Reelmaster 5500-D

Page 8 - 28

Cutting Units

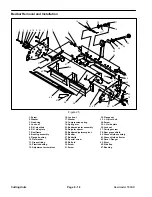

12. Insert steering pin into the pivot knuckle if you wish

to keep cutting units locked in a straight line during op-

eration. If no steering pin is used, the cutting units will

steer themselves as the traction unit turns (Fig. 39).

13. Hook spring wire around bottom of steering pin

(Fig. 39).

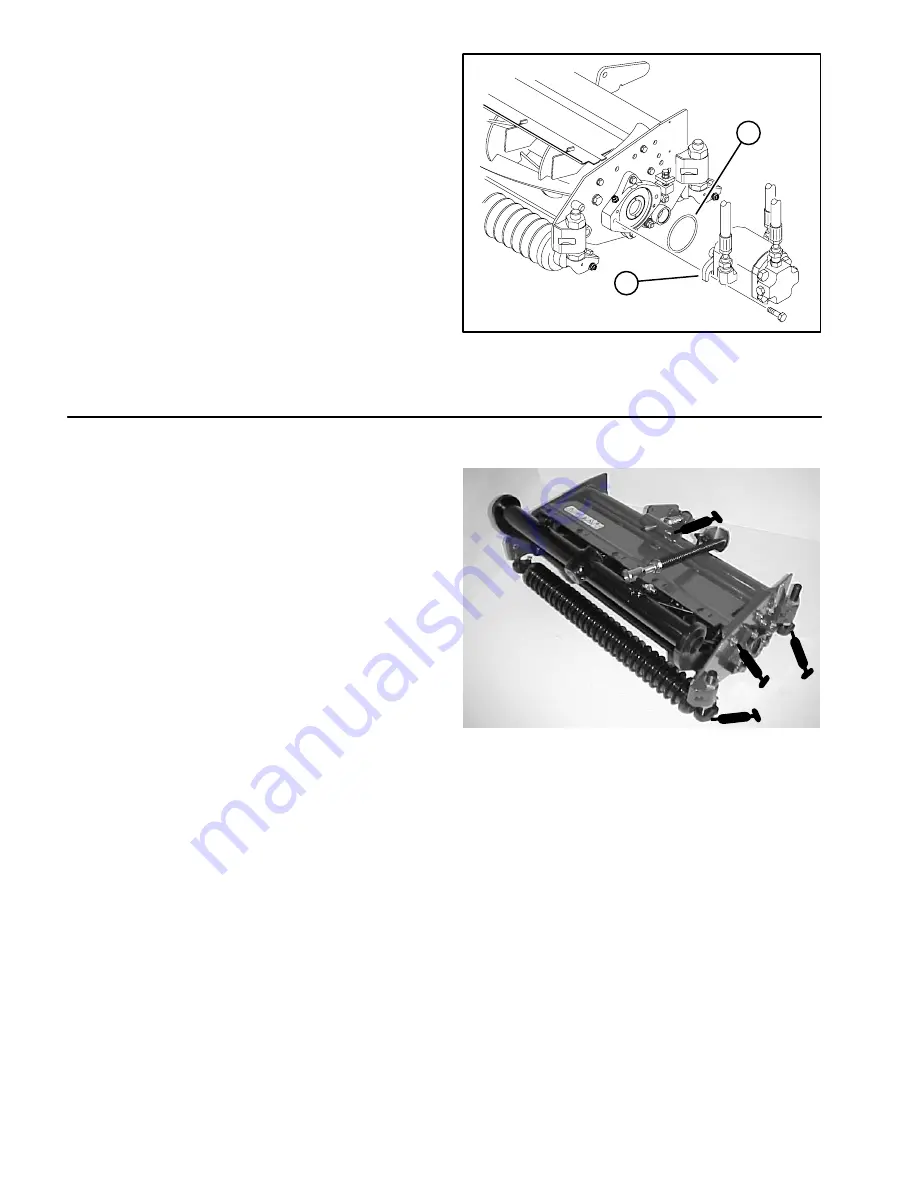

14. Mount the motor to the drive end of the cutting unit

and secure with two capscrews provided (Fig. 40).

Figure 40

1. Motor

2. O-ring

1

2

Lubrication

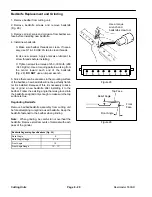

Each cutting unit has seven grease fittings that must be

lubricated regularly with No. 2 General Purpose Lithium

Base Grease (Fig. 41).

IMPORTANT: Lubricating cutting units immediately af-

ter washing helps purge water out of bearings and in-

creases bearing life.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. The grease fitting locations and quantities are as fol-

lows:

A. Two at front roller ends

B. Two at rear roller ends

C. Two at reel bearings

D. Bedknife adjuster

3. Wipe each grease fitting with a clean rag.

4. Apply grease until pressure is felt against handle.

5. Wipe excess grease away.

Note:

Apply grease to reel bearing cavities until a

small amount is evident at the inboard reel seal.

(2)

(2)

(2)

Figure 41

Summary of Contents for 00075SL

Page 2: ...Reelmaster 5500 D ...

Page 4: ...Reelmaster 5500 D ...

Page 6: ...Reelmaster 5500 D ...

Page 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Page 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Page 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Page 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Page 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Page 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Page 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Page 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Page 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Page 290: ...Reelmaster 5500 D ...