18

SET-UP INSTRUCTIONS

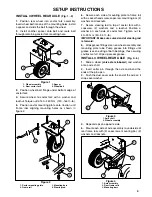

4.

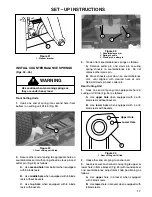

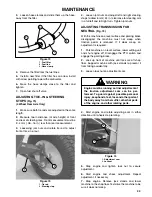

To tension rear counterbalance spring, rotate

counterbalance knob (Fig. 35) until distance between

center of anchor bolt opening and inside of frame

X"

is

as follows:

A.

Distance X" is

50mm

when equipped with 5 or

8 blade reels without baskets.

B.

Distance X" is

15mm

when equipped with 5 or

8 blade reels with baskets.

Figure 35

X"

5

4

3

1

2

1. Rear counterbalance knob

2. Anchor bolt

3. Spacer

4. Frame bracket

5. Counterbalance spring

IMPORTANT

:

These are recommended settings.

Readjust spring positions to attain optimum

performance and counterbalance. By raising

spring locations, cutting unit weight on ground is

reduced and traction is increased.

ADD REAR BALLAST

This unit complies with ANSl B 71.4-1984 Standard

and CE when equipped with rear ballast. Use the

following chart to determine weight or combinations of

weights needed.

Traction Unit

Weight Required

Configuration

3 Wheel Axle

and equipped

with Baskets

Calcium Chloride in rear tire

and rear weights, Part No.

24-5790 and 24-5780.

4 Wheel Axle

and equipped

with Baskets

Calcium Chloride in rear tire

and rear weights,

Part No. 24-5780.

IMPORTANT: If a puncture occurs in a tire with

calcium chloride, remove unit from turf area as

quickly as possible. To prevent possible damage to

turf, immediately soak affected area with water.

Either Type 1 (77%) or Type 2 (94%) commercial

calcium chloride flake may be used.

Plain water freezes solid at 32

_

F (0

_

C). The 3-1/2

pound (1 .6 kg) calcium chloride to one gallon (3.8 L) of

water solution is slush free to -12

_

F (-24

_

C), and will

freeze solid at -52

_

F (-46

_

C). The 5 pound (2.3 kg)

per gallon (liter) solution is slush free to -50

_

F

(-45

_

C) and will freeze solid at -62

_

F (-52

_

C).

Tires should be filled to approximately 75% capacity

(valve level with valve at the top).

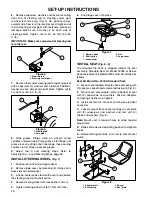

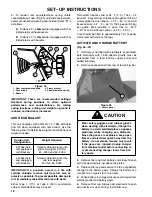

ACTIVATE AND CHARGE BATTERY

(Fig. 36-37)

1.

If Battery is not filled with electrolyte or activated,

bulk electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet and

added to battery.

2.

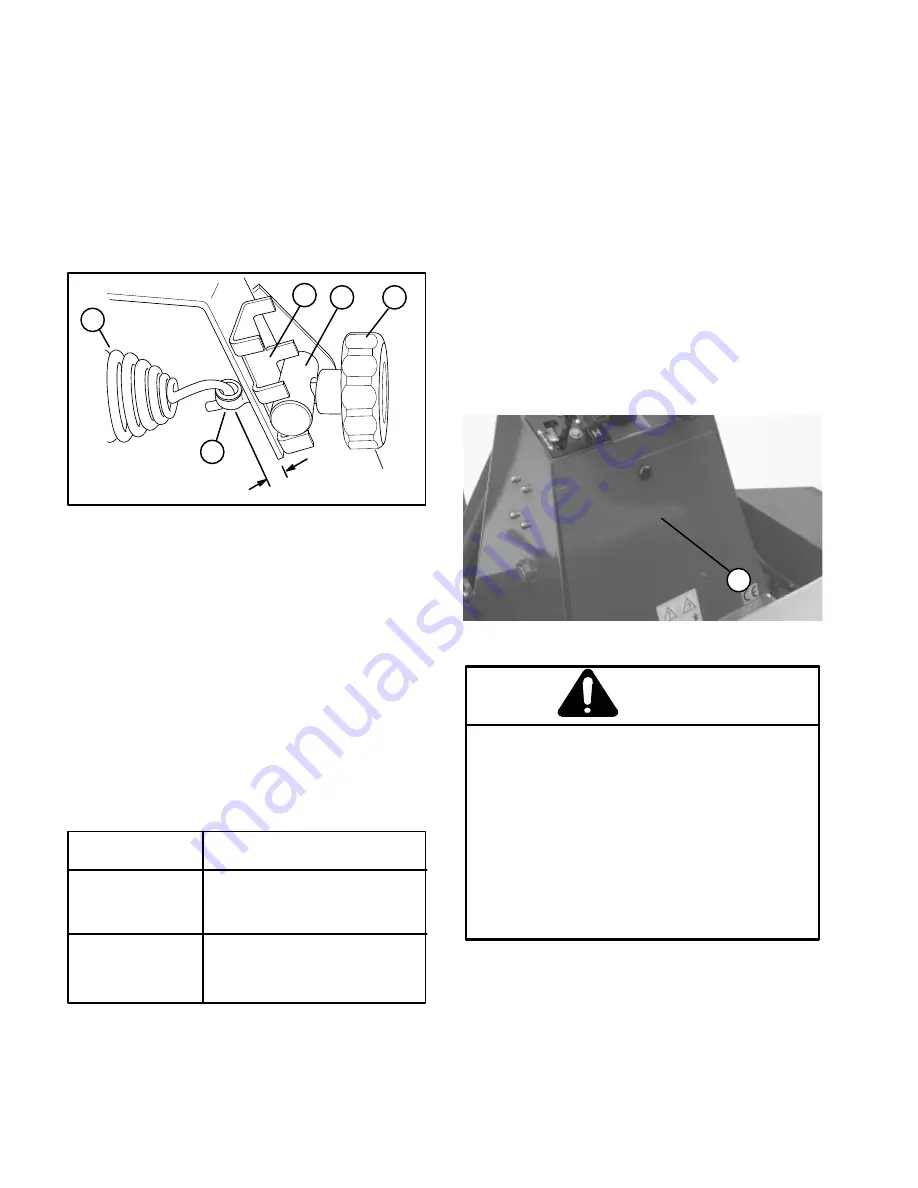

Remove access panel from rear of tower (Fig. 36).

1. Access panel

Figure 36

1

Wear safety goggles and rubber gloves

when working with electrolyte. Charge the

battery in a well ventilated place so gasses

produced while charging can dissipate.

Since the gases are explosive, keep open

flames and electrical spark away from the

battery; do not smoke. Nausea may result

if the gases are inhaled. Unplug charger

from electrical outlet before connecting to

or disconnecting charger leads from batĆ

tery posts.

CAUTION

3.

Remove filler cap from battery and slowly fill each

cell until electrolyte is just above the plates.

4.

Replace filler cap and connect a 3 to 4 amp battery

charger to the battery posts. Charge the battery at a

rate of 3 to 4 amperes for 4 to 8 hours.

5.

When battery is charged, disconnect charger from

electrical outlet and battery posts.

6.

Remove filler cap. Slowly add electrolyte to each

cell until level is up to fill ring. Install filler cap.

Summary of Contents for 02000

Page 6: ... ...

Page 12: ... ...

Page 17: ... 0 0 2 3 0 13 0 0 0 0 0 0 1 0 0 2 0 0 0 2 0 2 ...

Page 19: ... ...

Page 23: ... ...

Page 28: ... ...

Page 37: ... ...

Page 39: ... _ _ ...