6.

After the bedknife has been ground and is true,

adjust the reel, roller, and wheel bearing; refer to

Adjusting the Reel, Roller, and Wheel Bearing

(page 14)

.

Adjusting the Reel, Roller,

and Wheel Bearing

After the initial 30 operating hours, check the reel

bearing, roller bearing, and wheel bearing. Thereafter,

check these parts every 200 to 250 operating hours.

If necessary, adjust the reel bearing. If necessary,

adjust the roller bearing. If necessary, adjust the

wheel bearing.

Servicing the Roller

Disassembling the Roller

1.

Remove the brackets and washers from each

end of the roller and inspect the bushings.

2.

Remove elastic stop nut.

Note:

After the elastic stop nut has been

removed, slide the sleeve off the roller shaft.

Point the end of roller downward into a container,

at the same time pulling the roller shaft out,

allowing lubricant to drain from the roller.

3.

If the roller shaft is to be replaced, remove the

double jam nuts.

4.

Remove the remaining sleeve and seals from

both ends of the roller.

5.

Remove the bearing cones from each end of the

roller.

6.

Remove the bearing cups with caution.

7.

Remove the inner seals by using a seal remover.

Assembling the Roller

1.

Lightly oil the lips of the inner seals. Install the

inner seals on each end of the roller, making

sure that the garter springs face inboard.

2.

Replace the bearing cups and insert the bearing

cones into the roller.

3.

Lightly oil the lips of the outer seals. Install the

outer seals on each end of the roller, making

sure that the garter springs face inboard.

4.

Slide 1 sleeve onto the roller shaft against the

double jam nuts.

5.

Wrap the threaded area of the roller shaft

with cellophane tape to protect the seals, and

carefully slide the shaft through the right side

of the roller. Slide the roller shaft into the roller

until it penetrates the inner most oil seal on the

right side.

6.

Pour approximately 0.5 L (16 fl oz) of SAE 90 or

140 gear oil into the roller housing.

7.

After the oil has been added, carefully push the

roller shaft through the entire roller assembly.

Remove the cellophane tape.

8.

Install the sleeve onto the roller shaft and slide

up against the bearing cone.

9.

Install the elastic stop nut and secure it by

holding the double jam nuts. Tighten the elastic

stop nut.

Note:

Tighten the elastic stop nut until all axial

and radial motion has been removed from the

roller shaft and bearings. Ensure that the roller

rotates freely on the shaft.

10.

Grease the bearings with heavy duty No. 2

wheel bearing grease.

11.

Install the washers and install the left and right

bracket and the bushing assemblies.

Important:

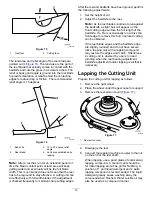

After the cutting unit has been

completely assembled, perform the following

critical adjustments:

A.

Check the reel bearings and the fasteners.

B.

Set the height of cut.

C.

Adjust the bedknife to the reel.

14