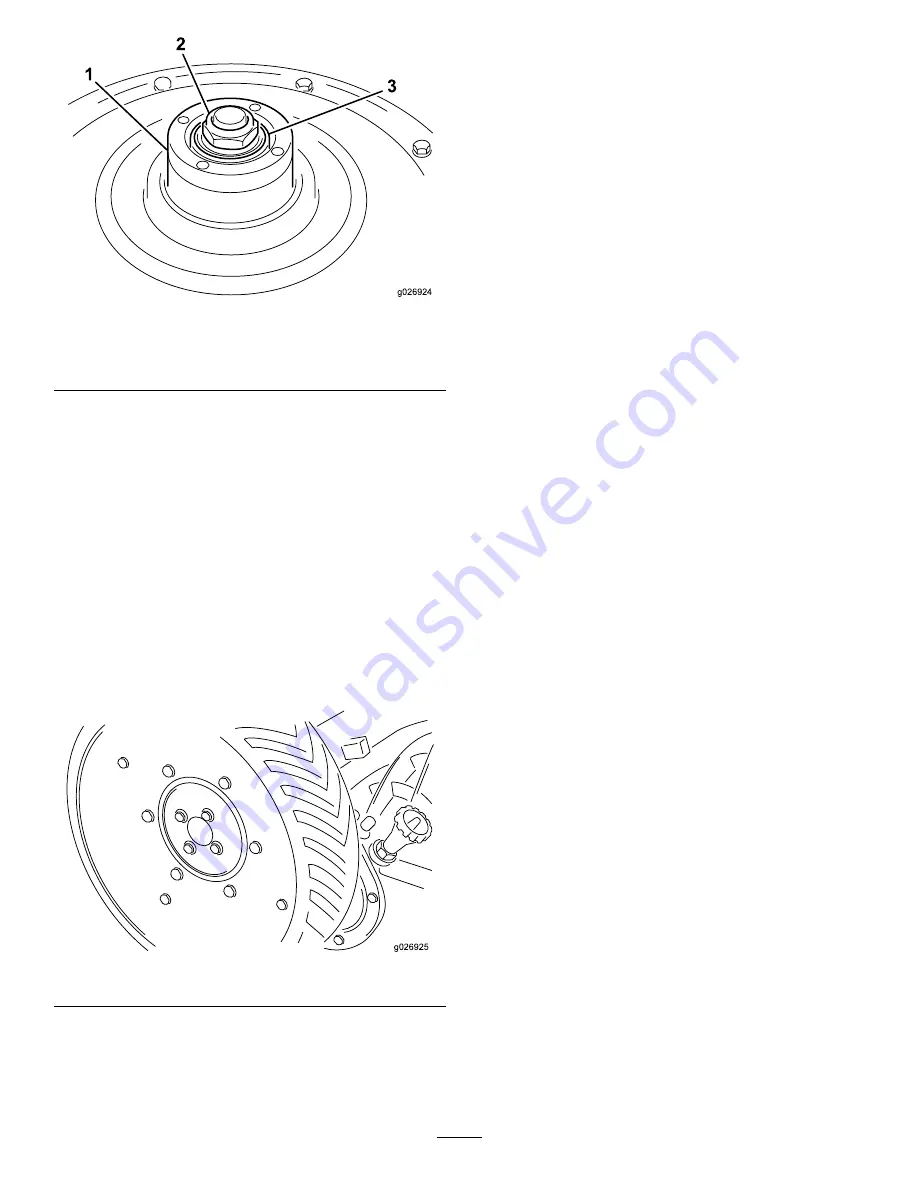

g026924

Figure 13

1.

Wheel hub

3.

O–ring

2.

Wheel hub nut

Important:

Do not over–tighten the wheel

hub nut because the bearing will wear

rapidly.

3.

Check the O–ring to assure it is not damaged,

and make sure that it is seated in the inside

diameter of the wheel hub (

).

Important:

An O–ring that is damaged or

installed incorrectly will allow oil to leak out

of the gear case. If enough oil leaks out,

mechanical damage will likely result.

4.

If pneumatic wheels are installed, set the tire

pressure at 241.3 Kpa (35 psi).

5.

Install the drive wheels with cap screws and lock

washers (

).

g026925

Figure 14

Checking the Fasteners

and Reel Bearings

1.

Rotate the center adjusting knob until the

bedknife does not contact the reel. Try to spin

the reel. If the reel does not spin, adjust the reel

bearings; refer to Adjusting the Reel Bearing in

the Maintenance Section. If the reel spins freely,

proceed to the next step.

2.

Try to move the reel back and forth. If the reel

can be moved, adjust the reel bearings; refer to

Adjusting the Reel Bearings (page 11)

.

3.

Check and tighten all nuts, bolts, and screws to

ensure that all parts are secure.

Adjusting the Reel Bearings

If end play is evident in the reel or if the cutting unit

has been disassembled, an adjustment to the reel

bearing may be necessary.

1.

Remove the 4 screws securing the left wheel to

the wheel hub and remove the wheel. Place the

wheel under the gear case for support.

2.

Raise and block the back of the cutting unit

until there is 0.178 to 0.203 m (7 to 8 inches)

between the bottom of the gear case extending

behind the roller bracket and the level surface.

3.

Remove the 3 cap screws securing the

inspection cover to the gear case cover.

4.

In small increments, rotate the adjusting nut

on the reel shaft, in the clockwise direction to

remove all end play from the reel.

Note:

Stop the reel from rotating.

5.

When the end play is removed, rotate the nut an

additional 1/4 turn to preload the bearing.

6.

Install the inspection cover and the wheel.

Grinding the Cutting Unit

Note:

For detailed sharpening information, refer

to the

Toro Manual for Sharpening Reel and Rotary

Mowers

, Form No. 09168SL.

New and old bedknives should be ground attached

to the bedbar; this ensures rigidity during grinding

and ensures a true knife. Refer to

when

grinding the knives and obtain as near as possible the

relief angles indicated. In grinding, avoid hard contact

between the knife and the grinding wheel. Hard

contact causes excessive heat buildup, resulting in

premature wearing of the grinding wheel and reduced

life of the knife.

11