B.

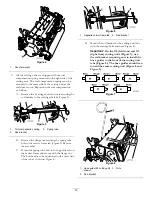

Insert the lift arm yoke onto the carrier frame

shaft (Figure 11).

C.

Insert the lift arm shaft into the lift arm and secure

it with the washer and lynch pin (Figure 12).

10.

Insert the cap over the carrier frame shaft and lift arm

yoke.

11.

Secure the cap and the carrier frame shaft to the lift

arm yoke with the snapper pin. Use the slot if a steering

cutting unit is desired or use the hole if the cutting unit

is to be locked in position (Figure 10).

12.

Secure the lift arm chain to the chain bracket with the

snapper pin (Figure 13). Use the number of chain links

described in the cutting unit

Operator's Manual

.

Figure 13

1.

Lift arm chain

2.

Chain bracket

13.

On the #4 (left front) and #5 (right front) cutting

units, insert the reel motor hoses into the respective

hose guide.

14.

Coat the spline shaft of the reel motor with clean

grease.

15.

Oil the reel motor O-ring and install it onto the motor

flange.

16.

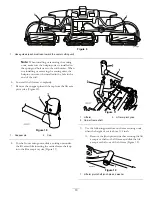

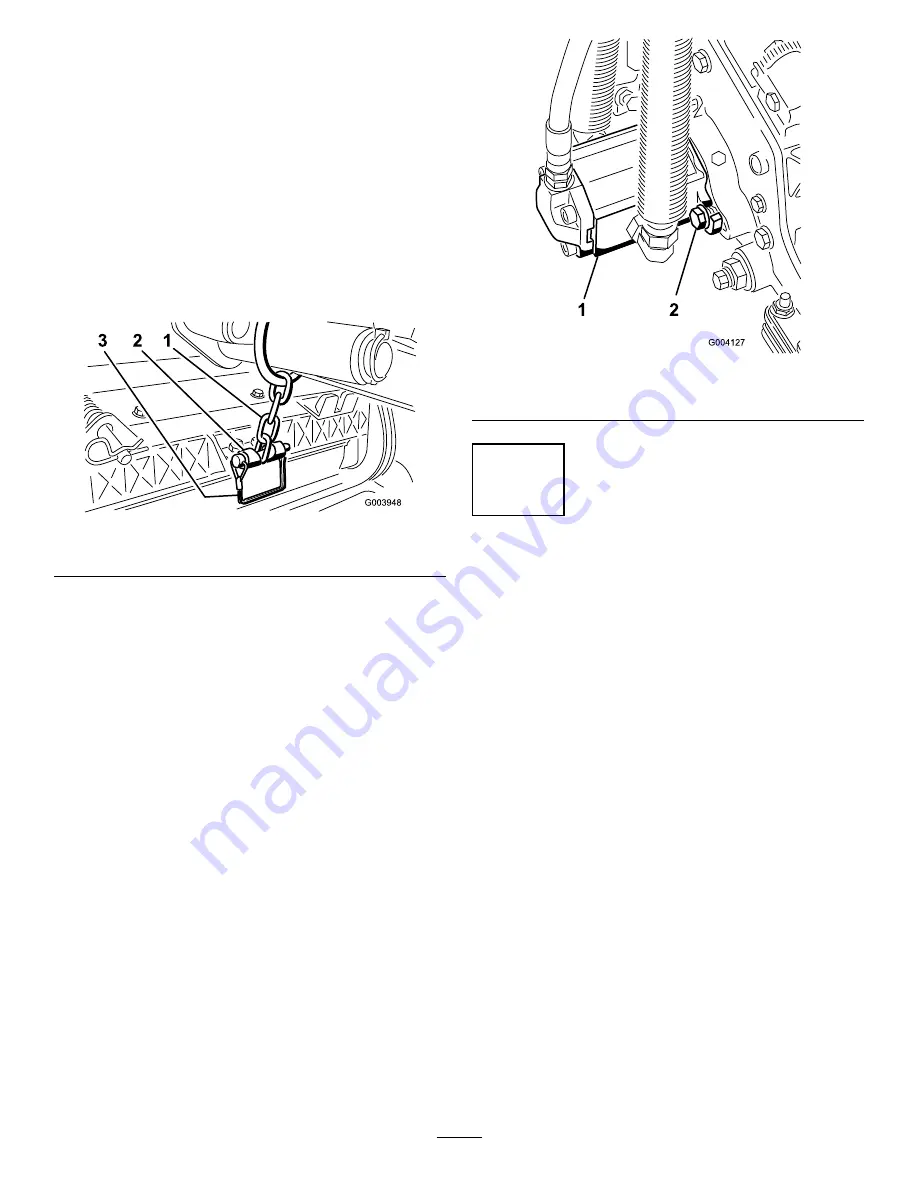

Install the motor by rotating it clockwise so that the

motor flanges clear the bolts (Figure 14). Rotate the

motor counterclockwise until the flanges encircle the

bolts then tighten the bolts.

Important:

Make sure the reel motor hoses are

not twisted, kinked or in the risk of being pinched.

Figure 14

1.

Reel drive motor

2.

Mounting bolts

5

Adjusting the Turf

Compensation Spring

No Parts Required

Procedure

The turf compensation spring (Figure 15) transfers weight

from the front to the rear roller. (This helps to reduce a wave

pattern in the turf, also known as marcelling or bobbing.)

Important:

Make spring adjustments with the cutting

unit mounted to the traction unit, pointing straight

ahead and lowered to the shop floor.

1.

Make sure the hairpin cotter is installed in the rear hole

in the spring rod (Figure 15).

14

Summary of Contents for 03673

Page 46: ...Notes 46 ...

Page 47: ...Notes 47 ...