Service and Repairs

Hydraulic Reel Motor

IMPORTANT

When performing the maintenance procedures on the cutting units,

carefully position the cutting unit reel motors to prevent damage to

the motors or hydraulic hoses.

Removing the Hydraulic Reel Motor

1. Park the machine on a clean and level surface, lower the cutting units

completely to the ground, shut off the engine, set the parking brake, and

remove the key from the key switch.

2. Loosen the two (2) cap screws that secure the hydraulic reel motor to the

cutting unit side plate. Rotate the motor clockwise and remove the motor

from the cutting unit.

3. Inspect the reel insert splines for wear. Replace if necessary (refer to

).

4. Place protective plastic cap (refer to

Special Tools (page 2–13)

) into the hole

in the cutting unit side plate to prevent debris entry into reel bearing area.

Installing the Hydraulic Reel Motor

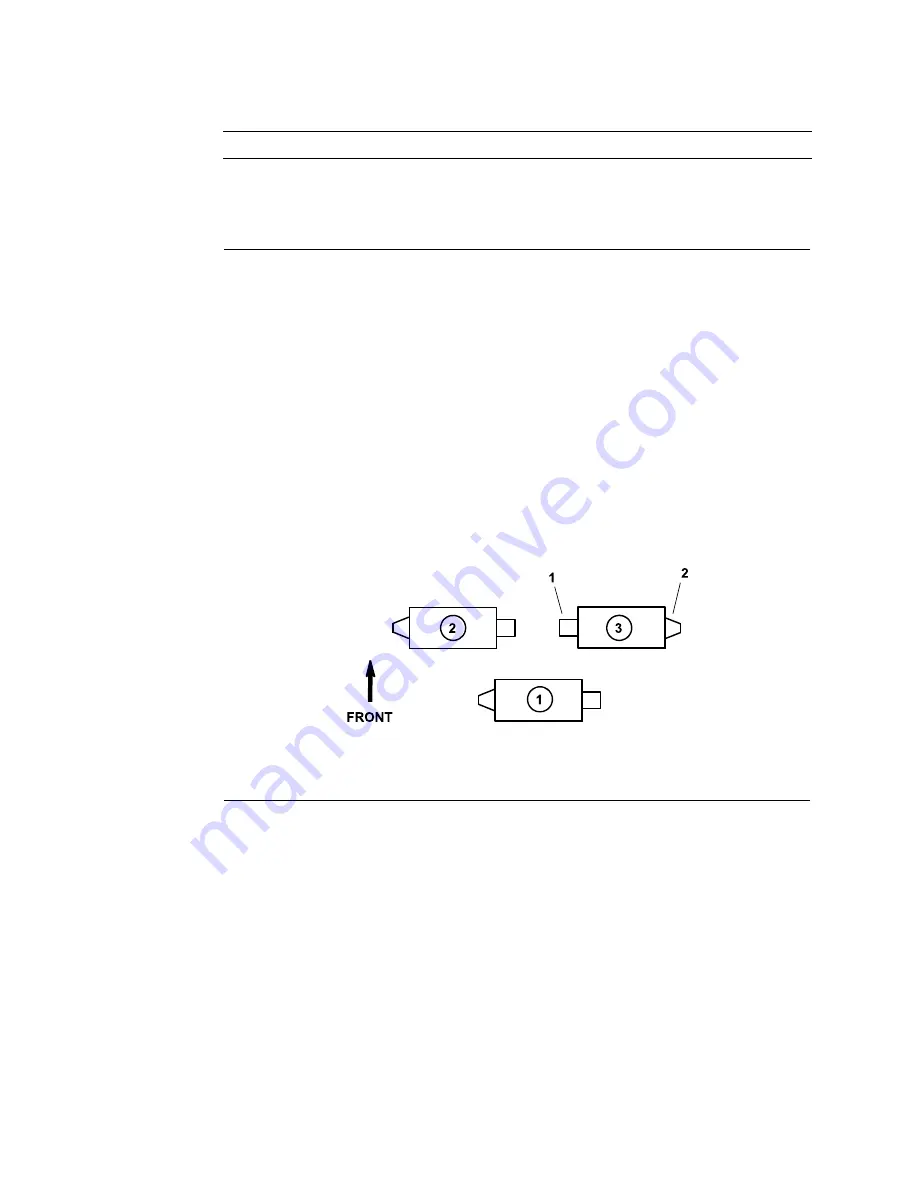

g343373

Figure 165

1.

Reel motor location

2.

Weight location

Note:

Refer to

for correct placement of the cutting unit reel motors

and weights.

1. Coat spline shaft of the reel motor with No. 2 multipurpose lithium base

grease.

2. Install the cap screws for the reel drive motor into the cutting unit side plate

and leave approximately 12.7 mm (1/2 inch) of threads exposed on each

screw.

DPA Cutting Units: Service and Repairs

Page 8–6

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......