Testing (continued)

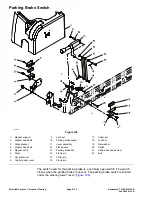

g226814

Figure 133

5. Put the end of the switch in a container of fluid with a thermometer and then

slowly heat the fluid (

).

CAUTION

The fluid is hot and could cause personal injury or fire.

Handle the hot fluid with extreme care.

6. Check the resistance of the switch with a multimeter (ohms setting) as the oil

temperature increases. The high-temperature shutdown switch is normally

open.

7. The high temperature shutdown switch should close between 107° and

113°C (225° and 235°F).

8. Allow oil to cool while observing temperature.

9. The high temperature shutdown switch should open at approximately 104°C

(219°F).

10. If the switch does not meet the specifications, replace the switch.

11. After you complete the testing, install the temperature switch to the engine

housing, do the following steps:

A. Clean the threads of the housing and switch. Apply thread sealant to

the threads of the switch.

B. Thread the switch into the housing; torque the switch to

29.4 to 39.2

N∙m (22 to 28 ft-lb)

.

C. Connect the harness wires to the temperature switch.

12. Fill the engine cooling system; refer to the

Traction Unit Operator’s Manual

.

13. Lower the hood and secure it with the latches.

Electrical System: Component Testing

Page 6–32

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......