Reelmaster 5500-D

Page 1 - 4

Safety

Jacking Instructions

CAUTION

When changing attachments, tires, or performing

other service, use correct blocks, hoists, and

jacks. Make sure machine is parked on a solid lev-

el surface such as a concrete floor. Prior to rais-

ing machine, remove any attachments that may

interfere with the safe and proper raising of the

machine. Always chock or block wheels. Use jack

stands or solid wood blocks to support the raised

machine. If the machine is not properly sup-

ported by blocks or jack stands, the machine may

move or fall, which may result in personal injury.

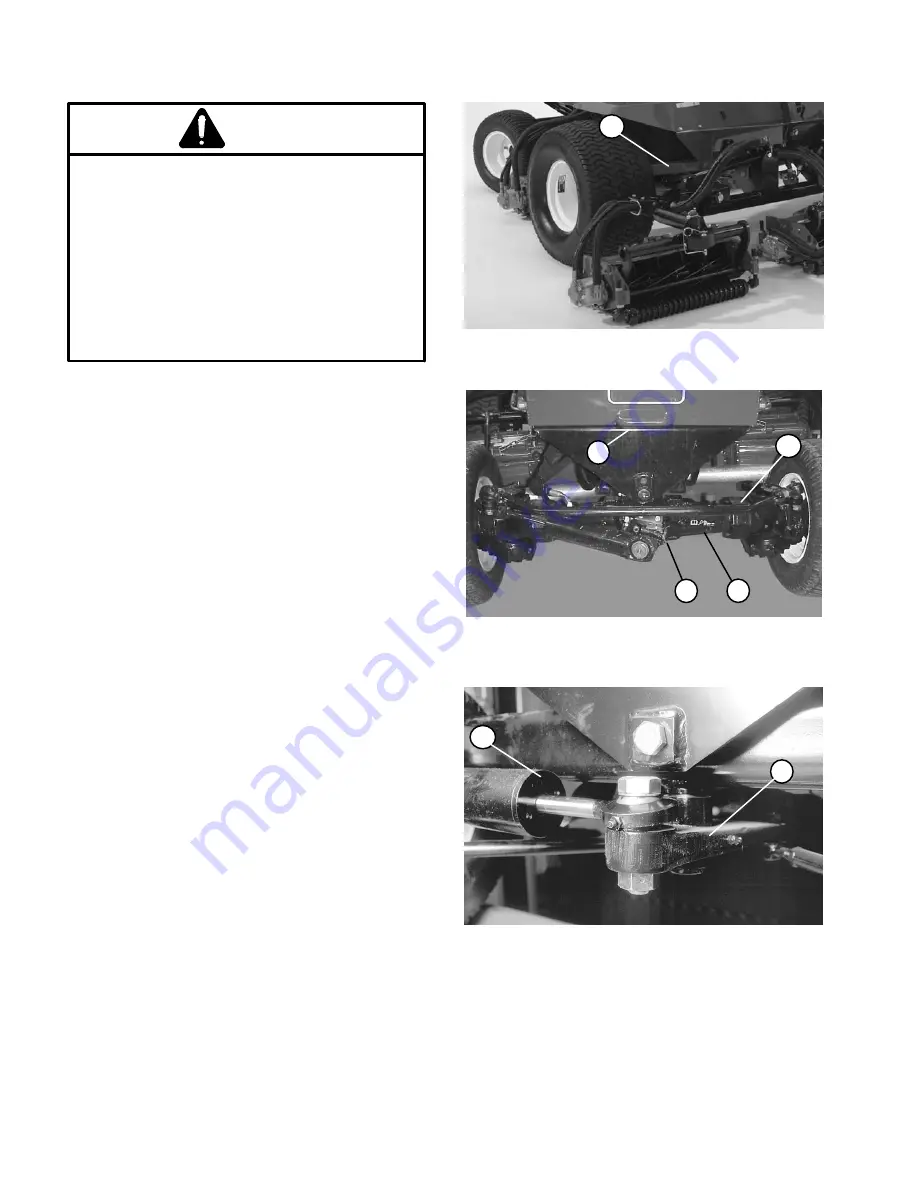

Jacking the Front End (Fig. 1)

1. Set parking brake and chock both rear tires to pre-

vent the machine from moving.

2. Position jack securely under the tie down rod that is

welded to the square tube of the front frame.

3. Position jack stands or hardwood blocks under the

square tube as close to the wheels as possible to sup-

port the machine.

Jacking the Rear End

1. The preferred method of lifting the rear end of the

machine is (Fig. 2):

A. Secure a chain fall or hoist to the tie down rod on

the rear of the frame.

B. Chock both front tires. Lift rear of the machine off

the ground.

C. On 2WD models, use jack stands or blocks under

the axle as close to the wheels as possible to secure

the machine.

D. On 4WD models, use jack stands or blocks under

the axle tube as close to the gear box housings as

possible to secure the machine.

2. If the rear of the machine can not be lifted as above:

A. On 2WD models, place jack securely under the

pivot bracket for the steering cylinder (Fig. 3).

B. On 4WD models, place jack securely under the

differential case (Fig. 2).

C. Chock both front tires. Jack rear of machine off

the ground.

Figure 1

1. Square tube (front frame)

1

1. Differential

case

2. Axle

tube

3. Gearbox

housing

4. Tie down rod

Figure 2

3

1

2

4

1. Pivot

bracket

2. Steering

Cylinder

Figure 3

2

1

D. On 2WD models, use jack stands or blocks under

the axle as close to the wheels as possible to secure

the machine.

E. On 4WD models, use jack stands or blocks under

the axle tube as close to the gear box housings as

possible to secure the machine.

Summary of Contents for 00075SL

Page 2: ...Reelmaster 5500 D ...

Page 4: ...Reelmaster 5500 D ...

Page 6: ...Reelmaster 5500 D ...

Page 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Page 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Page 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Page 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Page 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Page 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Page 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Page 290: ...Reelmaster 5500 D ...