Differential

Axle

Rev. C

Reelmaster 5500-D

Differential Axle

Page 6 - 3

Service and Repairs

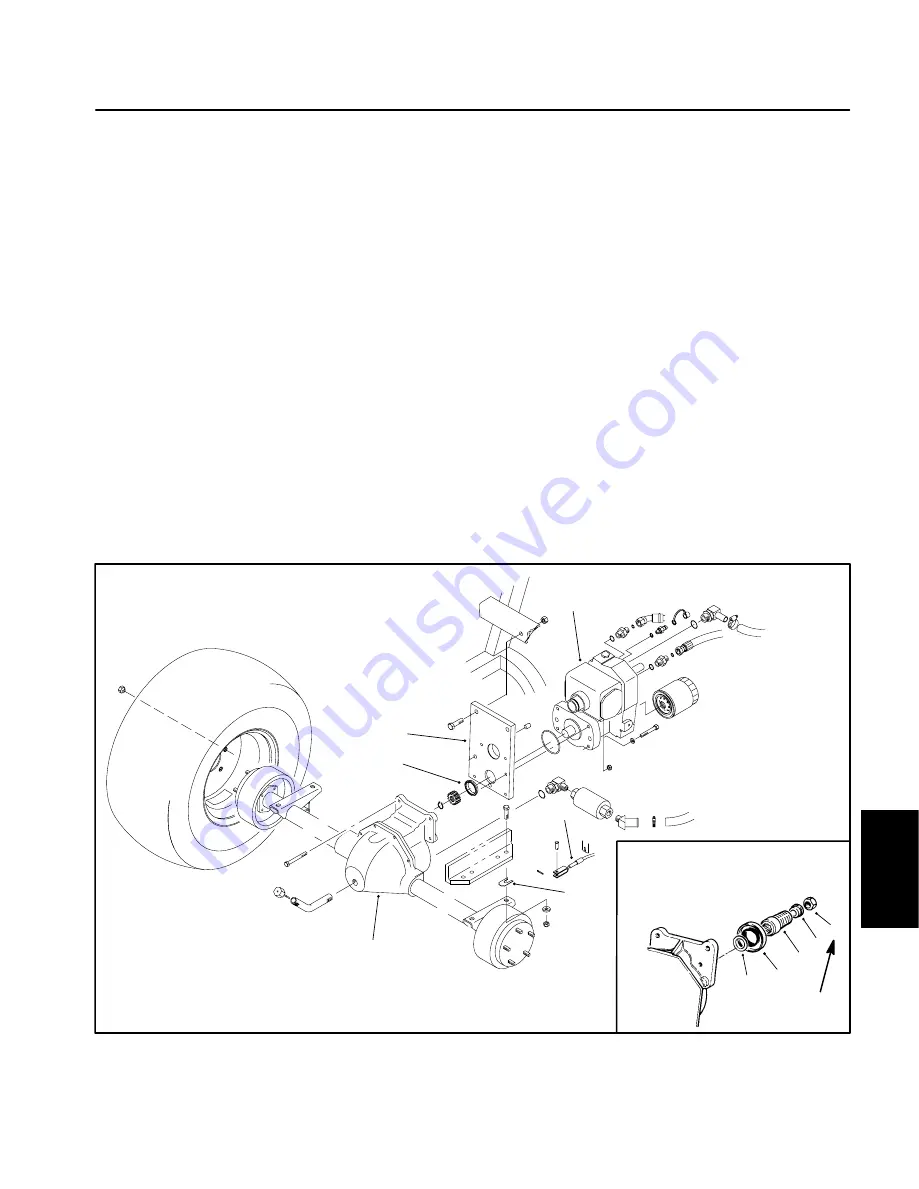

Axle Assembly Removal and Installation

1. Put machine on a level surface, lower cutting units,

stop the engine and remove key from ignition switch.

Block rear wheels to prevent machine from moving.

2. Remove the cutting units (See the Repairs section of

Chapter 8 - Cutting Units).

3. If unit is equipped with 4WD, remove rear axle drive

shaft (see Chapter 9 - 4WD Rear Axle). Remove nut,

pinion spacer and pinion coupler.

4. Remove hydrostatic transmission (See Repairs sec-

tion of Chapter 4 - Hydraulic System). Keep transmis-

sion support attached to frame and gear pump attached

to transmission support.

5. Slightly loosen all front wheel lug nuts. Jack both

front wheels off the ground and install jackstands or

blocks under traction unit frame (not axle tubes) to pre-

vent machine from falling. Remove both front wheels.

6. Remove the cotter pin and clevis pin to disconnect

the brake cable from brake actuating lever on each

brake. Loosen jam nut to remove brake cable from each

end of axle bracket. Disconnect speedometer sensor

wire connector.

7. Put a jack or blocking under differential to hold it in

place. Remove cap screws and lock nuts securing axle

mounting pads to frame. Carefully lower differential axle

and pull it out from under traction unit.

8. To install axle, reverse steps 1 - 7. Apply silicone

sealant between axle housing and transmission sup-

port. Leave axle mounting pad nuts loose. Install shims

(P/N 42-6080) between axle mounting pads and frame

to align differential with transmission support, then tight-

en axle mounting nuts.

9. Before installing pinion coupler, apply Permatex

No. 2 to external splines of pinion and internal splines of

pinion coupler. Torque nut securing pinion coupler from

75 to 90 ft-lbs. (102 to 122 Nm).

1. Hydrostatic

transmission

2. Transmission

support

3. Transmission

collar

4. Axle

shim

5. Differential

axle

6. Brake

cable

7. Nut

8. Spacer

9. Pinion

coupler

10. Seal

11. Shim

Figure 4

4

5

6

1

2

3

11

10

9

8

7

Coupler for 4WD

rear axle drive shaft

Apply Permatex No. 2 to outer

diameter of seal and internal

splines of pinion coupler

Apply silicone sealant

between axle housing and

transmission support

75 to 90 ft−lb

(102 to 122 Nm)

Summary of Contents for 00075SL

Page 2: ...Reelmaster 5500 D ...

Page 4: ...Reelmaster 5500 D ...

Page 6: ...Reelmaster 5500 D ...

Page 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Page 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Page 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Page 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Page 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Page 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Page 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Page 290: ...Reelmaster 5500 D ...