7

3. Stop the traction unit and remove the key. Manually

pull the lift arms, one at a time, to floor level. Repeat

this procedure for the #4 and #5 cutting units.

Without the cutting units installed, restarting the

engine will result in the lift arms raising.

Caution

4. Roll the appropriate cutting unit to lift arm and match

the male end of pivot arm with hole in lift arm.

Note: It may be necessary to spread slotted block on lift

arm slightly to slide pivot arm fully into hole.

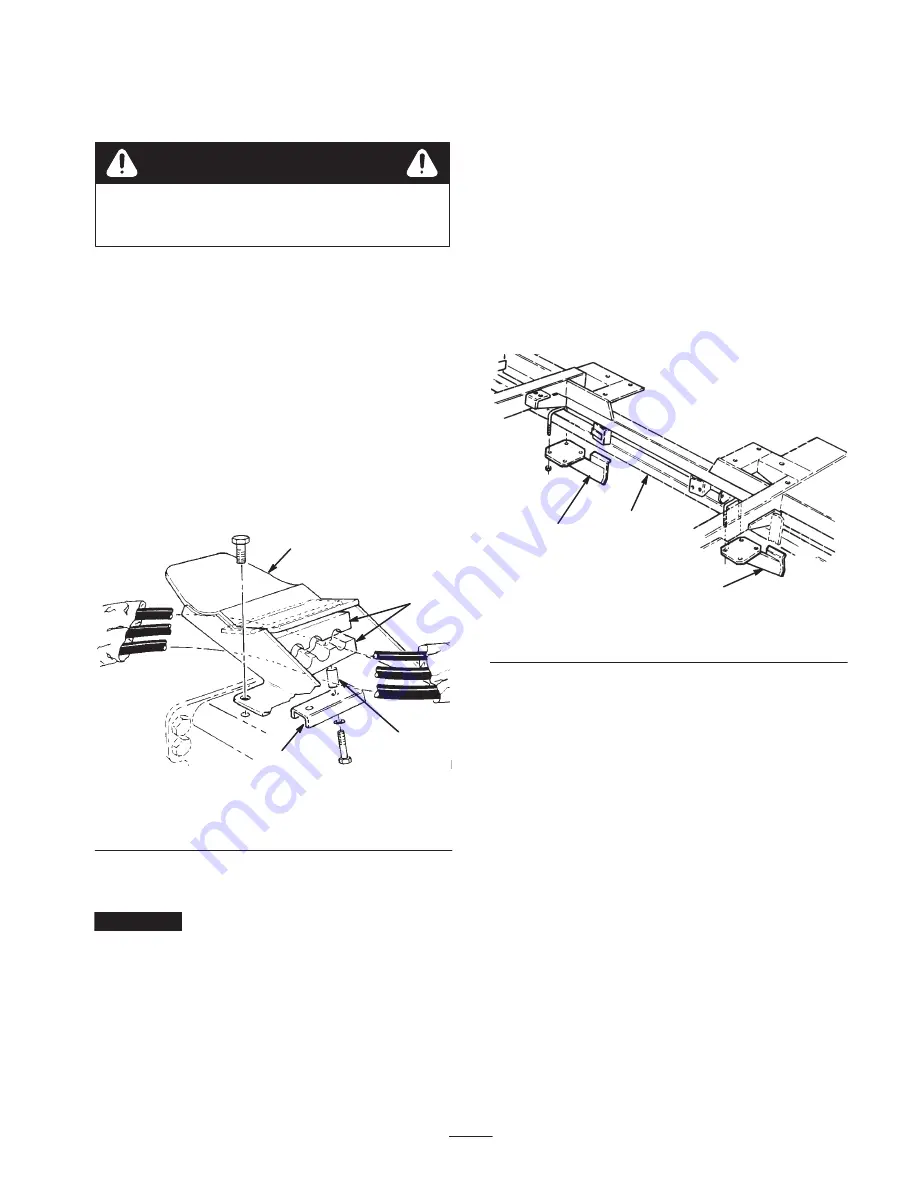

5. Reinstall 3 lift arm bolts but do not tighten (Fig. 5).

Mounting the #4 and #5 Tipper

Brackets

1. Loosely secure the hydraulic hoses to the underside of

each tipper bracket with hose clamps, spacers, clamp

plate, lock washers, and capscrew as shown in

Figure 7.

1

2

3

4

Figure 7

1.

Tipper bracket

2.

Hose clamp

3.

Spacer

4.

Clamp plate

2. Mount tipper brackets to cutting units with capscrews

and locknuts.

Important

Raise and lower each cutting unit to ensure

that there is no binding of hoses during operation.

3. Tighten capscrews securing hose clamps to tipper

brackets.

Mount the Roller Bumpers

(Floatation Kit Only)

Note: Roller bumpers are required only when operating

cutting units in the float position and front rollers are

installed.

1. Locate mounting position of roller bumpers (Fig. 8) on

each side of frame tube in front of #1 cutting unit.

2. Loosely secure a roller bumper to each side of frame

tube, as shown in Figure 8, with U-bolts and locknuts.

3. Align the center of each bumper with the respective

end of the roller on the #1 cutting unit and tighten the

locknuts.

1

2

1

Figure 8

1.

Roller bumpers

2.

Frame tube