Cutting Units

Reelmaster 5500-D

Page 8 - 5

Cutting Units

Troubleshooting

There are a number of factors that can contribute to un-

satisfactory quality of cut, some of which may be turf

conditions. Turf conditions such as excessive thatch,

“sponginess” or attempting to cut off too much grass

height may not always be overcome by adjusting the

machine. It is important to remember that the lower the

height of cut, the more critical these factors are.

Remember that the “effective” or actual height of cut de-

pends on cutting unit weight and turf conditions. Effec-

tive height of cut will be different than the bench set

height of cut.

Factors That Can Affect Quality of Cut

Note:

For additional information see Toro Commercial

Products Aftercut Appearance Troubleshooting Aid

(Part No. 00076SL).

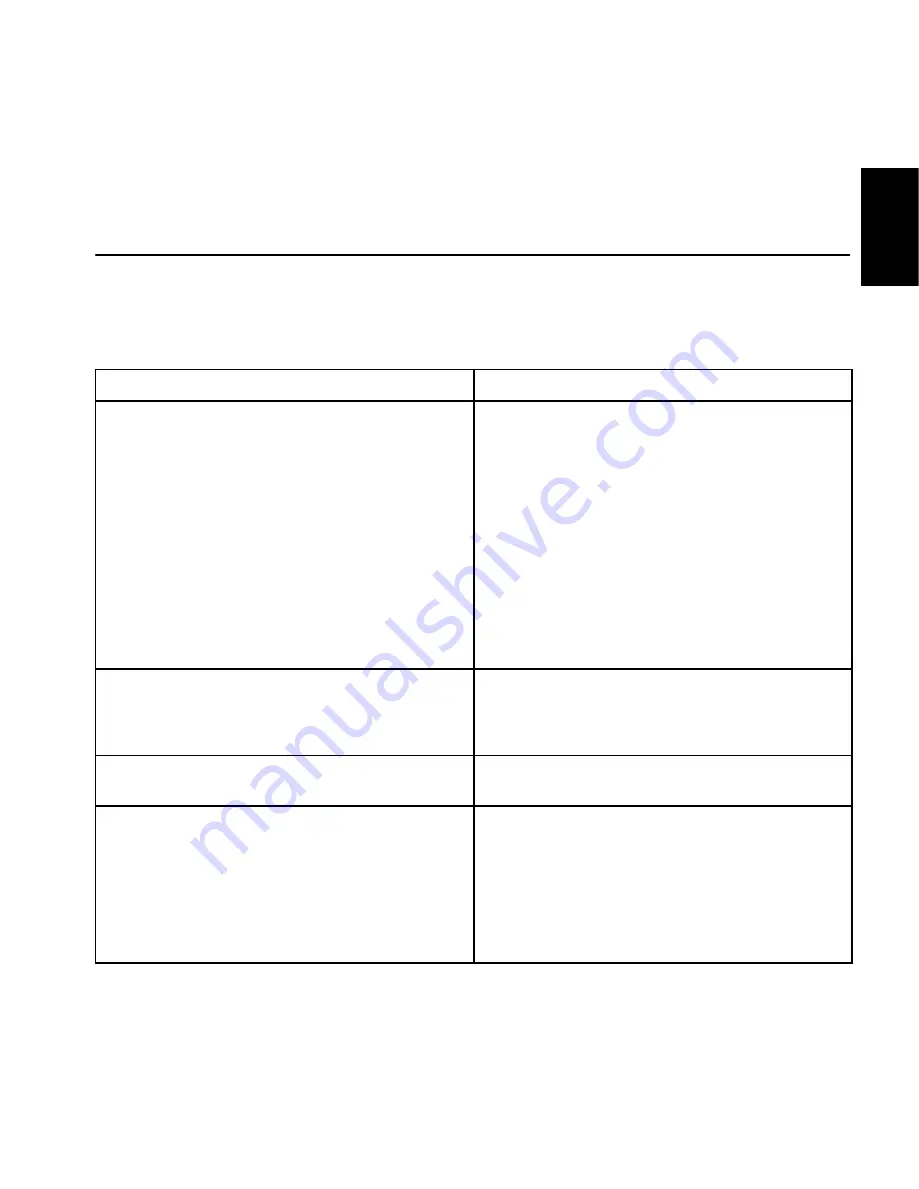

Factor

Possible Problem/Correction

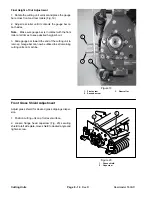

1. Reel speed and ground speed.

Adjust reel speed to settings shown on Reel Speed

Settings Graph for correct number of reel blades (5, 7,

or 11) and desired groundspeed (see Operator’s

Manual for more information).

Slow down or speed up if reel control lamp comes on.

All reels should rotate at same speed (within 150

RPM). All cutting units should have equal bedknife to

reel contact. If checking RPM, do not run reel too long

without cutting grass, or bedknife and/or reel may

overheat and “rifle”.

See other items under Troubleshooting in Chapter 4 -

Hydraulic System and Chapter 5 - Electrical System.

3. Tire pressure.

Check and inflate to specification if necessary. Must be

equal in two front tires and two rear tires.

Note: Correct tire size and inflation pressure is

important on 4WD model to prevent scuffing of turf.

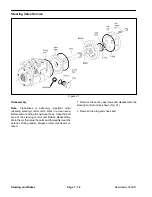

3. Reel bearing condition.

Replace bearings if worn or damaged. Do not

over-tighten bearing retainer nut.

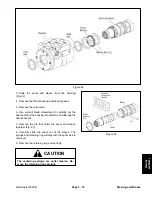

4. Reel and bedknife sharpness.

Reel and/or bedknife that has rounded cutting edges or

“rifling” cannot be corrected by tightening bedknife to

reel contact. Grind reel to remove taper and/or rifling

(grooved or wavy appearance). Grind bedknife to

sharpen and/or remove rifling (Most common cause of

rifling is bedknife to reel contact that is too tight).

Note: New bedknife must be ground or backlapped

after installing on bedbar.

Summary of Contents for 00075SL

Page 2: ...Reelmaster 5500 D ...

Page 4: ...Reelmaster 5500 D ...

Page 6: ...Reelmaster 5500 D ...

Page 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Page 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Page 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Page 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Page 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Page 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Page 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Page 290: ...Reelmaster 5500 D ...