Note:

These are bench settings. The cutting

unit will cut at a different height in turf because

of grass conditions and the weight of the cutting

unit.

4.

To make a finer adjustment to the cutting height

or to adjust the roller, the adjusting nut may be

moved 1/2 notch or 1.19 mm (3/64 inch) by

using the following procedure:

A.

Remove the capscrew and the adjusting nut

securing the roller bracket to the gear case.

Do not move the roller bracket.

B.

Reposition the capscrew and the adjusting

nut to the upper hole in the gear case.

C.

Slide the roller bracket up or down 1/2 notch

to position the adjusting nut into the correct

notch and tighten the capscrew.

Operating Tips

•

Mowing Speed

—The cutting unit is designed to

cut grass well at any ground speed between 1.6

and 9.66 km/h (1 and 6 mph) but for most turf

conditions, ground speeds of 6.4 to 9.66 km/h (4

to 6 mph) produce the best quality of cut. Ground

speed, however, must be reduced when turning

because excessive speed will cause the outside

cutting units to bounce and skip on the turf.

Excessive heat, caused by the reel spinning too

fast, can also damage the bedknife and the reel.

Since the grass lubricates the bedknife and reel

during operation, slow down when cutting sparse

grass, extremely dry grass, or when trimming. Any

lack or significant reduction of lubrication produces

excessive heat buildup and, subsequently, heavy

contact between the bedknife and the reel, which

results in uneven bedknife wear and poor quality

of cut. Therefore, reels must be disengaged and

stopped before mowers are transported across

parking lots, roads, or whenever the lubrication

is minimal.

•

Height of Cut

—To determine the effective height

of cut, the length of the grass to be cut must be

checked. The height of cut should be set and the

turf mowed frequently so that no more than 1/3 of

the leaf is cut off. If the cutting unit is equipped

with pneumatic tires, pressure must be maintained

at 241.3 kpa (35 psi). Low tire pressure can cause

bedknife to dip into the grass and scalp the turf.

An uneven cut will likely result.

•

Operating Sound

—A cutting unit that is adjusted

correctly gives off a whispering sound when

operated. If there are buzzing, clicking, or metallic

sounds, the cutting unit has probably been

operated with heavy contact between the bedknife

and the reel. The reel or bedknife could also have

hit a foreign object. A noisy cutting unit must be

stopped, repaired, and adjusted or severe damage

will result.

•

Mowing Pattern

—To prevent grass from lying

down and improved appearance of the turf,

alternate mowing directions if possible, each time

an area is cut.

Causes of Poor Quality of

Cut

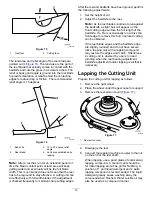

1.

Bedknife/Reel Contact

(

) – There must

be light contact between the bedknife and the

reel to keep the cutting edges sharp and to

produce an excellent quality of cut. By contrast,

cutting units operated without light contact allow

abrasive materials and grass to pass between

the bedknife and the reel. This eroding action

rounds off the bedknife and the reel cutting

edges, which results in a poor quality of cut. If

the cutting edges become round, the bedknife

and the reel must be lapped. Excessive rounding

off of the cutting edges may require that the

bedknife and the reel be ground and lapped.

Never compensate for round cutting edges by

tightening the bedknife adjusting knob until there

is heavy contact because the bedknife and the

reel will wear unevenly and cause a rifling effect.

g026931

Figure 8

1.

Sharp edges, light contact

3.

Contact adjustment, dull

edges

2.

No contact, edges get

dulled

Note:

Rifling is the uneven or wavy condition

that develops on the bedknife and the reel when

there is heavy contact between these two parts

(

). Streaks of uncut grass and an overall

poor quality of cut are signs of rifling. Grinding

the bedknife and reel is the only way to repair a

rifled cutting unit.

8