Maintenance

Lubrication

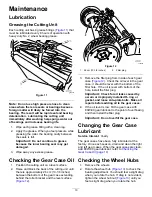

Greasing the Cutting Unit

Each cutting unit has 4 grease fittings (

) that

must be lubricated every 8 hours of operation with

heavy duty No. 2 wheel bearing grease.

g026934

Figure 11

Note:

Do not use high pressure hose to clean

areas where there are seals or bearings because

foreign matter will likely be forced into the

bearing. The result will be rapid seal and bearing

deterioration. Lubricating the cutting unit

immediately after washing helps purge water out

of bearings and increases bearing life.

1.

Wipe each grease fitting with a clean rag.

2.

Apply the grease. When you feel pressure while

greasing the roller, the bearing cavity between

the seals is full.

Important:

Do not continue to grease

because the inner bearing seal may get

damaged.

3.

Wipe away any excess grease.

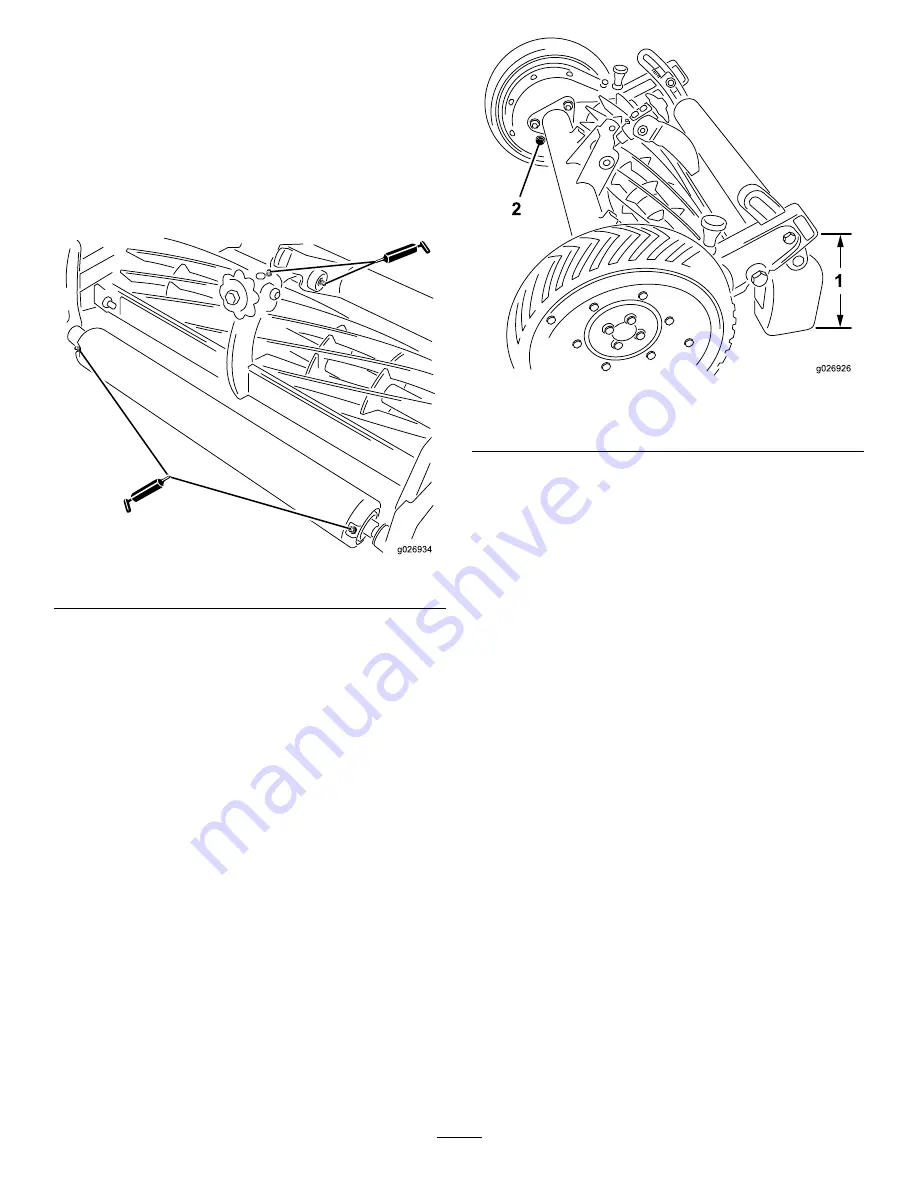

Checking the Gear Case Oil

1.

Position the cutting unit on a level surface.

2.

Raise and block the back of the cutting unit until

there is approximately 26 cm (10-1/4 inches)

between the bottom of the gear case extending

behind the roller bracket and the level surface

(

).

g026926

Figure 12

1.

26 cm (10-1/4 inches)

2.

Filler plug

3.

Remove the filler plug from inside of each gear

case (

). Check the oil level in the gear

case; it should be level with the bottom of the

filler hole. If the oil is level with bottom of the

hole, install the filler plug.

Important:

Check for oil leaks caused by

a worn or improperly installed O–ring or

gasket, and loose side-plate bolts. Make all

repairs before adding oil to the gear cases.

4.

If the oil level is low, fill the gear case with

80W-90 gear lubricant to the point of overflowing

and then install the filler plug.

Important:

Do not overfill the gear case.

Changing the Gear Case

Lubricant

Service Interval:

Yearly

The gear cases have been fully lubricated at the

factory. Once each season, drain and clean the right

and left gear cases. When the gear cases are clean,

add 80W-90 gear lubricant; refer to

Gear Case Oil (page 10)

.

Checking the Wheel Hubs

1.

Remove the wheels.

2.

Rotate the wheel hub (

) to check the

bearing adjustment. You should feel a slight drag

when you rotate the hub. If drag is not evident,

tighten the wheel hub nut (

) until you

feel a slight drag when you rotate the hub.

10