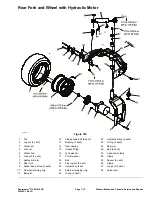

Removing the Rear Fork and Wheel

1. Park machine on a level surface, lower cutting units, stop engine, engage

parking brake, and remove key from the key switch.

2. Remove the hood from the machine.

3. Separate the hydraulic cylinder from the rear fork as follows:

A. Remove both jam nuts securing the ball joint to the rear fork.

B. Separate the ball joint from the rear fork.

C. Swing cylinder clear of the rear fork.

CAUTION

Before jacking up the machine, review and follow

Instructions (page 1–7)

.

4. Jack up rear wheel enough to allow the removal of the rear fork.

5. Remove lug nuts from drive studs. Remove tire with wheel rim from wheel

hub.

6. Remove four lock nuts and socket head screws securing the hydraulic motor

to the rear fork. Remove the motor from the fork and position it away from

the fork.

CAUTION

Support the front fork to prevent its falling during removal and

installation. Personal injury or damage to the fork may result from

improper handling.

7. Remove the bolt, thrust washer, and lock washer from the rear fork shaft.

8. Lower the rear fork from machine.

9. Check the bushings for wear and damage. Replace if necessary.

Installing the Rear Fork and Wheel

1. If removed, install the bushings into the rear fork.

2. Position the rear fork through the frame.

3. Install the lock washer, thrust washer, and bolt to the rear fork shaft. Torque

the bolt from

81 to 108 N·m (60 to 80 ft−lb)

. Make sure that the fork turns

freely.

4. Install the hydraulic motor to the rear fork. Secure the motor to the fork with

four hex socket head screws and lock nuts.

5. Secure wheel rim to the wheel hub with four lug nuts. Torque the nuts from

61 to 88 N·m (45 to 65 ft-lb)

.

6. Lower the rear wheel to the ground.

7. Secure the hydraulic cylinder to the rear fork as follows:

A. Swing cylinder to the rear fork.

B. Install the ball joints to the rear fork.

C. Secure ball joint to the rear fork with both jam nuts. Torque the nuts from

115 to 156 N·m (85 to 115 ft-lb)

.

Wheels, Brakes and Chassis: Service and Repairs

Page 7–14

Reelmaster

®

3100-D/3105-D

20252SL Rev A

Summary of Contents for 03200 Reelmaster 3100-D

Page 4: ...NOTES NOTES Page 4 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 6: ...g341979 Figure 1 Preface Page 6 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 10: ...Preface Page 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 20: ...Safety Safety and Instructional Decals Page 1 10 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 44: ...Specifications and Maintenance Special Tools Page 2 24 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 224: ...Hydraulic System Service and Repairs Page 5 148 Reelmaster 3100 D 3105 D 20252SL Rev A ...

Page 385: ......