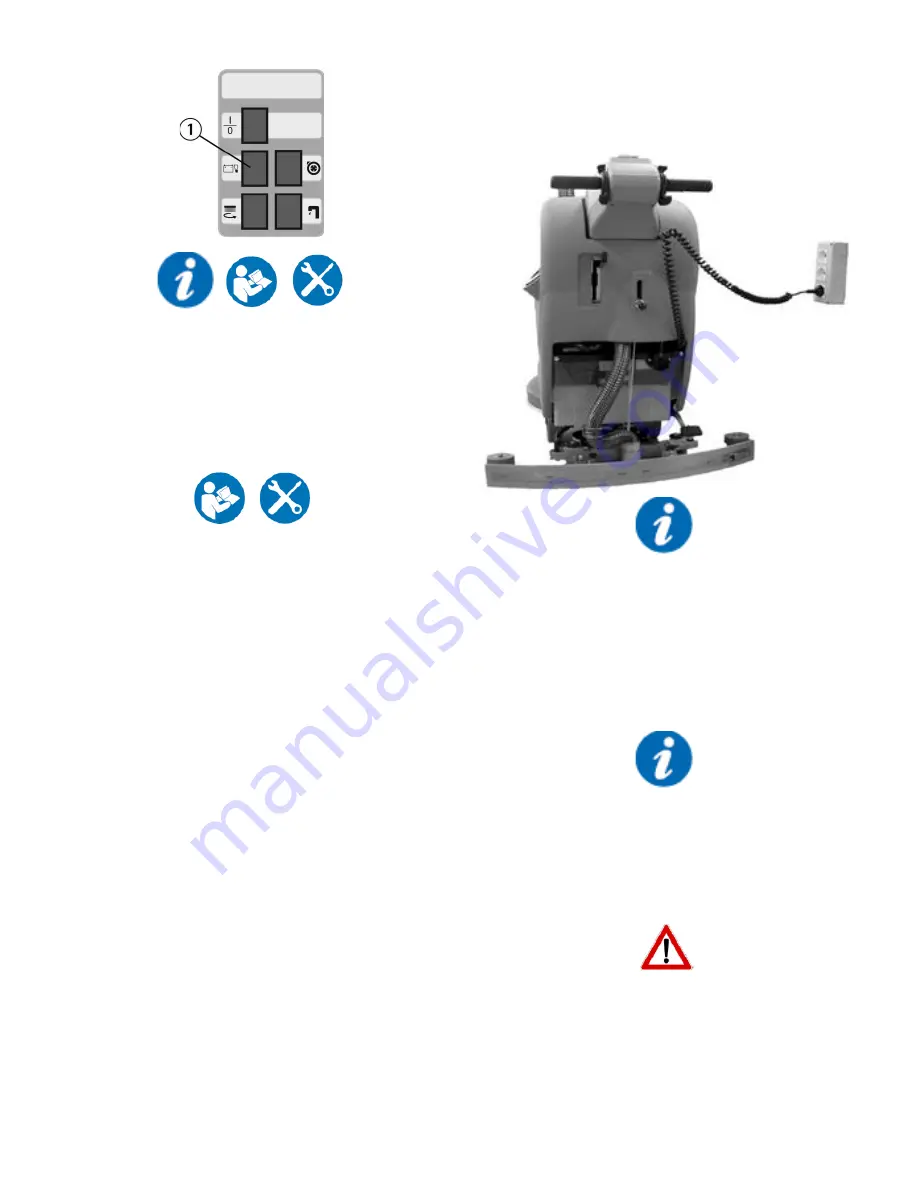

ON-BOARD BATTERY RECHARGER

The machine is equipped with the on-

board battery recharger. Please refer to the

manufactures instructions on the use of the

charger. The battery recharger is connected

directly to the battery poles. During the

recharging operations a device is activated

which does not permit the machine's

functioning. The main cable of the battery

recharger has a maximum length of two meters

and must be connected to a single-phase

socket type CEE 7/7.

BATTERIES RECHARGING

Bring the machine on a leveled surface near to

a single-phase 120V 60 HZ socket (within 2 m),

nominal current 10A. Switch off the machine

and proceed as follows.

1. Insert the plug into the mains socket.

2. Proceed with the recharging keeping the

recovery tank lifted (see under paragraph

“ACCESS TO THE BATTERY COMPARTMENT”

in “BEFORE USE”).

Never charge a GEL battery with a non suitable

recharger. Strictly follow the instructions

supplied by the batteries and recharger

manufacturer. In order not to cause permanent

damages to the batteries, it is necessary to

avoid their complete discharge, providing

for the recharging within a few minutes after

batteries discharge signal starts blinking.

Never leave batteries completely discharged

even if the machine is not used. In case of

traditional batteries, please check the

electrolyte level every 20 recharging cycles and

eventually fill them up with distilled water after

having carried out a complete recharge.

Danger of gas exhalations and emission of

corrosive liquids. Fire danger: do not approach

with free flames.

BATTERIES DISPOSAL

It is compulsory to hand over exhaust batteries,

classified as dangerous waste, to an authorized

institution according to the current laws.

3. Do not take off the plug from the mains

socket until the end of charge. At the end of

the recharging, remove the plug from the mains

socket.

Summary of Contents for TS120-S53-U

Page 20: ...20...