Note:

The lapping solution must be kept in free

flowing condition to get even distribution on the

bedknife and reel.

The lapping procedure is as follows:

1.

Adjust the bedknife to the reel so that light

contact is evident.

2.

Operate the lapping machine so that the reel

turns in a reverse direction. Apply lapping

solution continuously and maintain light

bedknife-to-reel contact.

3.

Stop the lapping machine periodically to check

the cutting surfaces for sharpness. Continue

lapping until the sharp cutting edges have been

restored.

Note:

If the cutting edges are severely rounded,

both sharpening and lapping may be required.

4.

Wash off all the lapping solution. Using paper,

check for sharpness along the entire length of

each reel blade. If the paper cannot be cut

cleanly along the entire length of each reel

blade, continued lapping is necessary.

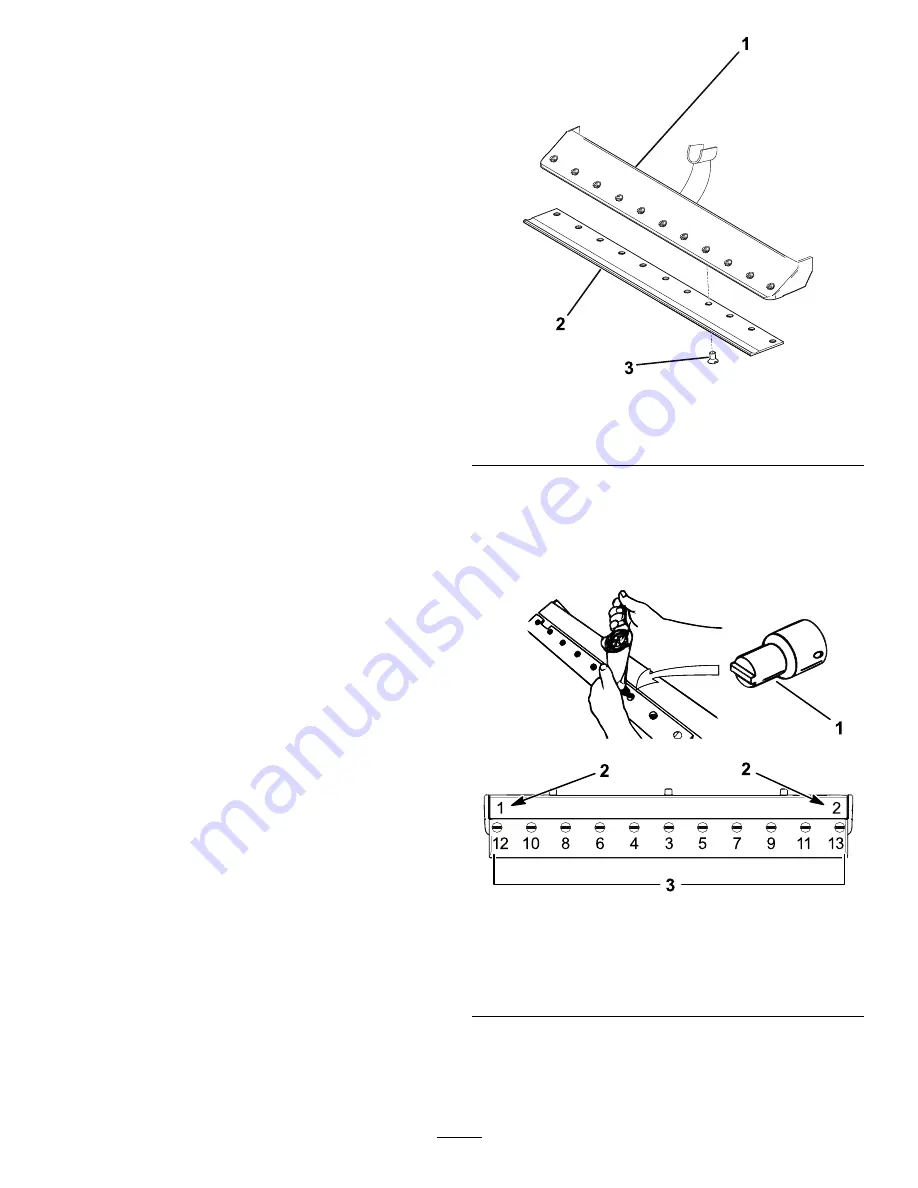

Replacing the Bedknife

1.

To replace the bedknife, remove the 11 screws

holding the knife to the bed bar.

2.

Remove the rust, scale, and corrosion from the

bedbar surface and apply a thin layer of oil to

the bedbar surface.

3.

Clean the screw threads.

4.

Apply anti-seize compound to the screws and

install the bedknife to the bedbar as follows

(

):

g282051

Figure 18

1.

Bedbar

3.

Screw

2.

Bedknife

A.

Torque the 2 outer screws to 1 N∙m (10

in-lb); refer to

.

B.

Working form the center of the bedknife,

torque the screws to 23 to 28 N∙m (200 to

250 in-lb); refer to

g282050

Figure 19

1.

Bedknife screw tool

3.

Torque to 23 to 28 N∙m

(200 to 250 in-lb).

2.

Install and torque these

first to 1 N∙m (10 in-lb).

5.

True the bedknife attached to the bedbar

by grinding. Refer to the Toro Manual for

Sharpening Reel and Rotary Mowers, Form No.

09168SL

13