Mow/Backlap Spool (

and

) (continued)

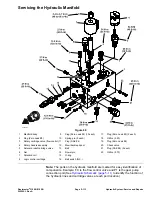

B. Carefully push spool down into mow manifold port until lower O-ring and

back-up ring groove is exposed on bottom of manifold. Install lower

O-ring and back-up ring to spool. Apply a light coating of grease to O-ring.

C. Carefully raise mow/backlap spool until upper retaining ring groove on

spool is exposed on top of manifold. Install upper retaining ring.

D. Push mow/backlap spool down and install lower retaining ring to spool.

E. If handle was removed from spool, position spool so handle location of

spool is between stop pins. Apply Loctite 603 Retaining Compound (or

equivalent) to threads on handle and install handle into spool.

F. Place ball and dowel pin in backlap switch manifold port. Install new

O-ring onto backlap switch. Thread backlap switch into port and torque

27 N·m (20 ft-lb)

.

Hydraulic System: Service and Repairs

Page 5–118

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......