8

Maintenance

Note:

Determine the left and right sides of the machine

from the normal operating position.

Lubrication

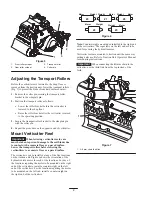

Each cutting unit has (7) grease fittings (Fig. 8) that must

be lubricated regularly with No. 2 General Purpose Lithium

Base Grease.

The lubrication points are front roller (2), rear roller (2),

reel bearing (2) and bedknife adjuster.

Important

Lubricating cutting units immediately after

washing helps purge water out of bearings and increases

bearing life.

1.

Wipe each grease fitting with a clean rag.

2.

Apply grease until clean grease is seen coming out of

roller seals and bearing relief valve.

3.

Wipe excess grease away.

1

Figure 8

1. Relief valve

Adjusting the Reel Bearings

To insure long life of the reel bearings, periodically check if

reel end play exits. The reel bearings can be checked and

adjusted as follows:

1.

Hold on to the reel shaft and try to move the reel

assembly side to side (Fig. 9).

1

Figure 9

1. Reel shaft

2.

If end play exists, proceeded as follows:

A. Loosen external set screw securing bearing

adjusting nut to bearing housing located on the left

side of the cutting unit (Fig. 10).

1

2

Figure 10

1. Set screw

2. Bearing adjusting nut

B. Using a 1–3/8” socket wrench, slowly tighten the

reel bearing adjustment nut until no end play of the

reel exists. If adjusting nut does not eliminate reel

end play, replace reel bearings.

Note:

Reel bearings

do not

require pre–load. Over

tightening reel bearing adjuster nut will

damage reel bearings.

3.

Retighten set screw securing bearing adjusting nut to

bearing housing. Torque set screw to 12–15 in–lbs.